A Case for Double-Stud Walls

Straightforward construction, common materials, and low embodied carbon are just some of the benefits of this superinsulated assembly.

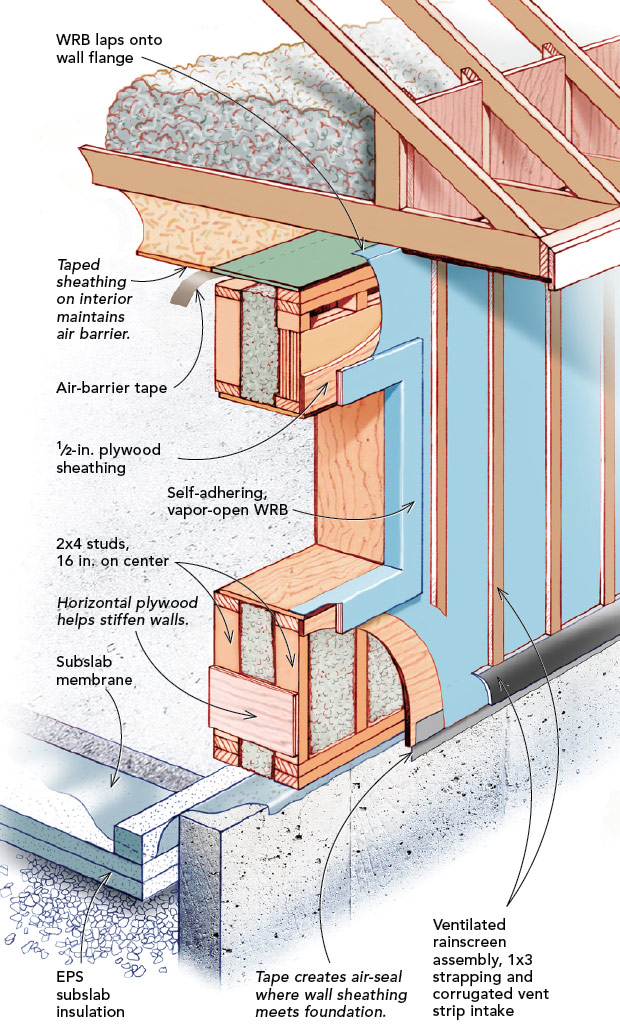

Synopsis: High-performance builder Dan Kolbert’s ideal wall is a double-stud approach filled with dense-pack cellulose insulation. In this article, he uses photographs and a detailed illustration to showcase how his team builds the vapor-open double-stud wall assembly, beginning with the exterior wall framing all the way to the ridge and then turning to the interior walls. He includes a sidebar about modeled risks of cold sheathing in double-stud assemblies—a much-talked-about but rarely seen phenomenon.

The ideal wall is debated constantly among conscientious builders, and unsurprisingly, opinions vary. Since my company is focused mostly on renovations, and we rarely build more than one new house per year, I have a lot of time to rethink my wall sections between each build. In the end, I keep coming back to the method we’ve used since we built our first high-performance home more than a decade ago—double-stud walls filled with dense-pack cellulose insulation. This double-stud wall approach not only uses an insulation you can feel good about, but it’s relatively affordable, easy to build, and can dry in both directions.

Even the best-performing wall design will only succeed if it’s buildable. The more complex water management, air-sealing, and other details become, the more likely you’ll fail.

There’s nothing in a double-stud wall that a competent carpenter doesn’t already know how to do. We make our walls about 12 in. thick, for an R-value of about R-44, with a full 5 in. of thermal break between the two 3-1⁄2-in.-thick stud walls. By contrast, other methods of building high-performance, thermally broken walls, like installing rigid foam or other continuous exterior insulation, require additional detailing to get the flashing and air barrier right, and to provide adequate nailing for trim and siding. Plus, exterior insulation has to be protected from rodents and insects. With double-stud walls, all of the insulation is inboard of the sheathing.

Sequencing the build

There are different ways to build a double-stud wall, but my preference is to keep it as much like building a standard house as possible. This means the exterior walls are built first and are the load-bearing portion of the assembly. This is one area that’s actually easier than single-wall construction—the exterior walls are 2×4 rather than 2×6, so they’re faster to build and easier lift into place. With 2×4 exterior walls, keep in mind that you may need an engineer to sign off on your wall design, especially if the walls are taller than normal or you want to space studs 24 in. on center, and that you will need to size your headers to fit on 2×4 jacks.

We typically get the entire exterior of the house framed all the way to the ridge, then come back and build our interior walls. Since they’re not load bearing, there are no structural headers in the interior walls. You can align the interior wall plates against the exterior walls and transfer window and door locations, and then frame the interior walls short enough so that you can lift them into place under the ceiling joists or strapping. Another benefit of double-stud walls is that you can lay out the exterior walls specifically for sheathing and the interiors specifically for drywall.

Some builders have tried to use 2x3s for the interior half of double-stud walls. It may seem like a good idea, but it’s not worth the trouble. The quality of 2×3 lumber is typically awful, and even if the pieces are straight when you get them, they tend to warp and twist after installation.

