Cover for Exposed Foundation Insulation

Prefinished foam-insulation products and stone or brick veneers are a presentable option for a visible foundation.

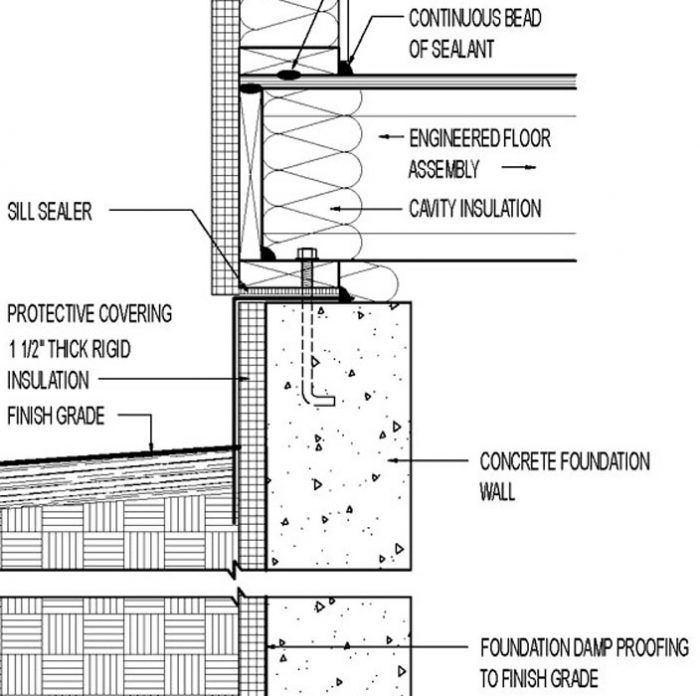

I’m fixing up my 1902 farmhouse and have added 4 in. of exterior polyiso to the wood-framed walls. I’d also like to insulate the exterior of the block-foundation wall with 2 in. of EPS or XPS foam since they can handle the moisture, but am at a loss about what to cover this with to make it presentable. I have about 16 in. of block exposed on one end of the house, and more than 40 in. on the other end. Are there options beyond metal flashing or parge coating?

—Jeff Newman via email

Deputy editor Matthew Millham responds: There are a lot of different products and materials that can achieve what you’re after, but first make sure your local code allows exterior rigid foam on foundations. Some locations don’t permit it because it can be a pathway for insect intrusion. If you’re in an area with termites and they let you do it, look for foam that’s treated to resist insects, and make sure to install termite flashing.

You may also want to leave a termite inspection strip at the top of the foundation Taking termites out of the equation, I’m a fan of all-in-one solutions. There are numerous foam-insulation products that come with protective finishes already on them. WallGuard from T. clear corporation is one—it comes in 2-ft. by 4-ft. XPS panels with a tongue and groove on the long edge and a 5⁄16-in.-thick latex-modified concrete face. The panels attach with clips, creating what looks like a panelized concrete wall. At least a handful of other manufacturers make similar products with different finishes and methods of attachment.

There are also products that can be applied to the foam after it’s installed that are similar to a parge coat but are more flexible and less likely to crack. Most require a layer of mesh either over joints and corners, or over the entire surface of the foam. Styro Industries’ Tuff II is a popular pick in this category and can be applied with a trowel or a drywall knife, or sprayed on. It’s 100% acrylic and can be custom-tinted just like paint, and it’s strong enough to take a hit from a weed whacker.

Stone and brick veneers are another popular option. Installation details will vary based on the product you choose, but a common approach is to attach galvanized lath through the foam to the foundation with concrete screws and washers, then apply a scratch coat of mortar and the veneer over that. You’ll want a good mason to do this so it looks good and lasts. Panelized veneers, like Boral’s Versetta Stone, have a similar look to adhered veneer, but can be attached with concrete screws. I should point out, though, that manufactured stone-veneer products generally can’t go all the way to grade, so you may need to use something else to cover the foam in that gap.

These are just a handful of possibilities, and not a complete rundown by any stretch. Depending on your choice, you may have to include some kind of flashing atop the foundation insulation to keep water out. And if you’re digging down to the footing to insulate the entire foundation, take the opportunity to look for and repair any problems with the block foundation, such as failing joints; add waterproofing (a foundation of this vintage likely wasn’t waterproofed when built); and, if there isn’t one already, install a perimeter drain that drains to daylight.

From Fine Homebuilding #289

More about foundation insulation:

Protecting Foundation Insulation – A heavy gauge of metal flashing offers increased durability.

Foundation Insulation Strategy – Our system has evolved as we’ve driven down costs while maintaining performance.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Foam Gun

Nitrile Work Gloves

Respirator Mask