Podcast Episode 180: Rigid Foam Over Roofs, Warm-Climate Insulation Details, and Fuel-Efficient Work Trucks

The Fine Homebuilding editors discuss some upcoming articles about building sheds and installing custom metal stairs before addressing listener questions about insulation upgrades, environmentally responsible transportation, and more.

Follow the Fine Homebuilding Podcast on your favorite app. Subscribe now and don’t miss an episode:

|

|

Patrick, Matt, and Kiley start today’s conversation with details about two recent photo shoots for the magazine–one in Cooperstown, NY, where Matt captured a steel-framed, walnut-treaded modern staircase installation; and another in Kiley’s own backyard, where fellow FHB staffer Rob Wotzak built a small but elegant woodshed of his own design. Then it was on to several questions from the Fine Homebuilding inbox, including one from a listener who wonders how we can constantly talk about building energy efficient homes without mentioning the gas-guzzling trucks we travel to the job site in every day.

Reader Feedback

Astounded by the cost of kitchen remodels

Doug from Colorado writes: Just watched podcast 170 and as always it was full of interesting info. I strongly agree with the comments about the cost of cabinets. Anytime I watch one of the home improvement shows on TV I am astounded by the cost of kitchen remodels. When I built our house the total cost of materials for cabinets for the kitchen, bathrooms and large pantry was well under $3,000. These were all stain grade which meant hardwood plywood not MDF. On the other hand I got just enough done for the CO and then spent many months finishing the rest after moving in.

Skilled-trades and Form-a-drain

Andrew from Iowa writes: Hey guys. I’ve been a remodel contractor in Iowa since 2006. I appreciate all you’re doing to educate the public on building science, and best practices. I really enjoy the podcast even though it’s infuriating at times, and I end up screaming at my phone.

In podcast 170 you read a letter from Paul discussing the lack of demand for skilled trades. I don’t see the skilled trades gap. What I do see is a serious lack of “businesses” charging what needs to be charged in order to pay their workers a fair wage. There is a great demand for “skilled trades” at $15 per hour, but ask for a living wage and you’re laughed out of the office. I don’t have any trouble getting help any time I need it, but then again I pay an honest wage.

On a previous episode someone mentioned loving “Form-a-drain”. In a former life I poured foundations and I can tell you it’s a great idea, but in the real world Forma-drain is a disaster. It’s brittle and difficult to work with. After it’s installed it’s prone to damage throughout the building process, and is basically unrepairable. If all goes well and it’s properly installed and makes it through undamaged, it fills up with dirt in record time. We never had call backs with perforated drain tile or PVC. Forma-drain was another story. The constant issues finally made our company to stop using it.

Editor Projects

Kiley’s outdoor projects: Tree removal, landscaping (Hollywood Juniper), and new woodshed

|

|

|

Patrick: Update on the use of Spray & Forget to remove mildew from his home’s siding

Matt: Trip to Cooperstown to photograph the installation of a custom metal and wood staircase

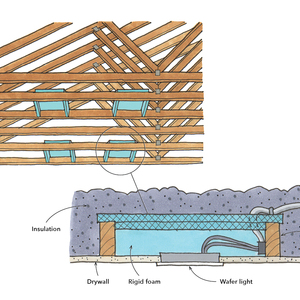

Question 1: Is it OK to insulate with rigid foam over old roof sheathing before reroofing a hip roof?

Adam from Indiana writes: Hi FHB Podcast! Long-time listener of Fine Woodworking who recently found the FHB the podcast which is fantastic. I’ve been scouring past episodes looking for conversations about roofing and insulation.

