The Rise of Metal Roofing

Long-lasting, lightweight, and resistant to hail and fire, metal makes an ideal roof.

Synopsis: Metal roofing is growing more popular due to a widening range of styles available and longer service life. Contributing writer Scott Gibson delves into all the different options for metal roofing, from materials to installation details. The article includes explanations of rating standards for metal roofing, as well as descriptions and pricing for a variety of roofing products, from modular panels made to look like shakes, shingles, and tile to classic standing-seam or through-fastened panels.

Metal roofing has a long history in the U.S., but until 20 years ago it was a bit player in residential construction, with just a 3.6% share of the reroofing market. That number has roughly quadrupled since then, according to an industry trade group.

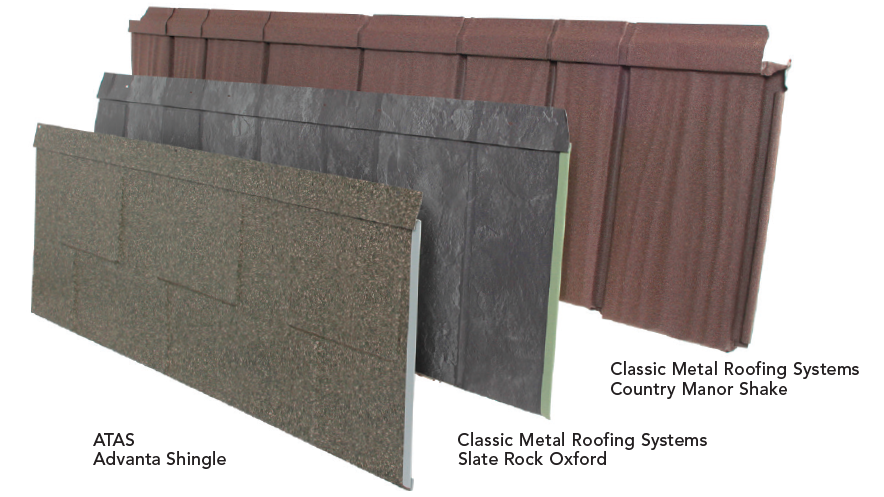

What happened? Metal roofing is now available in a range of styles—from standing seam to a variety of stamped metal shingles that look like slate, clay tile, and even asphalt. Paint and stone coatings are more sophisticated and durable, giving metal roofing a long service life while appealing to homeowners with a variety of aesthetic preferences.

The industry is also working harder to win over consumers who once thought that metal roofing was too hot, too heavy, noisy, or prone to rust, says Dick Bus, president of ATAS International and head of the Metal Roofing Alliance. “Those myths are gone, and people want to reroof with something that has some permanence to it,” he said. Metal roofing may never catch up to asphalt in the residential arena simply because of sticker shock. A standing-seam or metal-tile roof can be two or three times the initial cost of asphalt. But its longevity, recyclability, high fire resistance, and low maintenance has increased its acceptance.

Select a base metal

Steel and aluminum are the two most common and least expensive metals used for residential roofing. “On about 80% of all homes, either metal will work just fine,” says Todd Miller, president of Isaiah Industries, a manufacturer of a wide range of metal roofing products. “On the other 20%, it tends to be driven by climate in that area.”

Steel’s weakness is its potential for rust. One way to prevent it is to galvanize it by adding a coat of zinc to the surface before painting. The amount of zinc is key. A G-100 coating (1 oz. of zinc per sq. ft.) makes a long-lasting substrate for roofing, says Ken Gieseke, vice president of marketing at McElroy Metal, a Louisiana-based manufacturer. Galvalume is another, and widely regarded as better, option. In this process, bare steel is coated with an alloy of zinc and aluminum (generically, this coating is referred to as an AL-Zn alloy) before it’s painted or clear-coated. The treatment is especially useful in harsh weather conditions. McElroy cites a side-by-side comparison in which Galvalume- coated panels were two to four times as durable as galvanized steel after 23 years of weather exposure.

Bus prefers aluminum as the base metal over steel (his company manufactures both types). In “aggressive” environments—along the coast or in regions with highly acidic rain—aluminum is less likely to corrode, and if the surface is scratched, the panel won’t rust. Aluminum is slightly more expensive—7% more than the steel roofing leaving his plant.

