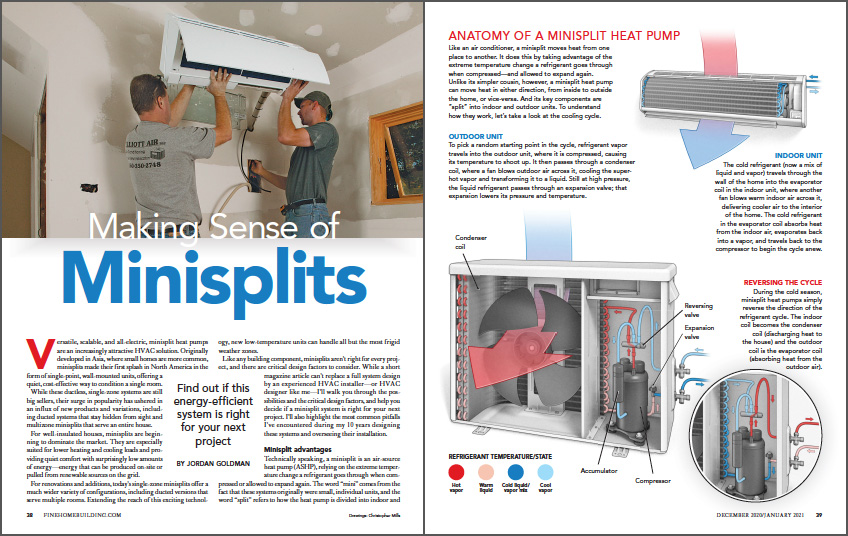

Making Sense of Minisplits

Learn how a minisplit system works and the various options for single-zone and multizone systems.

Synopsis: Minisplits offer an all-electric heating and cooling solution with a range of design options. HVAC designer Jordan Goldman explains how a minisplit system works and the various options for single-zone and multizone systems, how to size a minisplit system and the hazards of doing so incorrectly, and other considerations to make when deciding on or installing a minisplit system.

Versatile, scalable, and all-electric, minisplit heat pumps are an increasingly attractive HVAC solution. Originally developed in Asia, where small homes are more common, minisplits made their first splash in North America in the form of single-point, wall-mounted units, offering a quiet, cost- effective way to condition a single room.

While these ductless, single-zone systems are still big sellers, their surge in popularity has ushered in an influx of new products and variations, including ducted systems that stay hidden from sight and multizone minisplits that serve an entire house.

For well-insulated houses, minisplits are beginning to dominate the market. They are especially suited for lower heating and cooling loads and providing quiet comfort with surprisingly low amounts of energy—energy that can be produced on-site or pulled from renewable sources on the grid.

For renovations and additions, today’s single-zone minisplits offer a much wider variety of configurations, including ducted versions that serve multiple rooms. Extending the reach of this exciting technology, new low-temperature units can handle all but the most frigid weather zones.

Like any building component, minisplits aren’t right for every project, and there are critical design factors to consider. While a short magazine article can’t replace a full system design by an experienced HVAC installer—or HVAC designer like me—I’ll walk you through the possibilities and the critical design factors, and help you decide if a minisplit system is right for your next project. I’ll also highlight the most common pitfalls I’ve encountered during my 10 years designing these systems and overseeing their installation.

Minisplit advantages

Technically speaking, a minisplit is an air-source heat pump (ASHP), relying on the extreme temperature change a refrigerant goes through when compressed or allowed to expand again. The word “mini” comes from the fact that these systems originally were small, individual units, and the word “split” refers to how the heat pump is divided into indoor and outdoor units, with one fan and one coil in each and refrigerant lines running between.

Deployed properly, minisplits are a very quiet, very efficient source of heating and cooling. They are also increasingly versatile, thanks to a proliferation of new products and solutions led by major overseas manufacturers like Mitsubishi, Fujitsu, Daikin, and LG, and followed by traditional U.S. players Lennox, Carrier, and others.

As they have been from the beginning, single-point ductless minisplits are hard to beat for all-year comfort in single-room additions and renovations—simpler and less costly to install than tying into an existing HVAC system, and more energy-efficient than stand-alone solutions for heating and cooling.

