Drywall Corner Beads

You'll need beads for all outside corners, some inside corners, and occasionally to cover the edge of a panel.

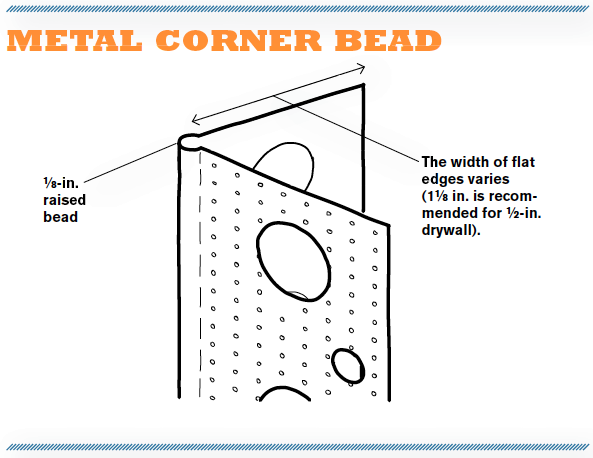

Outside corner beads

Whether on a wall or on a soffit, outside corners must be covered with corner bead. The material protects the surface and has a slightly raised beaded edge, which keeps the corner straight and acts as a screed while taping.

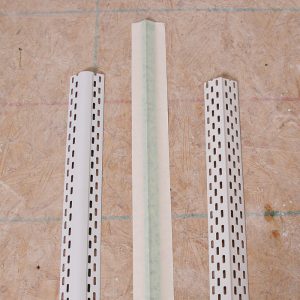

It wasn’t too long ago that square-edged metal corner bead was the most commonly used corner bead, and it may still be today, but the other options really are worth looking into. Today, you have your choice of metal, vinyl, plastic covered with paper, or metal covered with paper. Some types are available in 100-ft. rolls. Bullnose beads are also available in a variety of sizes and have become very popular because they offer an elegant look and are just as easy to install as regular bead.

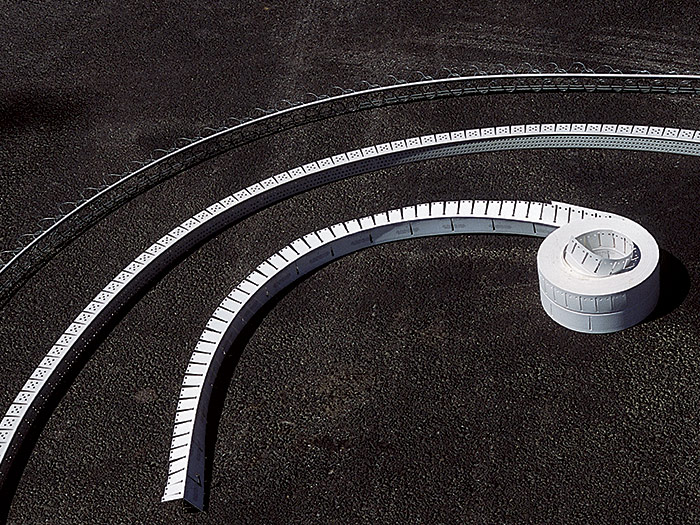

Archway bead For years, I used metal corner bead to finish the edges of archways. The only way to install it was to snip the bead at 1-in. intervals and push each piece into place along the curve of the arch. This method worked, but it cannot be compared to the simplicity and quality you get with new products designed specifically for archways. There are three basic types of flexible corner bead made for arches:

- Flexible wire bead has a plastic beaded edge and is nailed in place.

- Vinyl bead has a pre-snipped edge that is glued and stapled in place.

- Composite bead has a PVC core and a paper surface and is embedded in joint compound.

| WORK SMART: For off-angle inside corners, use either an adjustable bead that comes in stick form or, for longer runs, roll form. These newer styles of beads do a great job of keeping off-angle corners straight. |

The PVC material comes in rolls up to 100 ft. long and is now available in stick form with a wire reinforced edge. The wire and vinyl beads come in lengths of up to 10 ft. and the composite bead comes in lengths of up to 100 ft. Vinyl bullnose corner bead, which is flexible, is available to match the outside and inside corner bullnose beads. If you are using bullnose corner bead on your 90-degree corners, then you will most likely want bullnose on the archways. The vinyl bead companies make archway beads in all the bullnose radii. There are even bullnose beads made for off-angle inside and outside corners (135-degree corners only).

Inside corner beads

On most inside corners, I use paper tape embedded in joint compound, which is then covered with compound and feathered to a smooth edge. This method works great for inside corners that are around 90 degrees.

When I first saw a 90-degree inside corner bead I really couldn’t see why anybody would use it. I am a professional and I get great results with paper tape so I wouldn’t spend the money on a bead for a 90-degree inside corner. But after using the different types of bead I can see why they would be used:

- You don’t have to coat the very inside edge with compound. Therefore, both sides of the corner can be coated at once—as opposed to waiting for one edge to dry and then coating the other.

