Podcast 224: Botched Drywall, Bow-Roof Cabins, and a Baseboard Radiator Hater

The crew hears from listeners about tile showers, heat-pump water heaters, and Finex panels before taking questions on fixing bad drywall, making a bow-roof watertight, and revamping hydronic heat.

Follow the Fine Homebuilding Podcast on your favorite app. Subscribe now and don’t miss an episode:

|

|

Matt, Kiley, and Patrick hear from Doug about insulating tile showers in masonry structures. Taylor offers some praise for heat-pump water heaters. Mark discusses new methods for protecting foam foundation insulation. Jeremy’s truck stereo describes the FHB Podcast. Vanessa wants to know how to fix a home’s worth of bad drywall. Greg asks about building bow-roof cabins for a retreat center. Jay suggests another look at “T”-Studs. Tom asks if redoing his hydronic heating system will lead to divorce.

Listener Feedback:

Listener feedback #1

Doug Horgan in the DC area, writes, Hello podcasters, love the show and love seeing it on my app every Friday so I can make it jump ahead of the other podcasts!

Regarding tiling a shower next to an uninsulated masonry wall, we have “solved” that with foam-based tile backer board, which works as insulation and tile support in one.

The first time we needed this solution, the bath was in a condo and we were down to fractions of an inch to meet code, and we knew the clients would be uncomfortable if we didn’t get insulation into the assembly.

In CZ4, masonry walls (“mass walls”) insulated on the interior require R-13 to meet the prescriptive code, it’s 17 in CZ5 and 20 in CZ6, but goes down to 6 in CZ2, for what that’s worth. Obviously there are a number of ways to meet code besides using the prescriptive chart, and code is not necessarily the right number for comfort in a shower where you’re standing naked in front of the entire surface, so these numbers are just a starting point.

One trick you can do with Kerdi Board is to use fasteners on the first layer and then use thinset to attach the face layer, that way no fasteners go through the entire insulation layers to make cold spots, but I’m not sure how important that is.

Related links:

Taylor from Wisconsin writes, I recently made the switch from a 1994 electric water heater to the 50 gallon Rheem heat pump water heater. In the first month my utility bill dropped $50. It is a smart water heater and allows me to track usage as well as control the temperature from my phone. From July 27 – December 31 it used 258.26 kWh at $.09 a kWh, $23.24 total. I live in Wisconsin. It’s in a conditioned basement and is set to heat pump only mode. Family of 3 and have never had any issues with it.

Listener feedback #3

Mark writes, Howdy FHB Podcast Team, Back in episode 210, a listener asked about protecting rigid insulation at or below grade. We’re building a home using ICFs and have encountered the same issue. Looking around, I found a great looking option in a video from Hammer & Hand.

Scot talks about Finex panels at 1:20 and again at 3:20 in this video:

Finex panels are rated for ground contact with a limited lifetime warranty against delamination. I’d love to go this route but at about $160 US per 4’x8′ sheet of 1/4″, plus shipping from Canada, it’s a little too spendy. If you have the budget, check it out here: Advantages of Finex Fibercement Panels.

I’m leaning toward GroundBreaker from Nudo or alternatively, a more typical parge coat or surface bonding cement.

Trying to sort out all the details for our new home as an owner / builder has been a big challenge and several of your podcasts have been very helpful. Being off grid brings up a whole new set of constraints, particularly regarding power. For example, air sealing will be critical for reducing the heating requirements but running an ERV or HRV 24/7 is not a viable option due to our lack of winter sun to provide power. I plan to monitor indoor air quality (CO2) to control ventilation to minimize the required power. We want to use cord wood in a radiant system to provide more consistent temperatures than a typical wood stove, but again, power for the combustion blower in the boiler and the circulator pumps is a big deal. The key, in my mind, is to minimize boiler run time with heat storage and a tight, well-insulated building envelope. So far, I’ve gotten quite an education. It will be interesting to see how it works out.

Related links:

- How to Design an Off-Grid House

- Off-Grid in Canada: What We Did for Heat

- Twenty Below and Off the Grid

Jeremy writes, My 2017 Silverado radio ended up displaying an unfortunate, but humorous, title to the latest episode. Thought it share it with the FHB podcasters. Keep up the great episodes and racy titles!