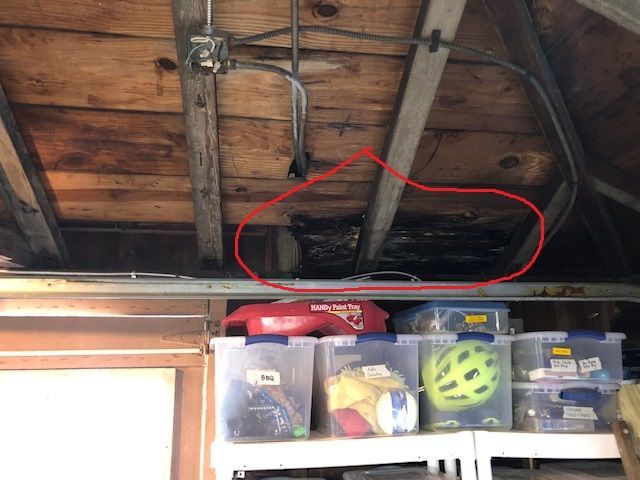

The Southern Indiana house that I’ve lived in for a decade, was built in 1936. It’s a unique, small 2-story brick house with a detached 3-car garage connected by a breezeway. It has beams from an old church in the living room ceiling. The first floor has steel floor joists, which I have never seen before in a home. I remodeled the house when I bought it, though we never did much to the garage, which we use as a workshop. The roofing on the home, garage, and breezeway has needed replacement for years. We are finally being forced to bite the bullet as the shingles have started to crumble and it’s leaking where the breezeway ties in.

|

|

|

|

|

We have considered insulating the garage many times, but a contractor/friend told us that there is not a large enough vent in the eves to allow for airflow from the soffit along the roof and out through the ridge vent, if we did insulate. Recently, I heard you discussing using rigid foam insulation on the roof, but haven’t seen this done before in practice, which brings me to my question:

Is rigid foam insulation on the roof a good idea for a situation like ours, where we are needing a new roof anyway, and since there is zero insulation to be found in the house or garage already? If so, is it a common enough practice that I should be able to find roofers in my area familiar with how to do it?

Or, if I decided to get some friends together to replace the roof ourselves, which would satisfy my DIY soul, what are the high level steps to proper installation of the rigid foam insulation?

Thanks for in advance for any great advice! In the meantime, I’ll be in the library searching FHB books and magazines.

Related links:

- Retrofitting Foam Insulation on a Roof

- Insulating Unvented Roof Assemblies

- Rigid Foam on the Roof and Walls

- An Unvented, Superinsulated Roof

Question 2: How can I figure out which durability and energy-efficiency details make sense for my home in Southern California?

Joseph in Southern California writes: Hey guys, A couple questions… feel free to answer just one if it’s too much 🙂

- I like the idea of Zip sheathing for many reasons, but it bothers me that the primary method of sealing the joints (the tape) laves you unable to “shingle” the layers to ensure that bulk water dam-up at the top of the tape-seam. Why don’t they just sell a product that leaves 4-6″ of the waterproofing layer proud/overhanging the sheet good so it will work naturally? You could easily use their liquid flashing product to air-seal the joints in combination with this.

- Living in southern California, it seems most builders here treat many of the energy efficiency products as overkill. The rain we get comes in short spurts and dries quickly, and we get plenty of sun so those who can afford upgrades tend to opt for solar and continue to let their leaky houses waste energy….and the expensive houses use a simple housewrap with no exterior insulation (in 2×4 exterior walls with fiberglass batts), and most older houses have the standard 2 layers of paper with stucco applied directly (no sheathing). The roof seems worse…black asphalt shingles and poorly ventilated attics, with poor air sealing between the house and attic. Given the climate, what are the best methods to use? Most of the online resources I find are focused on homes in colder climates, and I’m not sure what methods are still well suited for a hot dry climate. I’m hoping to do a big remodel and addition on my next house and would love to better understand how to get the best value for my climate. Any specific resources I can go to for more info would be greatly appreciated!

- Rainscreens/ventilated wall assemblies seem like a great fit for any climate, even a hot/dry one, because the air movement will provide a cooling effect in a hot climate…but it seems to not be a generally done here because of the fire risk…is there any way around this? I’ve been dreaming up ways to make the whole assembly out of fireproof materials, but I’m wondering if I’m missing a key factor here…is the gain to be had negligible in this type of climate?