- When sanding you can sand the inside edge clean and straight, because you don’t have to leave any compound in the corner.

- All this adds up to a great-looking inside corner, especially for the less experienced taper.

- The end result is a very strong and straight inside corner.

If an inside corner is much wider than 90 degrees, a specialized product is a must for achieving the straight lines that define these corners. Fortunately, there are a number of products that can handle these off angles. Some work on both inside and outside corners; others are more specialized and designed for application on specific-angle corners. For off-angle inside corners, there is even a product that has a rubber center groove, which flexes if the structure moves slightly, greatly reducing costly callbacks. Inside corner beads are also available in bullnose styles to match bullnose outside corners. These products cost more than regular paper tape and compound, but you easily make up the extra cost in time saved and improved quality.

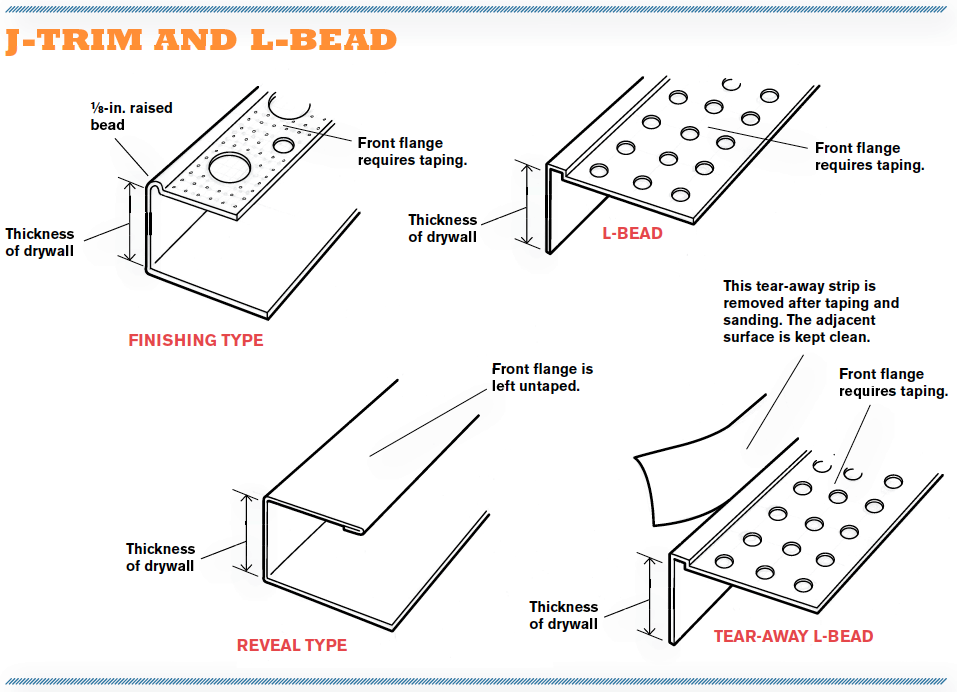

Trim beads

Metal, plastic, and paper-covered metal J-trims are caps used to cover the edges of drywall panels. Typically, they are applied against a shower stall, a window jamb, or a brick wall; around an opening that is left untrimmed; or on the exposed end of a panel. J-trim is available in different thicknesses to fit different sizes of drywall. It can be installed before the panel is hung or after the panel is loosely attached. It is held in place by driving a nail or screw through the face of the drywall and through the longer back flange of the J-trim. Some types need to be finished with joint compound, whereas others do not require any finishing at all (see the drawing below).

An L-bead finishes the edges of drywall that butt up against something, such as a suspended ceiling, a window, or a paneled wall. The drywall is cut so that the short edge of the L-bead can be inserted between the drywall and the abutting material. The exposed edge of the bead is then finished with joint compound. Many of these L-beads have a removable strip that protects the abutting surface from compound and some can be left on to protect the surface from paint. Trim beads are available in lengths of up to 12 ft. long and for 1/2-in.- and 5/8-in.-thick drywall. I prefer L-beads over J-beads in most applications, as L-beads are easier to install—especially on longer runs—because they are attached after the drywall.

Expansion joints

Expansion joints, which are made of metal or vinyl, are installed between drywall panels. They are not covered with joint compound, as other typical drywall joints are, but they can be filled with a flexible caulk. Expansion joints are designed to compensate for the expansion and contraction of building materials and for the normal settling of a building, so that drywall seams don’t become cracked or ridged. They are used when there is a large expanse of ceiling or wall. On ceilings, they run from wall to wall; on walls, they run from ceiling to floor. In high stairway walls, they are installed from wall to wall.