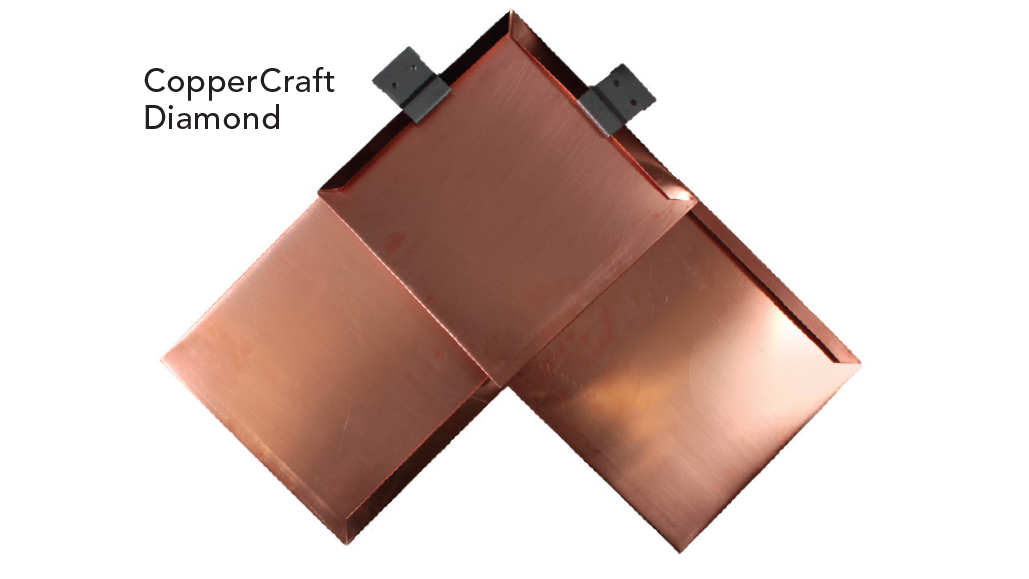

There are several other choices, all of them more expensive but also extremely durable. The best known is probably copper, with installed costs around $2000 per 100 sq. ft.

Zinc is another option with an extremely long service life—hundreds of years, according to Bus—but it’s never been as popular as copper in the U.S. Metal thickness ranges from about 0.014 in. to 0.05 in., depending on the profile and the type of metal. Manufacturers may use the metal’s gauge as a measurement—the lower the number, the thicker the material.

Testing for tough conditionsRoofing faces a variety of environmental challenges, but hail, high winds, and wildfire are certainly among the most difficult tests. For a rundown on the various rating standards for roofing, I turned to Stephen Knight, a professional engineer and engineering manager for McElroy Metal. Hail The standard test for resistance to hail damage is UL 2218. Steel balls in four different diameters are dropped from increasingly greater heights to simulate a hailstorm. A roofing sample fails if there is any surface tearing, splitting, or fracturing. Class 4 is the best rating, meaning the roof can withstand a 2-in. ball dropped from 20 ft. Wildfire Fire resistance is determined by UL 790. This includes three parts: application of an intermittent flame, a flame-spread test with a continuous flame, and a brand test, designed to test how a roof will react when a flaming ember or branch falls on it. Class A is the highest rating, “effective against severe fire test exposure.” High Winds There are several standard tests for wind. One major question to be answered is, at what wind pressure (not wind speed) will the roofing blow off? Results are described in wind uplift in pounds per square foot (psf). For example, when the specs list wind uplift as Class 90 (UL 580), this means that the roof will resist an uplift of 90 psf. Uplift pressures at any given wind speed are affected by a number of factors, including roof configuration, building height, and any openings in the building. The calculations are complex, but many manufacturers offer free engineering services to help with design. Tighter fastener spacing, narrower panel profiles, and using mechanically seamed panels all increase wind resistance. |

Select the finish coat

Treated steel and aluminum roofing substrates also get a topcoat. The most durable finish is polyvinylidene fluoride (PVDF); two of the most popular brands are Kynar 500 and Hylar 5000. These coatings resist fading and chalking much better than silicone-modified polyester (SMP) and polyester finishes. They also are more expensive. On a typical residential reroofing job, Kynar 500 may add a couple of hundred dollars to the cost, but SMP surfaces can begin to fade in less than 10 years.

“The technology is real,” Gieseke says of PVDF coatings. “It’s not a marketing gimmick. It’s really the best-performing system out there.”

