Podcast 188: Smoothing Plaster Ceilings, Enforcing Airtightness, and Better Brick Walkways

The crew reviews feedback about carpenter bees, home sprinklers, and grade-level decks before taking questions on finding contractors for small jobs, removing textured ceilings, and blower-door testing.

Follow the Fine Homebuilding Podcast on your favorite app. Subscribe now and don’t miss an episode:

|

|

This week’s installment revisits Tony’s planned grade-level deck and we hear from a listener who’s married to a carpenter bee researcher. The crew explores the best way to remove ceiling stalactites and how to convince a carpenter to take on a small rot-repair job. Then they hear from a home-performance contractor irritated by the lack of airtightness testing in Northern New York and discuss how to keep a brick walkway looking good.

Reader Feedback

Tony’s question from Podcast #185 where we discussed his plans to build a ground level deck

Tony writes, Guys/gal/particularly Matt, I feel like I need to defend my question about a ground level deck.

I was apprehensive at first since I haven’t used but it seems like this will suffice and solve our problem.

Every patio I have ever done we install 6-8” of compacted gravel. More for any drivable service. For this size of a space at 6” depth of base that is about 5 yards of gravel and a yard of sand. About 13k lbs in material to bring in prior to pavers. No questions about that. Any less is a disservice to the customer. Let alone the excavation of the existing soil to get to depth and where that goes. I imagine Matt just didn’t know this. You don’t just plop down “bags of gravel” as suggested. That would be nearly 200 bags. This all had to be brought from the road through a side yard and around 2 adjacent town-homes over their finished yard spaces. Wheelbarrows or equipment tearing up their space. Lumber could be carried back on shoulders in a few trips. Much less intrusive.

My apologies if that wasn’t clear but I’m guessing you haven’t constructed a patio before. There’s a lot of material.

From Paul in Annapolis, MD, I heard your comments on sprinklers, In the state of MD all new construction and major remodels require sprinklers. This included homes on wells. The requirement requires a 500 gallon water tank and dedicated pump for the sprinklers. A standby generator is also required.

Our school community lost 4 students and their grandparents to a fire in a home that did not have sprinklers. I would retrofit my hose if it was feasible and affordable.

My wife Elsa Youngstead is a professor in the Applied Ecology department at N.C. State. We have collaborated on research about carpenter bees and how to prevent/ discourage carpenter bee nesting. She is currently conducting research to see what wood hardness the bees won’t drill into. (Depending on how quickly they find the experiment, it could be a few years before we have results, though.)

She is also currently putting together a survey about carpenter bees to document peoples’ carpenter-bee-related attitudes, concerns, expenses, and so on. If you were interested, you guys could potentially help promote it to your listeners when ready. The more input, the better!

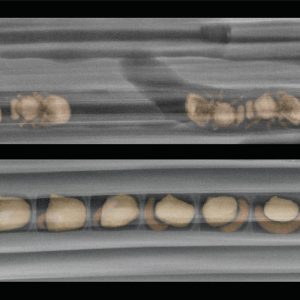

Attached photo is an enhanced x-ray of some nests. They do some serious damage.

Editor Projects

Kiley: Found a carpenter!

Matt: Clear roof panels for his shed.

Patrick: Paint and fabric swatches for the bedroom.

|

|

|

Question 1: What’s the deal with contractors?

John from New Jersey writes, Hi guys, Two years ago, my wife and I bought a 1935 Colonial in northern New Jersey. I’m an avid DIYer and try to do a lot of work in and around the house myself, but I know my limits and when it’s better to hire a contractor.

I recently found significant rot in the corner post of our screen porch. The lower 4” is probably 30% completely gone and the rest doesn’t look like it has much to go. It has clearly been patched a few times and it’s time to just replace it entirely. I understand the fundamentals of what needs to be done to fix it, but lack the confidence and helping hands to do it myself.

|

|

I’ve been trying to find a local contractor to do this for the last week and a half. I’m not necessarily looking for the absolute best guy out there, but I don’t want a crappy hack job that will have to be redone in a few years. After phone calls and emails to numerous contractors, not one has contacted me back.