Editor’s Projects:

None to speak of, but…

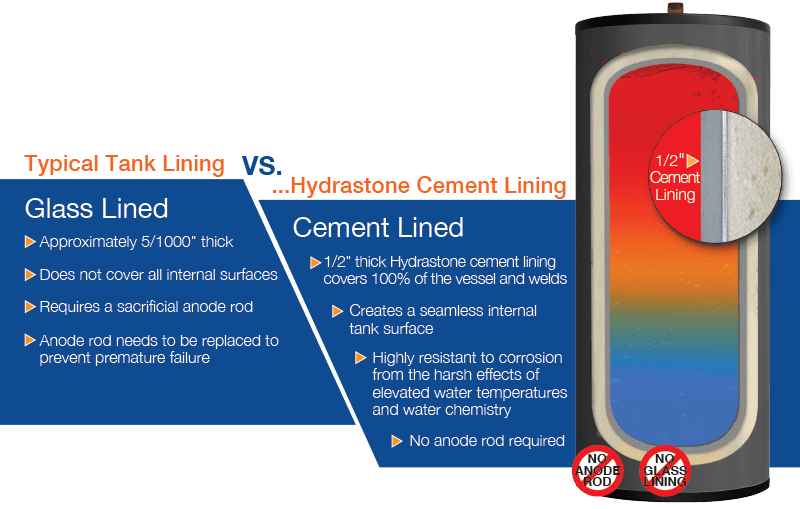

“T” asks: Change a water heater’s anode rod or not?

Mike Lombardi says: Not sure about other brand plastic water heaters. I have installed several Hubbell heat pump / hybrid electric water heaters. Hubbell has special tapping alloys & a “hydrastone” proprietary cement lining that is super resistant to corrosion; they guarantee long tank life without an anode. Anodes can be tricky & troublesome; sometimes they’ll produce offensive odors. Check out Hubbells website.

Electric water heaters generally outlast gas & oil fired tanks. The direct blast of fossil fueled combustion creates more stress, fatigue, and chemical reaction than a passive electric heating element.

Poor water quality coupled with lack of a maintenance routine will lead to poor performance & premature death. Your reader will benefit and save measurable amounts of energy with his routine.

Interestingly, water heater manufacturers know that a single anode rod in a residential unit will last about 6.5 years without any maintenance, hence the standard 6 year warranty. Ten or twelve year warranty models sometimes have a second anode, or, the manufactures invest the extra cost of the extended warrantee to offset the cost of a replacement tank, and, extended warranties are only good for one replacement tank…

Question 1: What’s the best way to fix cracked drywall seams on walls that are already painted?

Vanessa from Instagram writes, We renovated our entire house ourselves, including removing all of the drywall. When we put the drywall back up, we had a family friend give us advice on how to tape (he had done drywall for 20 years). He recommended fiberglass tape. After some time, the joints started cracking. Our neighbor is a project manager for another, large construction company. When we told him about the cracking, he sent over one of his drywall guys to help us fix it. Those guys had us sand the walls a little, then they just paper taped over the fiberglass tape. That was a whole other issue (their work involved tape bubbles, etc). We finally got everything all repaired and it all looked great (we’re talking months of work at this point). So, we primed it and painted. We now how cracks in the painted ceiling. We have an industrial sander that worked great for sanding the walls without paint, but now even the heaviest grit sander paper gets gunked up immediately.

It sounds like the best option now would be to dig out all of the fiberglass tape and paper tape, sand what we can to rough up the surface a bit and take down the edges, then use TSP to wipe it down before re-applying just the paper tape alone and feathering it out.

Any tips on how to patch drywall on level 5 finished walls that have already been painted. Using an industrial sander with rough grit sandpaper is just gumming up sandpaper immediately. Can I put drywall mud over painted surface? Any primer required to this? Thank you tons for any advice you can give!

Related links:

- What’s the Difference: Paper and Fiberglass Mesh Drywall Tape

- Invisible Drywall Seams

- Q&A: Taping New Drywall to Existing, Painted Drywall

Question 2: Can the podcast crew offer feedback about my construction details for a bow-roofed tiny house?

Greg from Cazadero, California writes, Hi Guys — Love your podcast – it’s been a really great way to expand my learning on building structures, moving from building boats to houses. There’s an old boatbuilder’s saying that house is just a leaky upside-down boat…

By the way, these will be heated with a small wood stove designed for bell-style tents, and be built upon a 12×16 freestanding deck platform with standard spacing of the deck boards (1/8”), so no, I will not be air-sealing or performing blower-door tests.

Thanks for any ideas, and thanks again for a great podcast, even if you never venture west of the Mississippi!

