Engineering Lessons

The uneasy relationship between tradespeople and architects is well known, but a bigger challenge many builders face is figuring out how to get along with a structural engineer.

Synopsis: A structural engineer is typically brought in when architects and carpenters reluctantly acknowledge that they are out of their depth. Scott McBride recalls instances of working with a structural engineer, and how an engineer’s plans can clarify or confuse a project. Whether because of information overload, strict building requirements, or unusual technical data, relationships between builders and engineers can be fraught with uncertainty.

The uneasy relationship between tradespeople and architects is well known. We are like cats and dogs, mutually suspicious denizens of the same backyard, prowling around for our livelihood in service to the same master or mistress. The contractor is like a faithful Fido

who goes chasing enthusiastically after every bone the owner tosses. “You want an exercise room on the third floor with quarry tile on the ceiling? Great idea! Sure, we can do that.” Meanwhile, the architect casts a cool feline gaze on the misguided meandering of the client and the builder. Stealthily she steers the discussion to a higher plane. Like the lisping Persian cat in the movie Babe, her “purputh” is to be beautiful.

But there is another animal who appears less frequently in the jungle of residential construction. Years may pass with nary a sighting of this rarefied creature, for he prefers the cooler climes of commercial construction. The blood in his veins runs ice cold, and he gives no heed to the shrill bark of a disgruntled carpenter or the screech of an architect whose masterpiece has just been compromised. A hired gun, he is brought in only when these lesser mortals reluctantly acknowledge that they are out of their depth. Stand back—the structural engineer has arrived.

My first experience with an engineer occurred while remodeling a decidedly cockamamie house for one of my best customers. The previous owner, an artist who was long on ideas and short on construction experience, had built the place in the days when my rural county had no building code, so there was no check whatsoever on the man’s “creativity.” I had already spent years off and on trying to rectify the unfortunate results, which included termite damage, siding failure, and an energy performance that was roughly inverse what it should have been. When my customer announced that he wanted to undertake a whole-house remodel, I threw up my hands. “Enough already!” I cried. “I can’t do this on my own.”

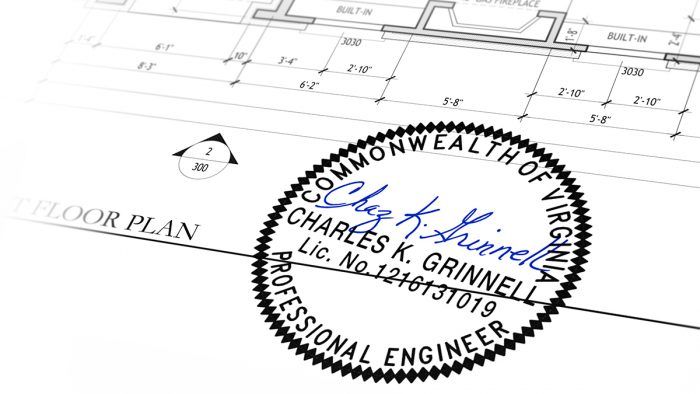

Fortunately, the owner, a software consultant, was on board with the idea of bringing in an expert to think through the various challenges, and so we contacted a PE (professional engineer). The guy was terrific. He sent out a draftsman with a laptop—a real CAD wizard—to record the existing conditions, and within a couple of weeks we had a fully baked plan to put this faltering structure firmly on its feet. Questions arose as the job unfolded, but the engineer was available to provide answers. When the project was completed, it was clear that the engineer’s fee was money well spent, and I had peace of mind knowing that every beam and footer was certifiably capable of doing its job.

By contrast, my next experience with a structural engineer was nothing short of a bummer. The project was a contemporary wing added to an old farmhouse, and the idea was to emphasize, rather than disguise, the transition from old to new. The addition featured a hybrid timber frame linked to a glass curtain wall by custom steel connector plates. An existing stone chimney —a prominent element now located inside the addition—was problematic because it had no footer. A mezzanine and spiral staircase also had to be accommodated, all jammed within a 20-ft. cube. Obviously, there was plenty of square-rooting to be done.

