Why Hand Tools?

The increasing number of power tools on the market make building easier, but learning how to work without them can make you a better builder.

Synopsis: Year after year, there are an increasing number of power tools on the market designed to save time and make building easier. But as Builder Scott McBride explains, getting hooked on power tools can mean losing sight of the advantages offered by hand tools, including maneuverability, dust control, and the understanding of why a power tools behave in different ways with different materials.

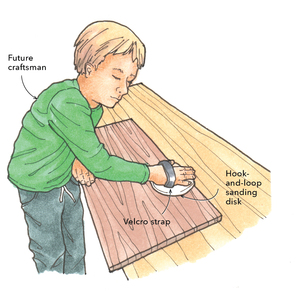

My daughter-in-law brought my five-year-old grandson for a visit the other day. After politely answering a few questions from his grandmother about kindergarten, the boy fixed me with a level gaze and announced the purpose of his visit: “Can I see your workshop?” Apparently he had heard rumors. I took his hand and we walked out back.

I pushed open the heavy sliding door to Grandpa’s very own walk-in toy chest and the boy stepped cautiously inside. Eyes wide with wonder took in all manner of potentially noisy and dangerous hardware— what a gold mine! He scurried from corner to corner, bouncing on his tiptoes here and there to peek over the tops of the various workbenches and machines. If he had a tail, it would have been slapping from side to side.

Our first project was nailing together two short blocks of cedar with 8-penny common nails. I stood on the ends of the blocks to keep them from bouncing while he clobbered the nails between my feet using a two-fisted grip on my claw hammer. After the twelfth nail he looked up at me inquiringly; “Yep, that oughta do it,” I said.

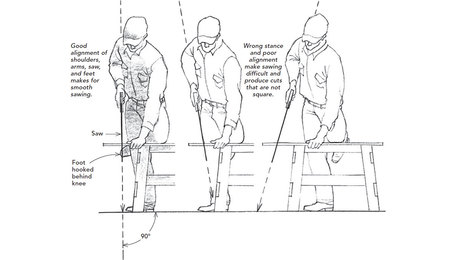

Now it was time to cut a board. I paused for a second, trying to remember where I kept the handsaws. Eventually finding one that wasn’t too dull, I blew off the dust and brought it over to the low sawhorses I had placed in the middle of the shop floor. I stood the boy in front of a pine board, and then encircled him from behind in the loose embrace with which my own dad had encircled me some 55 years earlier when I cut my first board—our left hands on the wood and our right hands on the saw.

I relish the swoosh of a keen block plane, or the purr of a 10-point obediently slicing through spruce. They’re among life’s simple pleasures.

Carpentry tools have changed mightily over that half-century, with power tools steadily pushing hand tools to the sidelines. Fortunately for my generation, we weren’t the first to connect to the grid. It fell to our fathers to grapple with the initial wave of clumsy all-metal beasts that strained back muscles and frequently electrocuted their masters (really!). Plastic housings were rapidly replacing metal in the 1970s when I started out, making power tools both lighter and safer. The biggest sea change during my career has been the steady march to cordless tools, a shift pioneered by Makita in the early ’80s that revolutionized the industry.

These general refinements, along with the development of ever-more specialized and compact iterations of the basic tool groups (saws, sanders, routers, etc.), have continued to improve power tools from one decade to the next. Before we abandon hand tools altogether, though, we should consider for a moment what we’re giving up.

One indispensable use of hand tools is teaching woodworking to kids. This hit me when my grandson visited. You can’t turn a five-year-old loose with a screaming circular saw. But waiting until a child is old enough to use power tools before getting them started in the craft seems a terrible waste of those early years, when a child’s mind is growing by leaps and bounds. Do we really want to devote all of that once-in-a-lifetime burst of cognitive power to video games? If the answer is no, then parents need to have the knowledge and the well-maintained tools to demonstrate that woodworking is an enjoyable, effective, and empowering discipline.

Another advantage of gaining at least basic hand-tool proficiency is that it enhances the use of power tools. For instance, operating a power plane without ever having worked with a hand plane is like stumbling around in the dark. Why is the tool cutting here but not there? The reason is slight variations in elevation that make planing a hollow surface completely different from planing a hump. You can’t see those variations, but with a hand plane you can feel them. For skillful planing you also need to understand the required shift in pressure from fore to aft as the tool enters and exits the work. These epiphanies are better grasped as tactile experiences than by sight alone. Similarly, when a hand plane becomes dull, you experience fatigue and a fall-off in performance throughout your entire body. In the knowing craftsman, this generates a sort of empathy toward his power tools. He is motivated to keep replacement blades and cutters on hand so he can change dull tooling before motors burn out, bearings are ruined, and everybody on the job site goes deaf.

In truth I’m as much a power-tool junkie as anyone. The first time I watched a Fein multitool blade plunge straight into a chunk of wood at a trade show, I practically fainted. How do I love them? Let me count the ways: Power tools are fast once they’ve been set up. They’re also precise when guided properly. Routing a hinge gain, for instance, is a tedious chore with a chisel, but it’s a snap with a mini router and template.