I got a few of the ribs up last night so we could figure out floor plan stuff – I’m better with mock-ups in person than on paper. Done by myself and some Yankee stubbornness and some help from Archimedes (I went to a small liberal arts college in Maryland, St. John’s College, and we studied him, including translating from the original Greek.).

My test bends with 29g corrugated didn’t go successfully, so I’m going to have to run the ribs horizontally instead of vertically, like a Quonset hut. Not enough time to get special-order bent panels. This means that the corrugations will act as lots of gutters, but in light rain the water may not have escape velocity and will surface cling to the underside of the panels. The siding for the walls will most likely be T1-11, so I’m thinking cut to the curve of the wall, then use the corrugated foam as a flashing? I’m planning on the corrugations sticking out past the roof at least 4”; I am ordering the panels in custom lengths so I can order longer if that feels better.

I’m thinking of going with a synthetic felt on these as well, since the corrugated will be producing some condensation, no doubt. So here’s my plan – on top of the ribs in teh picture (and they will be on 24” centers), 1/2” ACX, then synthetic felt, and then plastic corrugated spacers for the roofing to be attached to. The spacers are rigid plastic, unlike the foam ones, so there will be a roughly 1/8’ gap between the felt and the roofing, which should provide enough of a gap for a rain screen, or do you think I should shim it out further?

I’ll overlap the roofing and use a bead of silicone on the more horizontal panels.

Thanks again, and love the podcast – it’s my go-to on the way through the woods when there’s no reception.

Related links:

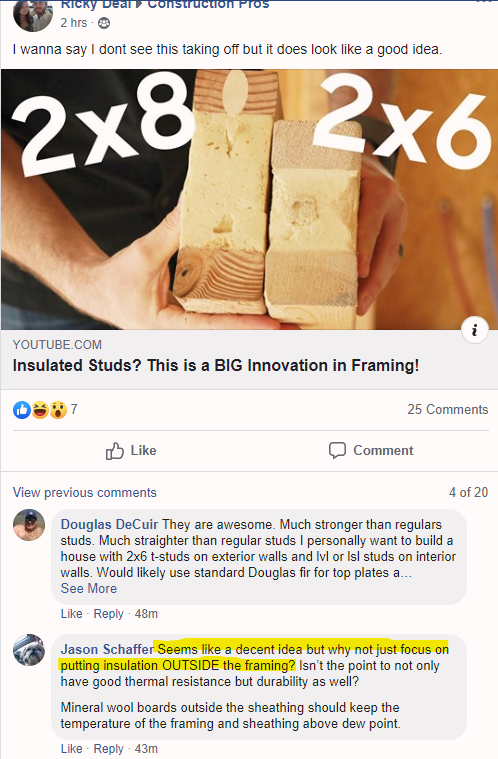

Question 3: Is continuous external insulation a better way to stop thermal bridging than insulated studs?

Instead of trying to debate if TSUDs are a good idea at all (has Patrick officially lost that argument at this point by the way? Please confirm….)

What if the question is this: Are they worth doing vs. just focusing on adding more external insulation?

My initial thoughts:

1) Both add a certain level of complexity via non-traditional building techniques. This would probably be crew specific but arguably a wash?

2) External insulation is inherently likely a better approach as it reduces risk to the framing from condensation and thermal cycling.

3) If we focus just on cost, we should be able to compare the R value from a TSUD wall vs. a traditional wall assembly with enough added external foam to match the TSUD. My guess is the external foam wins but that’s just a hunch.

4) If someone started cranking these out for near the cost of traditional 2×6 and 2×8, do they start to make more sense?

5) If the production scale was big enough, could these be produced for even less than traditional lumber since they could be made from smaller boards?

6) Assuming production scales and costs do drop significantly, would Patrick ever be willing to admit they might actually be a cool idea?

Thanks for the great podcast, magazine and website!

Related links:

Question 3: What are the pros and cons of replacing baseboard heat with radiant floor heat?

Tom from South Salem, NY writes, I’m about 15 miles from your offices (my neighbors back yard line is Wilton, CT). My wife and I share a 2000 square foot 1984 deck house/split level on 4 acres, the lower floor of which is half-buried in a hill overlooking our streams and pond. We have a separate 1200 square foot garage with in-law quarters, which also contains my workshop (I’ also a Fine Woodworking and Fine Gardening subscriber). We have a cat, and two young children, in order of importance.

