Fire-Resistant Drywall

These panels look the same as regular drywall, but special additives and glass fibers make them more effective at containing fire.

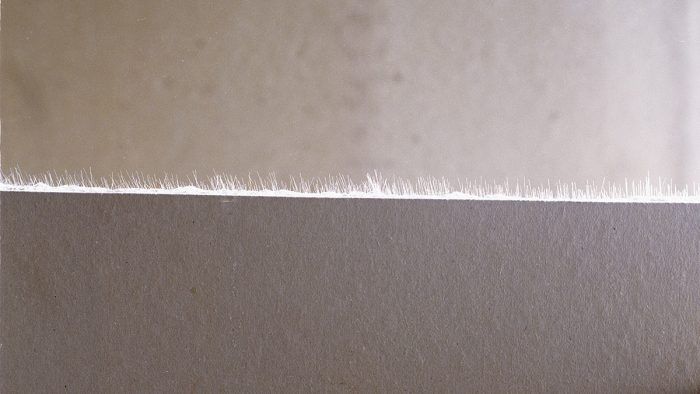

As a dense, noncombustible, mineral-based material, drywall in all its forms is a better fire barrier and a more efficient sound absorber than lighter materials, such as plywood. Even better, fire-resistant drywall has a gypsum core with special additives and glass fibers that are particularly effective in containing fire. This drywall is a little harder to cut than regular drywall, because the gypsum core is tougher.

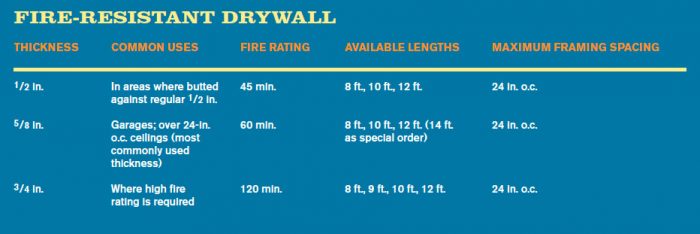

On the surface, these panels look the same as regular drywall, except for a stamp indicating that they are fire resistant. The term fire resistance means the ability of a constructed assembly (a wall or a ceiling covered with drywall) to contain a fire. The fire-resistance rating for each thickness of drywall is measured in intervals of time: 45 minutes for 1/2-in. fire-resistant drywall, 60 minutes for 5/8-in. panels, and 120 minutes for 3/4-in. panels. The panels can be layered to increase the fire rating.

| WORK SMART: When installing fire-resistant drywall on garage ceilings, use 5/8-in. panels. The joists are usually spaced 24 in. o.c., and—in the varying temperature and humidity levels common in most garages—5/8-in. drywall isn’t as likely to sag as 1/2-in. |

One-half-in. fire-resistant drywall Many building codes specify fire-resistant drywall for attached garages, furnace or utility rooms, and ceilings and walls separating dwelling units in apartment and condominium complexes. The two most commonly used fire-resistant panels are 1/2 in. and 5/8 in. One-half-in. panels are convenient when you need to cover only part of a wall or ceiling with fire-resistant drywall and finish the rest with regular 1/2-in. panels (the most common standard thickness). For example, a garage ceiling might be finished with two types of drywall. Typically, only the first 5 ft. of the ceiling adjacent to a wall needs to be fire resistant. Using the same thicknesses of fire-resistant and regular drywall allows you to make a smooth transition at the joint. If you use different thicknesses (say, 5/8-in. fire resistant and 1/2-in. regular), you’ll create a seam that’s difficult to hide during the taping process.

Five-eighth-in. fire-resistant drywall For fire resistance, 5/8-in. panels are the most commonly used size. They have the one-hour fire rating that many building codes require. Because most garage-ceiling joists are 24 in. o.c., 5/8-in. panels work best because they are approved for 24-in. spacing. Although manufacturers approve 1/2-in. panels for joists 24 in. o.c., they are more likely to sag, especially in a garage that is exposed to extremes in temperature and humidity. Because of the extra thickness and stronger core, 5/8-in. fire-resistant drywall stands up better to denting and other types of abuse than 1/2-in. drywall does. Because garages often suffer a lot of abuse from car doors, bikes, and tools, I prefer to cover the entire surface with 5/8-in. drywall.

Three-quarter-in. fire-resistant drywall This type of drywall has a two-hour fire rating or a four-hour rating when the layers are doubled. It is used where a high fire rating is a must, such as to separate apartments or to divide offices from a garage or factory. The extra thickness and fire rating mean fewer layers, cutting down on the cost of materials and labor.

| WORK SMART: Any time you’re using specialty drywall (moisture/mold- or fire-resistant, for instance) in conjunction with regular drywall, use matching thicknesses so you’re guaranteed a smooth transition at the joint. Inconspicuous seams save a lot of trouble at the finishing stage. |