Love the podcast, I listen on my commute and love learning from you guys, please keep up the great work.

Related links:

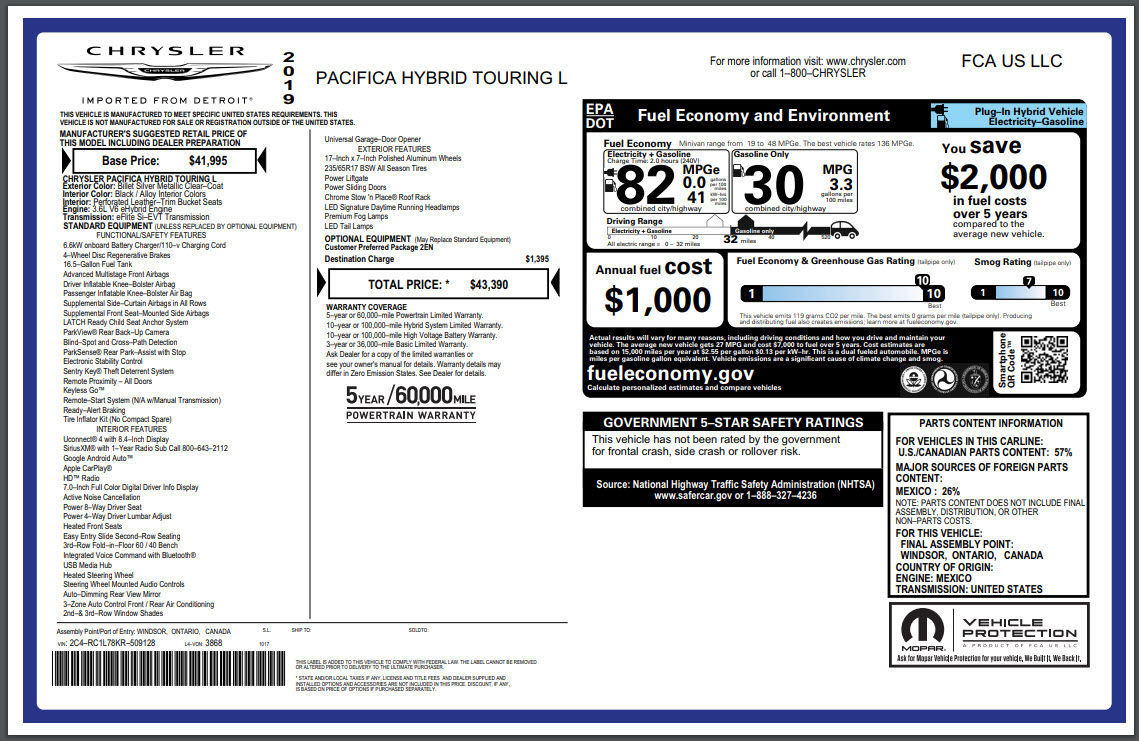

Question 3: Demand for a sustainable mode of transporting our tools and materials?

Henrik Writes: Green building vs getting there and home?

I just went through the full list of all the podcasts you guys have produced and didn’t see one episode on the vehicles we builders use to get ourselves our tools and materials to and from the job site. Is no one concerned with this? I spend, on average, $600.00 a month on gas! I put over twenty gallons of fuel into my van twice a week. That means I’m putting something like 250 lbs of CO2 and other pollutants into the atmosphere each week!

It’s completely hypocritical of me to try to build an energy efficient structure when I’m spewing all this s*#t out of my exhaust pipe! But when I search for a sustainable cargo vehicle, I find nothing! You guys there have an opportunity to start a conversation on increasing the demand for a sustainable mode of transporting our tools and materials. Why don’t you do so?