Pushing hand tools often requires clamping the work to hold it steady, whereas the momentum of power-driven tools can make clamping unnecessary. As a result, the heavy wooden sawhorses and workbenches of yesterday have been largely replaced by easily transportable plastic folding tables and skeletal saw stands.

Hand tools need cutters or teeth with an acute bevel to minimize power requirements, but power tools have the force to push cutters and saw teeth with more obtuse angles. That in turn permits the use of carbide— an alloy too brittle for acute bevels but many times harder than steel. Rotary planers and routers also produce less tearout than a hand plane because they take small bites rather than long shavings.

These advantages make power tools impossible to ignore, at least for the professional whose time is his most precious commodity. But getting hooked on power tools can mean losing sight of the advantages offered by hand tools under certain circumstances.

Doing punchout work inside a finished home calls for major dust control. The ability to deepen a hinge mortise by hand or block-plane an ill-fitting cabinet door can mean way less prep beforehand and easier cleanup afterward. There’s also less gear to carry in and out, and less noise if the owner happens to be in the next room watching television.

Handsaws have numerous advantages over their electrified cousins, including light weight and maneuverability; suppose you’re lying on your side in a crawlspace doing termite repair and need to trim a few inches off the bottom of a damaged post. A circular saw won’t fit and a reciprocating saw will make a mess, but a sharp handsaw will do the job nicely.

When cutting easily chipped material such as plywood, it’s desirable to have tearout occur on the back side. Not only will tearout be hidden that way, but the cutline on the face will be easier to follow. Western handsaws accomplish this by cutting on the push stroke, whereas circular saws and most jigsaws cut upward, causing tearout on the face. If the board in question has closed ends, such as a window seat, you can also make a slight undercut with a handsaw so the board fits easier—without having to make any bevel adjustments to the tool.

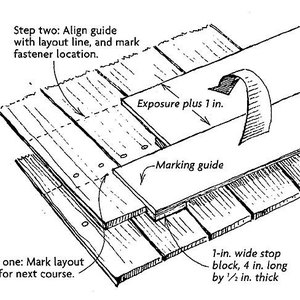

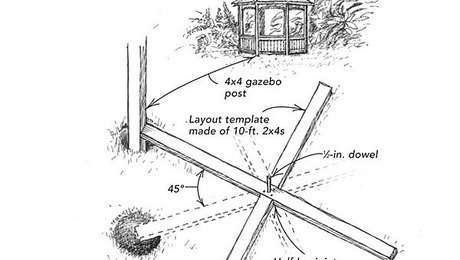

Speaking of bevels, handsaws also simplify compound cuts, especially when there aren’t enough pieces involved to justify a machine setup. I remember watching an old-time carpenter cut the bird’s mouths on the pickets for a porch stair using just a T-bevel and a handsaw. The job was done in less time than it would have taken me to set up a miter saw.

Finally, there is the sheer pleasure of using well-tuned hand tools. No, I’ll never be one of those guys in Fine Woodworking magazine with a cherry-paneled shop that looks like a Woodcraft Supply showroom. “Git ’er done!” is the carpenter’s battle cry. But I do relish the swoosh of a keen block plane, or the purr of a 10-point obediently slicing through spruce. They’re among life’s simple pleasures . Even in 2020, I think there’s still room for that.

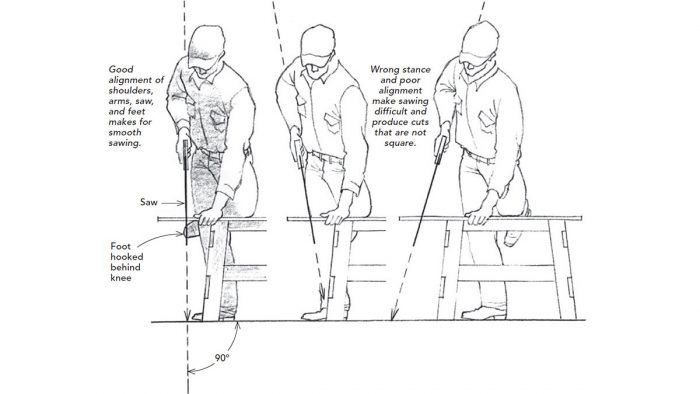

Drawing: Copyright 1982 by Aldren A. Watson from Hand Tools: Their Ways and Workings

Note: Fine Homebuilding may make a small commission on purchases made through the Amazon links in this article

From Fine Homebuilding #289

More about hand tools

Return of Some Classic Hand Tools – Just like a old leather tool belt or worn pair of double-knee Carhartts, there’s a certain romance to classic hand tools.

Scribing Made Simple – Learn and practice the basic techniques, then move up to the more difficult versions.

Best-Ever Framing Hammers – The prices might scare off some, but for a professional who swings a hammer every day, here are two smart choices.

Cutting With a Handsaw – For small, quick jobs where a power saw wouldn’t make sense, you’ll need to know the proper use of this carpentry staple.