One of my calls was to a slate roofing contractor, who also does exterior carpentry and we’ve paid thousands of dollars to do work on the house in the last two years — first to inspect the roof prior to purchase and followed by general repairs and snow guard installation. He’s well known to be the best slate contractor in the area.

I don’t know if this job is the type of thing he wants to do, but he’s reminded me twice in the past he does exterior carpentry and his website states he does “All phases of exterior carpentry” and addresses “Rotten wood repairs on exterior trim details”. He hasn’t returned my call or email in over a week. I feel like I’m an ideal customer – I’m interested in discussing details of the work beforehand but let them do the work without getting in the way (I wasn’t even home when he did the roof repairs), pay in full promptly, thank him for the great work afterwards, and recommend him any chance I get. I know he’s busy, but I just don’t understand why I don’t deserve the courtesy of a call back. I haven’t felt this rejected since dating in high school.

It’s not often I have to hire a contractor, but every time I do it’s the same story. I am left wondering, “are they just too busy right now?”, “is this below their minimum acceptable job?”, “are they simply not checking their email or voicemail?”. I can’t recall the exact quote, but in an earlier episode of the podcast, Justin mentioned something along the lines of “if you have to follow-up with a contractor, he’s not interested in the job”. Do you think that’s true? Should I keep trying or move down the list until somebody wants the job, even if that means hiring a subpar contractor?

How can I get a contractor to call me back, even if the answer is “sorry, I don’t want this job”? I get it and would be fine with that, but I just want closure.

Separately, any tips for finding other people like me who are interested in doing this type of work ourselves? We live in an affluent area where few people can be bothered to even mow their own lawn, so neighbors unfortunately are not an option.

Related links:

Question 2: What’s the best way to update my textured ceiling?

Paul from Las Vegas writes, Hey guys, first and foremost thank you for being such a valuable resource. I’ve spent more time than I care to admit listening along and reading through the forums.

I have a 1950’s single story that I’m remodeling. The ceilings and walls are all plaster with metal diamond lath. The ceilings have an extremely heavy stipple, with some “peaks” reaching an inch long. While they’re in great shape (zero cracking or separation), they are wildly hideous. I believe most of the ceiling is unpainted, but some areas definitely have a latex paint where an addition was done in the 90’s. I’m pretty capable with a drywall knife and mud, but don’t have any experience in plaster. My question is what’s my best material choice for skim coating the ceilings? Can I use joint compound against the plaster? Quickset as a first coat and topping compound as a final coat? Or do I have to go with plaster? I also haven’t ruled out covering the whole thing with 3/8’s drywall and/or ripping the whole thing out and starting from scratch with drywall. Any input is appreciated in advance!

Related Links:

Question 3: How can we push inspectors to require a blower-door test?

Noah from Upstate NY writes, Hello Fine Homebuilding Crew, I am a partner with a home performance contractor in Upstate NY, the real Upstate, where it is easier to get to Canada than it is to get to Albany. My big issue and the question I wanted to bring up has to do with code enforcement and the general lack of knowledge that surrounds the energy auditing profession.

I have found that code enforcement in rural areas is still not enforcing the envelope tightness tests that have been required since the state adopted the 2015 IECC codes. Most say that they don’t want to add another cost for builders and a shortage of inspectors makes it nearly impossible to replace a code enforcement officer.

The cost to run the test is negligible in comparison to the cost the new homeowner will have to heat and cool a leaky home. By not requiring the test, they are creating brand new homes that are potentially leaky, inefficient, and unhealthy.

Do you think the building industry is doing enough to educate builders and homeowners about the resources available for testing? What can be done to push inspectors to require the test?

These are just my questions that have to do with new construction. I feel like the trades far too often go into a home without a complete understanding of the system, they end up making recommendations that fix papercuts when there are still bullet holes in other parts of the home.

Thank you for your time and everything you do to make the podcast every week,

Related links:

Question 4: How can I restore my brick walkway?