I have an eight year old. I don’t doubt you guys have children. Do you have no concern for our ecological futures? I suspect you are more concerned with pleasing your sponsors, so you have no incentive to start any sort of conversation on the vehicles we use because no vehicle manufacturers in the US are advertising practical electric vehicles for our industry on your channel. I’ve seen plenty of ads on FHB for gas guzzlers. How about we work on increasing the demand for an electric alternative? I suppose I already know the answer. If you respond to me at all it’ll be to call me a hippie dreamer or question my manliness; after all what self-respecting macho hammer wielding grunt would even think of driving an all-electric vehicle to a construction site?

|

|

|

|

|

Related links:

- How much carbon dioxide is produced from U.S. gasoline and diesel fuel consumption? (from eia.gov)

- 2019 Most and Least Fuel Efficient Trucks, Vans, and SUVs (fueleconomy.gov)

- Average Fuel Efficiency of U.S. Light Duty Vehicles (bts.gov)

Question 4: Should I enclose the furnace and water heater in my workshop for fire safety?

Ian writes: Hey guys, Thanks for making the podcast I really enjoy listening on my commute and while I’m in my shop, I’ve learned a lot. I have a little building experience from living in the northeast, and I’ve recently moved to zone 4 in Albuquerque NM and I converted the two car garage to a wood shop. My questions is regarding the gas fired furnace, and water heater that are in the garage. While I have dust collection, I’m considering building a sealed closet around them to protect the appliances and to provide adequate combustion air that I don’t breathe. In my search for details online some people seem not to care about the dust etc. while others are quite concerned. Neither side offers a solution.

I’ve only been able to find one article detailing the construction of this closet with a high low air inlet and I’ve attached a link below. I’d like to hear y’all weigh in on the construction of the closet, like sizing the inlets and location of them in proximity to the exhaust at the roof, fire breaks at the ceiling, sill seal at the bottom plate, space around the appliances for maintenance access, and maybe what kind of gaskets at the door and threshold. I’m considering doing some finishing in the shop with oil applied varnishes, shellac etc., and would like to hear if this enclosure would be able separate the fumes from the appliances for fire concerns. Sorry that’s probably a lot packed into one question but hoping y’all will take a stab at it, because I don’t think I’m the only one facing this kind of question.

PS: Let me know if I’m just totally paranoid. Thanks again!

Related links:

- 3 Problems with Atmospheric Combustion Inside the Building Envelope

- Making Your Home Safer with a Sealed Combustion Closet

#KeepCraftAlive

Support the trades!

Buy a #KeepCraftAlive hat or t-shirt!

This episode of the podcast is brought to you by Windsor Windows & Doors, Protective Products, LP Outdoor Building Solutions, and Deck Wise

This episode of the Fine Homebuilding Podcast is brought to you by Windsor Windows & Doors. Put your personal touch on your next home construction or renovation project by using Windsor Windows & Doors. Offering a full line of Wood Clad, Cellular PVC and Vinyl Windows and Doors, our products come in a wide variety of colors, finishes and optional accessories that give you the perfect look to match your home’s style. With our quality construction and industry leading warranty, Windsor Windows & Doors are built to last. Get started on your next project by visiting WindsorWindows.com and find an authorized Windsor distributor near you.

Also brought to you by Protective Products:

The nation’s oldest, most trusted, direct-to-you supplier of Surface Protection and Dust Control. From industry-leading Econo Runner, protection for most hard flooring, to Zipwall, the contractor’s choice for building quick containment areas, Protective Products works with you to keep your jobsites protected and your customers happy. Show that you care about preserving your quality craftsmanship with their full line of Surface Protection and Dust Control Solutions, see it all at ProtectiveProducts.com.

And LP Outdoor Building Products:

Whether you’re looking to add a storage unit or an art studio to your backyard, LP offers beautiful and durable products that can help you turn your shed into a stylish extension of your home. Because at the end of the day, your shed says a lot about who you are. Why not shed it your way? For inspiration and to learn more, visit LPShed.com.

The Fine Homebuilding Podcast is also brought to you by DeckWise:

Does your hardwood deck need a makeover? Bring back the luster of the day it was first installed. Let DeckWise reverse time and erase its dullness to make the wood grains burst with natural beauty again. Start with our Wood Cleaner and Brightener and finish with our eco-friendly water-base formula, WiseCoat, or our low VOC Ipe Oil hardwood finish. Protect and preserve your deck to keep it looking brand new this summer! For more info on these products visit DeckWise.com.