An engineer did a set of drawings which were appended to the architect’s design set, but as the job progressed there were structural issues that still needed resolution. It then became apparent that there was no clear understanding between the client and the architect

about who was going to pay the engineer for the followup work. I needed answers, but the client didn’t want to pony up. And here’s the rub: When the building department accepts engineered plans, primary decision- making about structural issues is out of the builder’s hands. When a building inspector sees an engineer’s stamp on the drawings, his ears prick up. The stamp means that the usual code criteria doesn’t necessarily apply. This lets the inspector off the hook for code enforcement as long as he enforces the engineer’s requirements. Woe unto the builder who says, “Well, there’s nothing on the drawings about how to fasten this mezzanine ledger, so I’ll just hang it like a regular deck ledger.” If he does, the inspector may arrive at the framing inspection and say, “So where are the engineer’s specs on that ledger?” If a description of the as-built assembly goes back to the PE for approval and he gives it a thumbs down, there will be a lot of work with a cat’s paw—a risk no experienced builder wants to take.

Another painful incident on this project involved erroneous requirements. The written specs called for special high-grade bolts. Sourcing these was a major headache. I had to go to an industrial supply house, sift through their stock, and back-order the sizes they didn’t have. The lead time for the back order held up the entire show. When I mentioned these difficulties to the engineer later, he expressed surprise. “You didn’t need special bolts for this,” he said. “But that’s what your specs called for!” I replied, choking back the ire in my voice. “Oh, well, that was a mistake.” I suppose an assistant in his office got a little careless with the cut-and-paste function. The takeaway: Question authority. If a specification seems onerous, it doesn’t hurt for the builder to push back a little to make sure the resulting quest for an exotic product is truly warranted.

There is another pitfall that awaits any builder who labors under the auspices of an engineer— information overload. You might think, “Gee, this is great. The geek does all the thinking while I go along for the ride, upping my game in the process.” Well, fasten your seatbelt, my friend. You are about to be inundated with a flash flood of tables, technical jargon, and unfamiliar specs that will make your head spin. And you need to understand every word of it—in a hurry.

I had a client who originally wanted a timber-frame home, but he grew tired of waiting on his architect. I ventured innocently that the wide-open interior spaces he desired could be achieved with engineered lumber. The client liked the idea, so the architect’s preliminary drawings were sent to an engineer for a framing plan. Engineers love engineered lumber such as LVLs and I-joists because performance data is readily available with far fewer variables than solid wood. I had experience with most of the products the engineer specified, except one—a PSL post. Parallel strand lumber is a layered product, like OSB, that is produced in dimensions suitable for posts and beams. This job called for two 20-ft. PSL posts supporting a triple LVL ridge over a high-ceilinged foyer. The posts also carried girders for the second-floor joist system.

All of this had already been framed when late one night I was reviewing the manufacturer’s technical data on my computer. I reached the bottom of the page, which I had read through many times, when my index finger must have rolled on the mouse and suddenly I realized there was another page that I had not read before. curiously I scanned it to the bottom, where, in small type—almost like a footnote—was the brief admonition: All fasteners into the PSL posts must enter perpendicular to the chip layers, not between the layers. I hadn’t given this the slightest thought! I suddenly saw disaster barreling toward me.

I did not sleep a wink that night. Waves of nausea rolled over me as I headed to the job in the cold light of dawn. The project was located far back in a mountain hollow, giving me plenty of time to weigh my options if the dice rolled the way I was sure they would. Bankruptcy surely wouldn’t be that bad. Or I could escape to Mexico and start a new life.

Pulling up to the site, I flung the truck door open and clambered up a ladder to the first floor deck. I peered frantically through the mist in search of fate’s verdict written on the side of the nearest post. Would I see chunky chips or layered lines where the hangers were fastened? Wait—could it be? Yes! I was saved. Both posts were oriented the right way—no thanks to me.

Don’t get me wrong. I have the utmost respect for the engineer and his knowledge. I have seen buildings fail, and it’s not a pretty sight. But to survive in the jungle, it’s a good idea to know who you’re dealing with before you stick your head in the lion’s mouth.

From Fine Homebuilding #283

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Reliable Crimp Connectors

8067 All-Weather Flashing Tape

Handy Heat Gun