Stone-coated steel is another finish option that some manufacturers offer. In a process that Boral says was developed in the 1950s, tiles start with Galvalume-protected steel, followed by an acrylic primer, then an acrylic resin binder to which the ceramic granules are bonded. The granules provide color and UV resistance.

While stone-coated roofing can be just as durable as any other type of metal roofing, Renee Ramey, the executive director of the Metal Roofing Alliance, suggests buyers discuss product specs with their installers. “The U.S. is experiencing an issue with subpar products being imported,” Ramey said. Dealing with MRA-member manufacturers is one way of avoiding a problem with substandard base metals and coatings that can shorten product life.

Both paint and stone-coated surfaces can be engineered so they reflect heat from the sun for cooler roofs and reduced cooling loads. The Cool Roof Rating Council describes a cool roof as one that reflects solar energy that hits the surface (solar reflectance) and radiates heat that is absorbed (thermal emittance). These properties are measured and described by a number between 0 and 1—the higher the number, the cooler the roof. In general, white and light-colored roofs will reflect more solar energy than black or charcoal-colored roofs, but even darker shades are now available with cool roof coatings. (For a product directory, check the Cool Roof Rating Council’s website.)

A variety of panel and tile choices

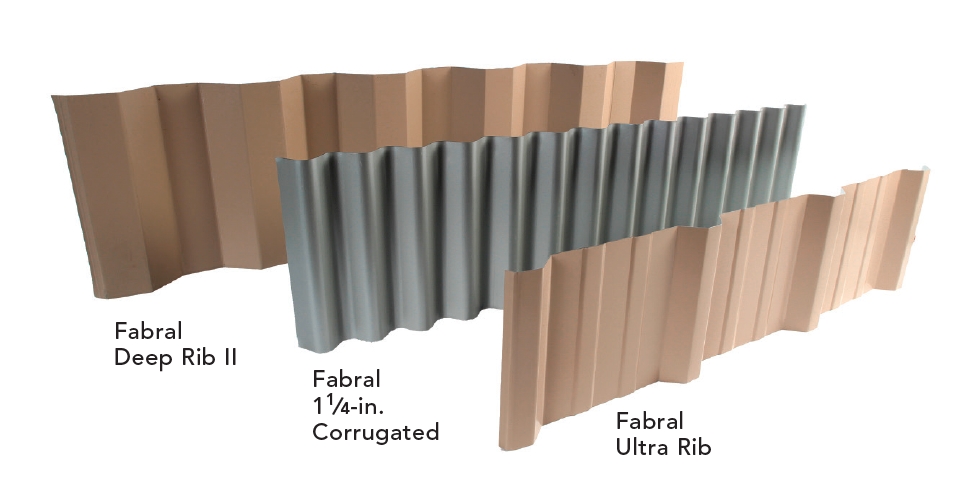

The most basic type of metal roofing is corrugated, galvanized panels roughly 3 ft. wide that run from eave to ridge. They are attached to the roof deck (or strapping) with screws that remain exposed when the roof is installed. Gaskets or washers between the screw head and the panel are designed to keep water out. These “through-fastened” roofing panels go up quickly, particularly on a simple gable roof.