We hope you will take advantage of a great offer for our podcast listeners: A special 20% off the discounted rate to subscribe to the Fine Homebuilding print magazine. That link goes to finehomebuilding.com/podoffer.

The show is driven by our listeners, so please subscribe and rate us on iTunes or Google Play, and if you have any questions you would like us to dig into for a future show, shoot an email our way: fhbpodcast@taunton.com. Also, be sure to follow Justin Fink and Fine Homebuilding on Instagram, and “like” the magazine on Facebook. Note that you can watch the show above, or on YouTube at the Fine Homebuilding YouTube Channel.

The Fine Homebuilding Podcast embodies Fine Homebuilding magazine’s commitment to the preservation of craftsmanship and the advancement of home performance in residential construction. The show is an informal but vigorous conversation about the techniques and principles that allow listeners to master their design and building challenges.

Other related links

- All FHB podcast show notes: FineHomebuilding.com/podcast.

- #KeepCraftAlive T-shirts support scholarships for building trades students. So go order some shirts at KeepCraftAlive.org.

- The direct link to the online store is here.

View Comments

Interesting question about electric or low emissions work vehicles. The two vehicles that come to mind are the Tesla electric semi and the Rivian pickup (https://products.rivian.com/). While neither addresses this specific application, nor do they exist yet on the market, and both are expected to be very expensive, perhaps they are both are starting to show the feasibility of electric power for larger vehicles.

In regards to the discussion about positive lap on zip sheathing I think ship lap joints would be a better solution than tongue and groove.

I enjoyed the electric or low emissions work vehicles discussion. Nobody talks about the environmental impact that mining has to make the batteries to run these electric vehicles.We dig up thousands of pounds of stuff to process to make the batteries, digging up is done with oil, by big machines, so we're consuming energy to save energy.

Then we have to plug it to charge the batteries with electric that comes from coal or natural gas power planes or a nuclear power plant that has no carbon foot print.

A fun fact more people have died falling off roofs installing solar panels then from nuclear power accidents.

Agree that we need to look at the cradle to grave impact of electric vehicles vs gasoline vehicles, but disagree that "nobody talks" about the mining and manufacturing aspects. One need not go any further than Wikipedia for a good summary of research done to date on the topic:

https://en.m.wikipedia.org/wiki/Environmental_aspects_of_the_electric_car#Environmental_impact_of_manufacturing

The most recent studies seem to indicate that the overall emissions from electric vehicles is about half that of gas powered vehicles, although it will vary depending on many factors including, as you point out, the source of electricity for charging the vehicles.

Looking for links to the stories Kiley referred to about low-cost/high-impact kitchen remodel tips. Maybe I'm blind, can someone direct me to those links? Thanks--great show!

Sorry Audiobrad, here's the link: https://www.finehomebuilding.com/2017/10/16/kitchen-remodel-20k

I don't know the cost involved, but it seems like BSI-068 (https://www.buildingscience.com/documents/insights/bsi068_rocks_dont_burn) from Building Science corp, presents a good option for a vented roof assembly in a wildfire zone, etc.

Then again, since the question is coming from a warm climate, and is unlikely to have ice dam issues, maybe the better/cheaper answer is just to make it unvented.

The work vehicle discussion is an interesting one. Smaller vans like the Transit Connect can be a great option for many trades, though I think a lot of people believe they need more truck than that. Full size vans can be more practical than a truck and some have more fuel efficient diesel options available. As a nice bonus, vans are typically a much better value on the used market when purchasing. Electric trucks are coming, but not here yet. https://workhorse.com/pickup/ is one, Rivian and Tesla are others. I expect GM and Ford will have options soon as well too. Another option is https://www.xlfleet.com/ to add a hybrid system to a truck or van. Probably not cost effective for most but it's an option for those really invested in making improvements.