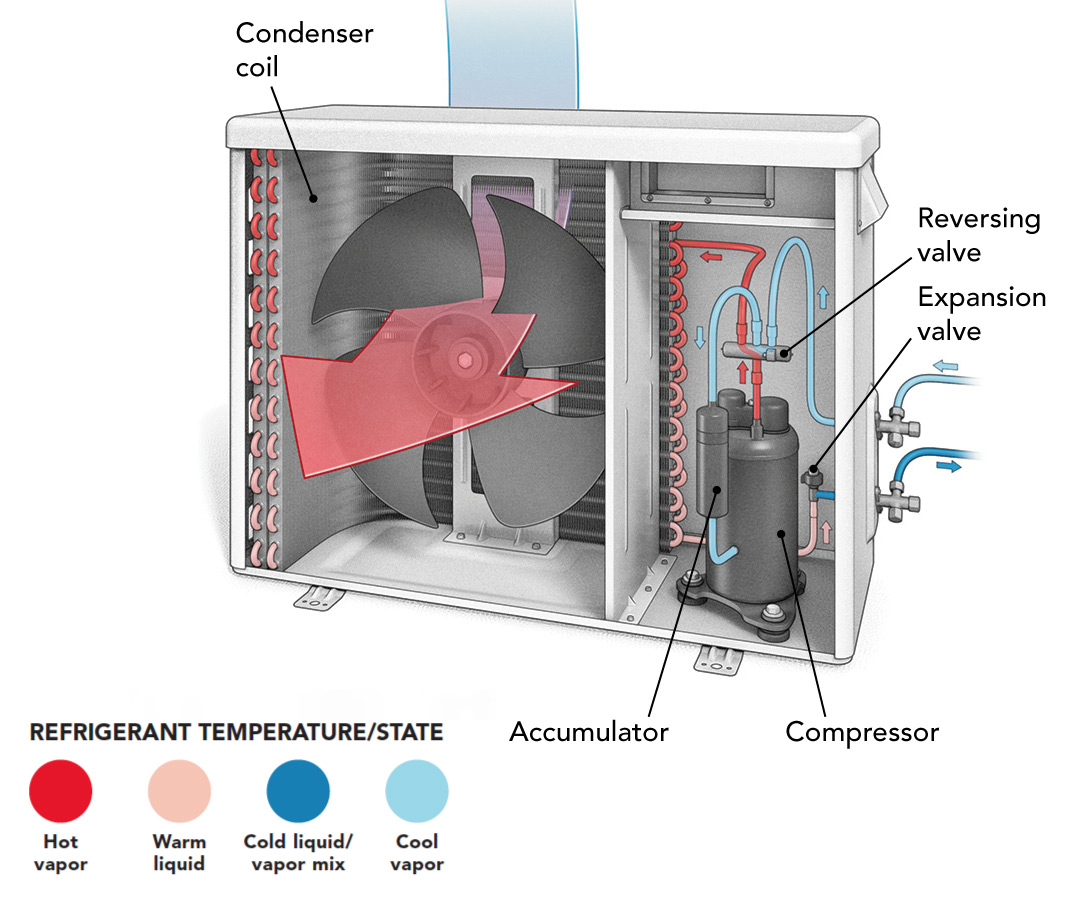

Anatomy of a Minisplit Heat Pump

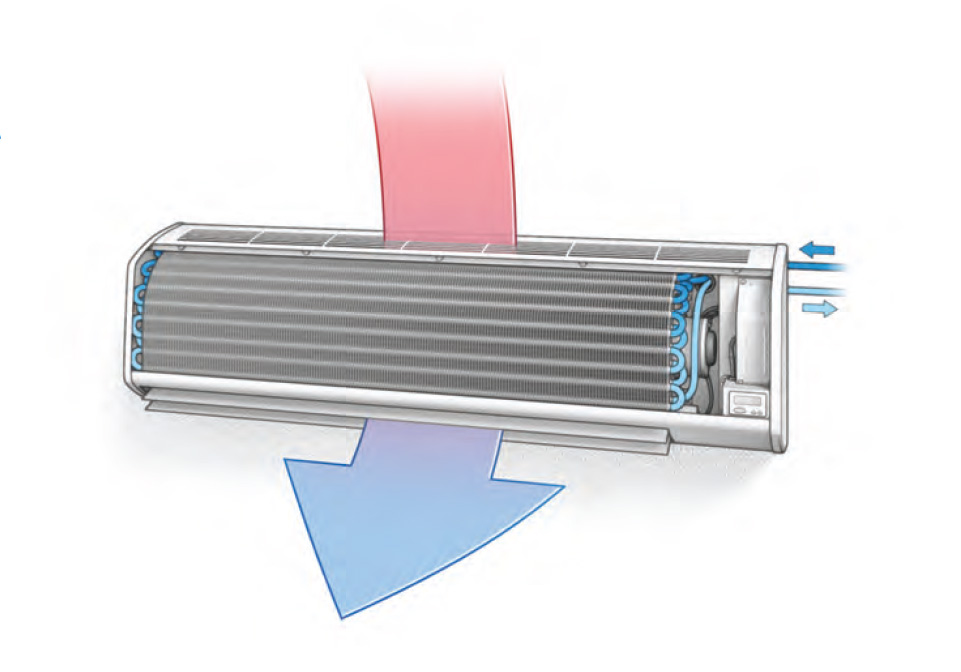

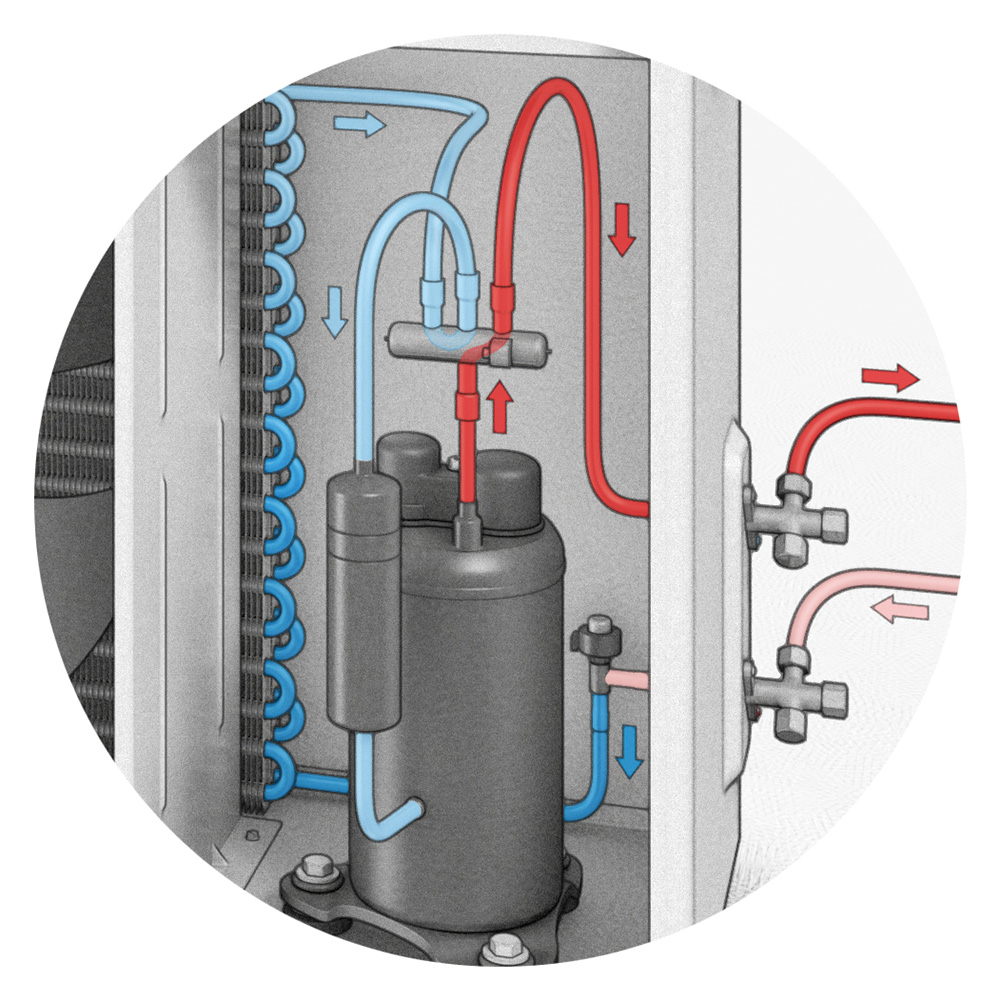

Like an air conditioner, a minisplit moves heat from one place to another. It does this by taking advantage of the extreme temperature change a refrigerant goes through when compressed—and allowed to expand again. Unlike its simpler cousin, however, a minisplit heat pump can move heat in either direction, from inside to outside the home, or vice-versa. And its key components are “split” into indoor and outdoor units. To understand how they work, let’s take a look at the cooling cycle.

