Fix for Poorly Installed Window Flashing

When water is leaking in around newly installed windows, chances are that there are some missing or improper flashing details that need to be corrected.

We’re having a new home built and the windows just went in. Water is already leaking in around a lot of them, and I think I see why. The builder ran the housewrap inside on all four sides, then installed the windows and taped the flanges to the housewrap. We’re using Benjamin Obdyke’s HydroGap, which has a lot of tiny spacers to promote drainage behind the siding. I believe water is making it through the tiny gaps between the housewrap and flashing tape and following the housewrap into the house.

I cringe at the idea of pulling all the windows to flash them the right way—we don’t have the time or budget for it. I was thinking of two alternatives: either adding another layer of flashing using liquid flashing over the housewrap and tape, or cutting back the housewrap above each window a foot or so, flashing the flange to the sheathing, then tucking another 16 in. or so of housewrap under the cut and lapping it over the window flange. Are either of these ideas feasible?

—Kyle via email

Rhode Island builder and remodeler Mike Guertin (@mike_guertin) replies: You didn’t mention whether or not the window installers put flashing pans on the rough sills. My guess is they didn’t or you probably wouldn’t have noticed any water leaking in, since it would have just drained out. I’m also guessing that they applied sealant behind the windows’ bottom flanges, which will prevent any water that does leak in from draining back out. These deficiencies, along with the reverse-lapped head flashing you described, are probably code violations.

The IRC is pretty clear regarding window flashing, the goal of which is to keep water out of the walls. It offers a handful of options for achieving the required watertightness, the first being to install and flash the windows according to the window manufacturer’s instructions—code actually requires window manufacturers to provide them. Most window manufacturers, as well as water-resistive-barrier (WRB) and flashing-tape manufacturers, call for sill pans that drain to the exterior, as well as shingle-style flashing around the perimeter of openings and integrated with the WRB.

In the event that neither the window nor flashing company has instructions, the code prescribes that a draining sill pan be installed and that there be flashing or other protection around the sides and top of the window—all installed shingle style—to direct water to the surface of the exterior wall finish or to the WRB for subsequent drainage.

The code also acknowledges that there are lots of different ways to build, and it allows two other options as well: You can use a flashing design or method developed by a registered design professional, or you can use “other approved methods” of achieving the required watertightness.

Unless the installers can show you printed manufacturers’ instructions that verify the installation details they used are done according to the instructions or an approved alternative, I would have them remove the windows and follow the WRB manufacturer’s instructions to install the HydroGap and flash the windows according to the window manufacturer’s instructions. The installers were negligent, and it is up to them to correct the problem they created by not following the building code, at their own expense for both labor and materials. Yes, there will be a time delay, but there is no shortcut solution to remedy the problems the installers have created.

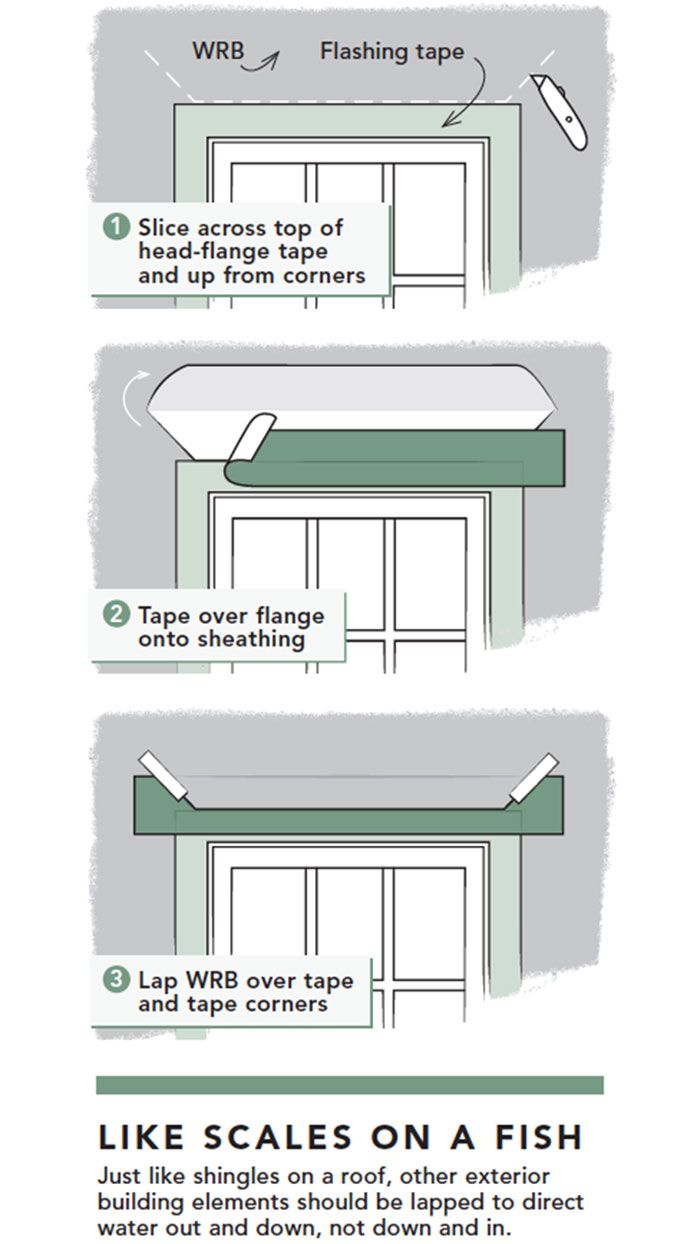

Now, if they did install a sill pan that is either sloped to the exterior or backdammed and there is no sealant between the bottom flange and the wall-face leg of the flashing pan, then the reverse-lapped head flashing can be remedied. Your second option is on the right track. Here’s my suggestion: Make a horizontal cut in the HydroGap across the top of the head-flange flashing tape. Then cut approximately 4-in. diagonal cuts in the WRB, radiating up from the ends of the horizontal cut. Lift the flap up and install a piece of self-adhering, self-sealing flashing tape that covers the original flashing tape and extends up 4 in. above the horizontal cut. Then fold the WRB flap down over the head flashing tape. This parallels HydroGap’s “method 2” installation guidelines.

If you have the installers make this repair, the labor and material expense is their responsibility—not yours—even if the project is being done on a “time and materials” basis. Paying them for repairing their negligent work just rewards them and encourages them to continue doing poor work without any consequences.

From Fine Homebuilding #289

More about flashing:

Shop Class: How to Install Nail-Fin Windows in 5 Common Wall Types – Builder Jake Bruton demonstrates trusted window-flashing details for walls with the following water-resistive barriers: Zip System sheathing, exterior rigid-foam insulation, housewrap, peel-and-stick membrane, and fluid-applied WRB.

Don’t Forget the Flashing – Easily overlooked and sometimes installed incorrectly, flashing keeps water out and rot at bay.

Waterproof Your Windows With Liquid Flashing – Learn how to install liquid-applied flashing to thoroughly seal a rough opening while also leaving a path for water to escape when it does get in.