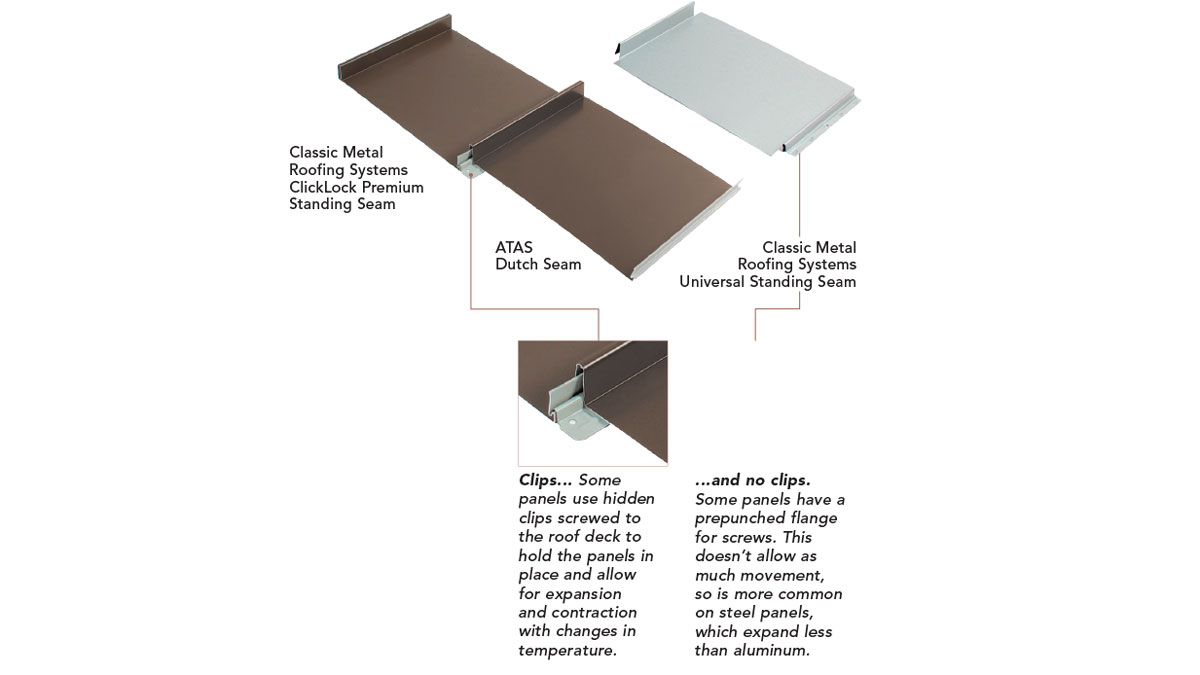

Standing-seam (or concealed fastener) roofing consists of a number of individual panels whose seams are joined either with an interlocking snap-lock profile or mechanically with a special crimping tool that installers take with them onto the roof. A crimped-seam roof is watertight on roofs with slopes as low as 1-in-12, but when the roof pitch increases to 3-in-12 or more, the snap-lock panels will keep water out about as well, Bus says. Wind resistance is another consideration.

Standing-seam panels are a step up in performance from through-fastened roofs, and also a step up in cost. Bus estimates that these concealed-fastener roofs typically cost between $8 and $9 per sq. ft. installed (remember that roof geometry, local labor rates, roofing profiles, and metal and finish choices all affect the price). Concealed-fastener roofing panels come in a wide range of profiles and colors.