Indoor unit

The cold refrigerant (now a mix of liquid and vapor) travels through the wall of the home into the evaporator coil in the indoor unit, where another fan blows warm indoor air across it, delivering cooler air to the interior of the home. The cold refrigerant in the evaporator coil absorbs heat from the indoor air, evaporates back into a vapor, and travels back to the compressor to begin the cycle anew.

The cold refrigerant (now a mix of liquid and vapor) travels through the wall of the home into the evaporator coil in the indoor unit, where another fan blows warm indoor air across it, delivering cooler air to the interior of the home. The cold refrigerant in the evaporator coil absorbs heat from the indoor air, evaporates back into a vapor, and travels back to the compressor to begin the cycle anew.

Outdoor unit

To pick a random starting point in the cycle, refrigerant vapor travels into the outdoor unit, where it is compressed, causing its temperature to shoot up. It then passes through a condenser coil, where a fan blows outdoor air across it, cooling the superhot vapor and transforming it to a liquid. Still at high pressure, the liquid refrigerant passes through an expansion valve; that expansion lowers its pressure and temperature.

Reversing the cycle

During the cold season, minisplit heat pumps simply reverse the direction of the refrigerant cycle. The indoor coil becomes the condenser coil (discharging heat to the house) and the outdoor coil is the evaporator coil (absorbing heat from the outdoor air).

And while ductless minisplits are visible in the room they serve, new models and mounting positions make them less obtrusive. Compared to a noisy window-mounted AC unit that steals the view, for example, a quiet, out-of-the way minisplit is a no-brainer.

Minisplits are available today in both single- and multizone configurations, with larger outdoor units able to support up to eight indoor ones, and ducted indoor units that hide in mechanical rooms, above dropped ceilings, in kneewall spaces, and more.

They are especially well-suited to well-insulated homes, with indoor units available down to 6000 Btu per hr. and outdoor units down to 9000 Btu per hr., helping HVAC designers avoid oversizing, a primary cause of poor operating efficiency and shortened equipment life.

Regardless of which minisplit system you choose, an all-electric HVAC system can draw its energy from on-site sources or the grid, which is increasingly powered by renewables, contributing to the health of the planet and making the home ready for a carbon-neutral future.

Using electricity also reduces the demand on natural-gas infrastructure, which is aged and leaky in many parts of the country— particularly in New England where I work. If natural gas isn’t available and heating fuel would otherwise be propane or oil, an electric-based heating system eliminates the need for fuel delivery and on-site storage. Forgoing fossil fuels also makes a home safer and more healthful by eliminating the possibility of gas leaks or carbon-monoxide poisoning.

Reality checks, and reasons to say no

Minisplits have a few disadvantages and downsides, and they are interrelated, combining to make or break the minisplit decision. The big three are the price of electricity, the severity of the winter, and the quality of the building envelope.

In many parts of the country, electricity is more expensive than natural gas. So if you switch from a gas heating system to an electric one (even an efficient minisplit), the operating costs may go up. Propane and oil, on the other hand, tend to be expensive fuels by comparison, shifting the advantage to the minisplit. Also, for a growing group of people, the environmental advantages of an all-electric HVAC system tend to outweigh a small disadvantage in present operating costs.

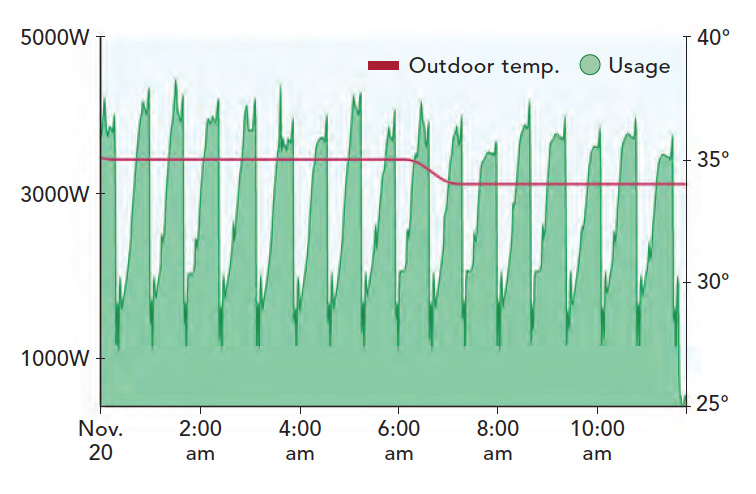

Since heat pumps extract heat from outside air in winter, a minisplit’s heating capacity decreases as outdoor temperature drops. In fact, each unit has a minimum operating temperature at which it will shut off to protect the compressor—typically around or below 0°F.