Andy from Norfolk, VA writes, Dear Fine Home Building Podcast, I have enjoyed the podcast. I just finished listening through all the episodes. As a DIYer with moderate skill, I have used the podcast and the links you post online for a bit of a crash course in home building. I am in the process of converting a 1924 leaky home, which I purchased about a year ago into a Net Zero home. I’m working with a building scientist out of Charlottesville, VA so I have most of the air sealing and roof venting plan down.

|

|

|

However, my question is more about the aesthetics. My home has a large brick walkway leading up to my home. The oldest photo I could find is an aerial photo from 1978, so I know the bricks are at least that old, but not the same type of brick as the foundation. While the foundation of the home is a lime based mortar, the steps on the front of the home, and the walkway are some type of portland cement. My question is about how to restore the actual walkway. The bricks of the walkway are still in the correct spot, they have not sunk or moved. However, the area between the bricks is overgrow with grass. I can’t tell if there was mortar there, or just sand there. Do I repoint with a portland just like it was a wall? I’ve head of polymeric sand being brush in, but the manufacturer website of Sakrete’s product said “do not use on clay brick, as it may stain them.” Any ideas? Thanks in advance for your time.

Related links:

- The Brick Industry: Technical Notes on Brick Construction — Stains

- Weed Dragon

- Aliance G2 Rapid Set Intelligent Polymeric Sand

Recommendations for using polymeric sand on clay bricks from Hardware Building Supplier Dealer:

- Red clay bricks are a candidate for staining under any conditions, so it’s best to avoid them.

- Before you apply the sand, you’ll want to make sure the pavers are completely dry most of the way through if you want to avoid staining. This means waiting if you’ve just used a pressure washer, or if it’s rained recently.

- It’s important to remove all of the dust created when you put the sand down. After you have swept everything that you can into the joints, a leaf blower set on low and held at about a 30-degree angle will gently remove excess dust. This dust is what causes the stains once it is wet.

- When watering, it’s important to add enough water to saturate the sand but not so much that you float the polymers out of the sand. The most effective way to do this is to adjust the nozzle to “shower” and water the pavers until no more water will soak in. Spray for a few seconds, then stop and observe. If the joints continue to take water, keep spraying. When they won’t take any more water, and before you float the polymer out of the sand and onto the pavers, stop spraying.

- To protect your finished patio while it’s setting, cover with a plastic or tarp. Make sure to redirect pedestrian traffic for 24 hours and vehicular traffic for 72 hours.

Closing Points:

The Marketplace Morning Report for June 25, 2019 discusses this year’s shortage of new houses. Harvard’s Joint Center for Housing Studies says the US is not building enough housing— 1.2 million homes a year vs. 1.5 million. Reasons cited include land prices and material costs and a shortage of skilled workers. Many workers permanently left the industry after the great recession and young people aren’t attracted to construction work. Women also stay away, comprising just 9 percent of the workforce. They also say the immigration crackdown has also affected the labor supply. The result means most residential construction is focusing on the higher end.

Related Links:

Learn more and register for the Fine Homebuilding Summit.

#KeepCraftAlive

KeepCraftAlive hats help celebrate the value of true craftsmanship–plus 50% of all proceeds from every hat sold go to the #KeepCraftAlive Scholarship Fund, supported by Fine Homebuilding and SkillsUSA.

Buy a #KeepCraftAlive hat or t-shirt

We hope you will take advantage of a great offer for our podcast listeners: A special 20% off the discounted rate to subscribe to the Fine Homebuilding print magazine. That link goes to finehomebuilding.com/podoffer.

The show is driven by our listeners, so please subscribe and rate us on iTunes or Google Play, and if you have any questions you would like us to dig into for a future show, shoot an email our way: fhbpodcast@taunton.com. Also, be sure to follow Justin Fink and Fine Homebuilding on Instagram, and “like” the magazine on Facebook. Note that you can watch the show above, or on YouTube at the Fine Homebuilding YouTube Channel.

The Fine Homebuilding Podcast embodies Fine Homebuilding magazine’s commitment to the preservation of craftsmanship and the advancement of home performance in residential construction. The show is an informal but vigorous conversation about the techniques and principles that allow listeners to master their design and building challenges.

Other related links

- All FHB podcast show notes: FineHomebuilding.com/podcast.

- #KeepCraftAlive T-shirts support scholarships for building trades students. So go order some shirts at KeepCraftAlive.org.

- The direct link to the online store is here.