If your house is slab-on-grade, the double walls may not be sitting on much. We typically have an 8-in. foundation wall, then 4 in. of perimeter foam, then the slab. With a 12-in. wall thickness, our interior wall is sitting on top of foam. To deal with this, we cut scraps of 2x or strips of scrap plywood to 12-in. lengths and use them to connect the two walls at the base to hold the interior wall rigid.

There’s a lot to like about cellulose

I’m always looking for ways to simplify the construction process, and I think a building with one insulation material is better than one with multiple. Cellulose allows us to use the same material everywhere except at the foundation and slab. It is an affordable material, has very low embodied energy, can be repaired, and works very well as a buffer when vapor drive spikes. It can hold and redistribute moisture, releasing it to the dry side, in ways that foam, fiberglass, or mineral wool can’t. Finally, using wood rather than foam or other petroleum-based materials is key to reducing the carbon footprint of new buildings, and cellulose is wood. (On that note, it’s important to make sure that the cellulose your installer uses is a borate-treated product for resistance to fire, insects, and rot.)

While our climate is overwhelmingly heating dominated, with vapor drive to the exterior for much of the year, our summers are getting hotter and more humid. This increases my interest in wall assemblies that allow drying in both directions—another reason why skinning a house in rigid-foam insulation makes me more nervous than the cold-sheathing risk of a double-stud wall packed with cellulose (see “Modeled risks remain unproven in our builds,” below).

It is critical to note that all of the houses our firm builds include a rainscreen of some sort, which varies depending on the siding. We typically use a three-dimensional mesh product like Benjamin Obdyke’s HomeSlicker for shingle siding, and 1x3s or plywood rips for clapboard siding. This allows any moisture from vapor drive in either direction to drain or evaporate instead of getting trapped and rotting out the siding, sheathing, or both. I think it is very dangerous to not include a rainscreen in any superinsulated wall assembly.

|

|

A skilled insulation installer is a must

Once the house is framed, things progress pretty much as on any other house. Unlike with other thermally broken methods, window and door installation and flashing is the same as on a “standard” assembly. The drainage plane is in line with the window flanges, making lapping of materials simple. And our clients love the deep interior window stools these thick walls create.

Since we’re not production builders and all of our projects are custom homes, it’s hard to develop meaningful cost comparisons. The exterior walls are less expensive than most high-performance assemblies, since 2×4 walls use less material and less labor. The interior wall adds cost, but the walls are easy to lay out and fast to build, and electricians and plumbers love that they can do their rough-in with far less drilling. The insulation will cost more than in a code-level wall, but not necessarily more than a home with continuous exterior rigid foam and cavity insulation. On top of all that, you have to weigh the savings in the homeowners’ heating bills, and in the durability of the home itself.

Double-stud walls do require highly skilled installers to get the right density of the cellulose insulation. We break up walls by blocking between bays with plywood or netting so the installers don’t have to dense-pack huge volumes.

A common question is whether you can use batts instead of dense-pack cellulose. We’re cautious of that approach. I think the reason that moisture-profile modeling of double-stud walls misses the mark is that it doesn’t take into account the moisture-buffering capacity of cellulose. No other readily available insulation can mimic this phenomenon of absorption and redistribution. Dense-pack cellulose is fairly common in New England, less so in other parts of the country.

There are other blown-in products available, such as mineral wool and fiberglass. Mineral wool may have sufficient density to mitigate convective loops or moisture transport, but I have less faith in blown-in fiberglass. And batt insulation of any type is extremely difficult to install well enough for safety. Finally, while I am undecided on the need for a “smart” vapor retarder with cellulose, with any other product I would definitely recommend a variable-permeance membrane like SIGA’s Majrex, CertainTeed’s MemBrain, or Pro Clima’s Intello.

Modeled risks remain unproven in our builds

The main argument that I hear against dense-packed double-stud walls is the concern about “cold sheathing” that comes up when the assemblies are computer modeled. I consider this the Yeti of building science—it is much discussed, yet rarely seen.

We returned to our first double-stud house several years ago to replace a window with a door. The window was on a wall that was not only north-facing, but faced the water as well. If there was anywhere on the house where we should have seen moisture problems, it was here. Nevertheless, when we cut into the wall we saw no signs of condensation or leaking on the sheathing.

On several more recent houses, we have buried OmniSense wireless monitors in the walls and ceilings to measure temperature, relative humidity, dew point, and wood moisture content. Nothing in the data indicates the kind of problems that the modeling suggests is unavoidable, at least in our area (climate zone 6). Even so, if these walls are even theoretically dangerous, why do we continue with them? Simply put, I think they are better walls on almost every front.

More about double-stud walls

Is There a Chance For Condensation in Double-Stud Walls?

Energy-Smart Details – Lstiburek’s Ideal Double-Stud Wall

Windows and Doors in Double-Stud Walls

—Dan Kolbert is a builder and remodeler in Portland, Maine. Photos by Scott Gibson.

For more photos and details, click the View PDF button below.

From Fine Homebuilding #291

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Stabila Classic Level Set

Tajima Chalk Rite Chalk Line

Guardian Fall Protection Pee Vee