The house is 2×4 construction, cathedral ceilings with batt insulation and a vented cedar roof. Half of the basement is below grade (1/2 the sq. ft. not height), all on slab, the slab ends up 4’ above grade where it comes out of the hill. The attached picture should help.

The house has 3-zone hot water baseboard heating (two zones upstairs, one down), 2 through-wall A/C units I can’t wait to get rid of, and 3 large Haiku fans on the 2nd floor.

1) 1/2 of the 1st level floor is exposed (slab), and the other 1/2 relatively easy to get to (snap-lock plastic flooring from Belgium, I think Aqua-step [for the kids]). Have a plumber I trust, and thinking about installing Warmboard R or it’s ilk on the slab, getting rid of the baseboards. Pros/cons?

2) 1/2 of the 2nd level floor UNDERSIDE (joist bays) is exposed, and the other 1/2 is a dumpster away. Assuming I can get the ceiling out without getting divorced, install staple up Onix under the whole top floor? Pros/cons?

The eventual flooring over the warm board will be tile and the afore-mentioned pvc (basement), upstairs the Onix will be under 3/4 ply subfloor, oak strips and granite (granite will have some decoupler under it). Is it worth the time, effort, and marital discord to just do all this, all at once, or attempt to “stage” it, doing the exposed area now, waiting to open up the rest of the ceiling/floor until later? I’ll have a plumber and drywall/painting crew, everything else is on me. All kidding aside I just want my house to be comfortable for my family (right now room to room it can be a 10º variance) and I fucking hate baseboard heaters.

Thank you for your time. Your on-air validation would go a long way to clearing this with the Missus. House exterior (lower deck is 2’ above the slab)

Related links:

End Note:

Kate from Montpelier, VT writes: I had to chuckle when I read the tip on p.14 of Fine Homebuilding March 2020 issue, #289, for building a plans holder from a piece of PVC pipe and some fittings. This story linked below hit the news in our town a month ago when a bomb squad was called in after someone found one of these on the roadside. Upon further investigation it was determined it held the registration papers for a trailer.

- Fine Homebuilding – March 2020 issue

- Road-Ready Construction Documents

- Suspicious object draws bomb squad examination

If you have any questions you would like us to dig into for a future show, shoot an email our way: [email protected].

If we use your question we’ll send you a FHB Podcast sticker!

#KeepCraftAlive

#KeepCraftAlive

KeepCraftAlive hats help celebrate the value of true craftsmanship–plus 50% of all proceeds from every hat sold go to the #KeepCraftAlive Scholarship Fund, supported by Fine Homebuilding and SkillsUSA.

Buy a #KeepCraftAlive hat or t-shirt

This episode is brought to you by Huber Engineered Woods, makers of AdvanTech and ZIP System products.

The Prove Tour product experience is coming to a lumber yard near you. Huber Engineered Woods fleet of traveling hands-on product demonstrations is hitting the road soon for lumberyard events across the country. Try ZIP System liquid flash, Zip System stretch tape and AdvanTech subfloor adhesive in an immersive product experience. For event details, check out the stories and highlights on @huberwood on Instagram profile each week or ask your local Huber rep about a local Prove It Tour near you.

Fine Homebuilding podcast listeners can now get 20% off anything in the Taunton store, including the Code Check series. These sturdy, spiral bound reference books will help you navigate the International Residential Code, The National Electric Code and the Universal Plumbing Code. Use the discount code FHBPODCAST to take advantage of this special offer.

We hope you will take advantage of a great offer for our podcast listeners: A special 20% off the discounted rate to subscribe to the Fine Homebuilding print magazine. That link goes to finehomebuilding.com/podoffer.

The show is driven by our listeners, so please subscribe and rate us on iTunes or Google Play, and if you have any questions you would like us to dig into for a future show, shoot an email our way: [email protected]. Also, be sure to follow Justin Fink and Fine Homebuilding on Instagram, and “like” the magazine on Facebook. Note that you can watch the show above, or on YouTube at the Fine Homebuilding YouTube Channel.

The Fine Homebuilding Podcast embodies Fine Homebuilding magazine’s commitment to the preservation of craftsmanship and the advancement of home performance in residential construction. The show is an informal but vigorous conversation about the techniques and principles that allow listeners to master their design and building challenges.

Other related links

-

- All FHB podcast show notes: FineHomebuilding.com/podcast.

- #KeepCraftAlive T-shirts and hats support scholarships for building trades students. So order some gear at KeepCraftAlive.org.

- The direct link to the online store is here.