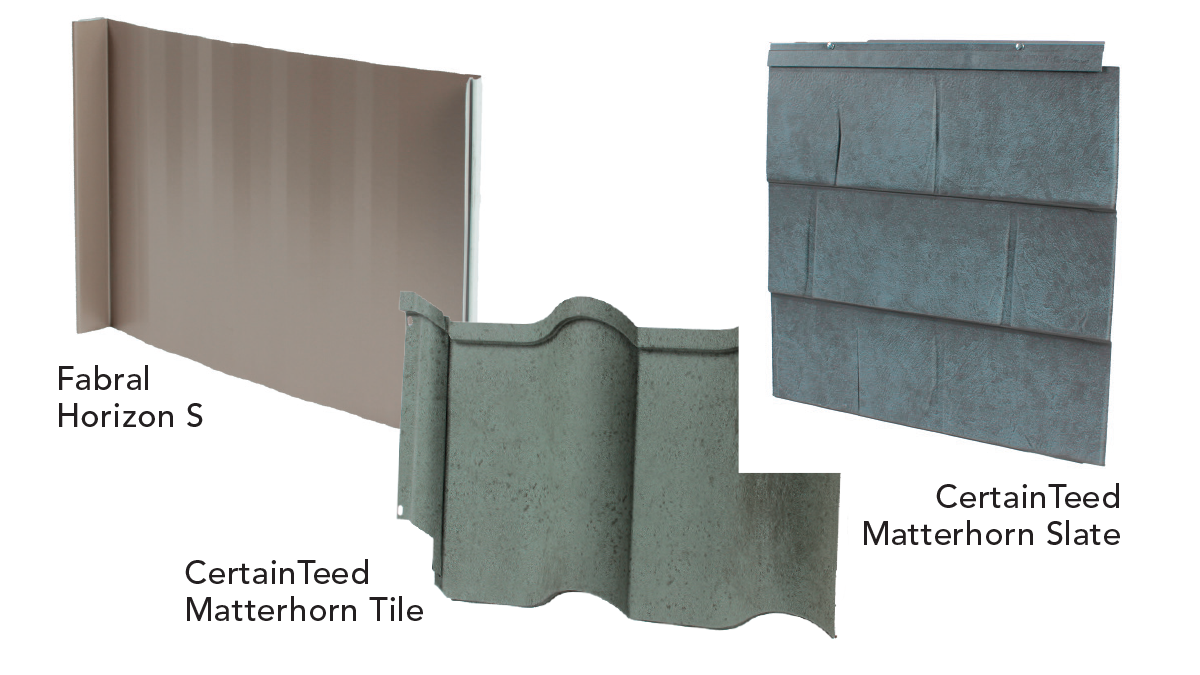

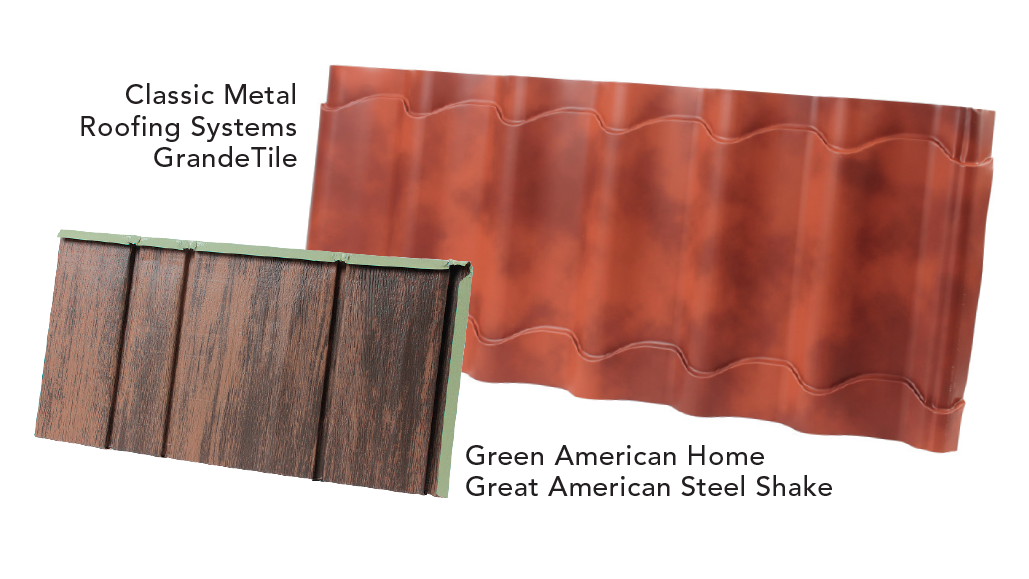

Finally, there are metal roofing shingles (also called “modular panels”), a diverse category that includes products manufactured to look like clay roofing tiles, wooden shakes, slate, and even asphalt. “Asphalt?” you might ask. This design is for homeowners who may not be able to get the OK from a homeowners’ association for a metal roof, or those who don’t want to rock the boat in a neighborhood full of asphalt roofs. Like other forms of metal roofing, shingles have a very long service life, and high hail and fire ratings.

What do designers prefer?

A metal roof is more expensive than asphalt, but the architects and designers I contacted prefer metal over asphalt and other roofing options. They cite a number of reasons: high recycled content, durability, and compatibility with rooftop solar panels. Typical of the responses was this from Ann Edminster, a California-based architect and green building consultant. “It’s extremely durable and of course usually has recycled content, and it’s infinitely recyclable,” she said. “The finishes on metal tend to be pretty benign and long lasting. It’s inherently reflective; metal just comes that way. The water coming off of it is clean because it’s not laden with volatile hydrocarbons and things like that.

“It’s really high in embodied carbon,” she adds, “but so is all roofing. And so it’s basically a contest between other attributes and metal. Metal stacks up better across all of those attributes.”

One final note from Miller: Don’t minimize the role of the installer. With skilled labor increasingly difficult to find, it’s more important than ever to find an installer who knows what he’s doing. Miller suggests contacting the manufacturer of the roofing you’ve selected and asking for the names of experienced installers in your area. “Proper installation is more important than product,” he says.

More about metal roofing:

Snap-Lock Standing-Seam Metal Roof Installation – Factory-made panels and flashing go together without specialty tools or subcontractors.

Is through-fastened metal roofing a good idea?

A Home Completely Wrapped in Metal Roofing and Siding – Bridger Steel’s standing seam metal roofing and siding creates clean lines for a modern exterior

From FineHomebuilding #289

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Fall Protection

Flashing Boot Repair

Shingle Ripper

View Comments

Fantastic article. It got me looking closely at zinc standing seam. Thanks, Scott!