Along with capacity, the operating efficiency of a minisplit also decreases as outdoor air gets colder, driving up energy usage. This creates a double-whammy of lowest efficiency when the heating demand is highest. That said, minisplit technology has improved greatly, and new low-ambient-temperature models can handle temperatures below -10°F at a respectable efficiency and only a small drop-off in overall capacity. Very hot summers are not a problem for minisplits, just as they aren’t for large central air-conditioning units.

Heating equipment is just half of the thermal-comfort equation. A high-performance building envelope will insulate homeowners from periods of low operating efficiency or high electricity costs. In other words, if the building doesn’t need much energy for heating, system efficiency and fuel costs matter a lot less. Conversely, a poorly insulated house is often a deal breaker for minisplit systems, especially in cold climates.

Common configurations

To understand the many ways minisplits are deployed in today’s homes, it helps to think somewhat separately about the outdoor and indoor units. Let’s start outside, where one outdoor unit can serve one or more indoor zones.

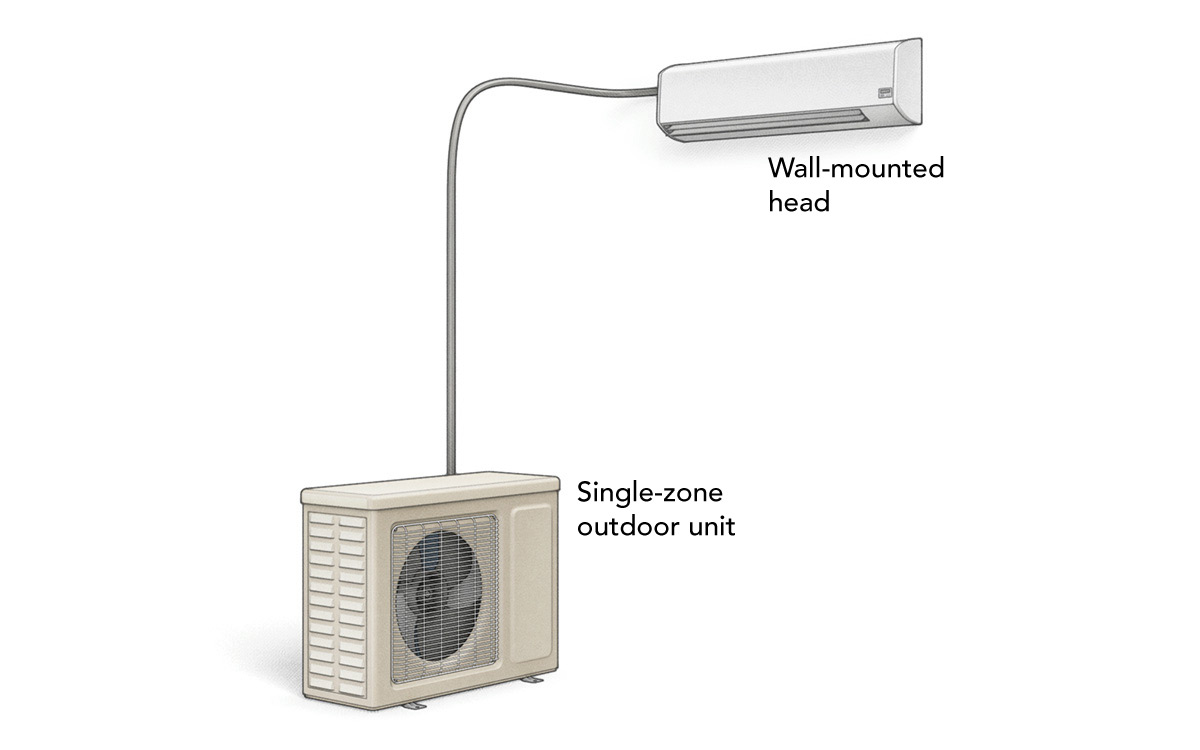

Single-zone minisplits have one outdoor unit connected to one indoor head, with one thermostat controlling a single thermostatic zone. These have two important advantages over multizone systems. First, single-zone systems modulate very well in partial-load conditions, giving them the highest operating efficiency, all other things being equal. Second, when multiple single-zone systems are used to heat and cool an entire house, each individual minisplit can be dialed in to the specific needs of its zone, be that a cool basement or a great room with a big array of sunny windows.

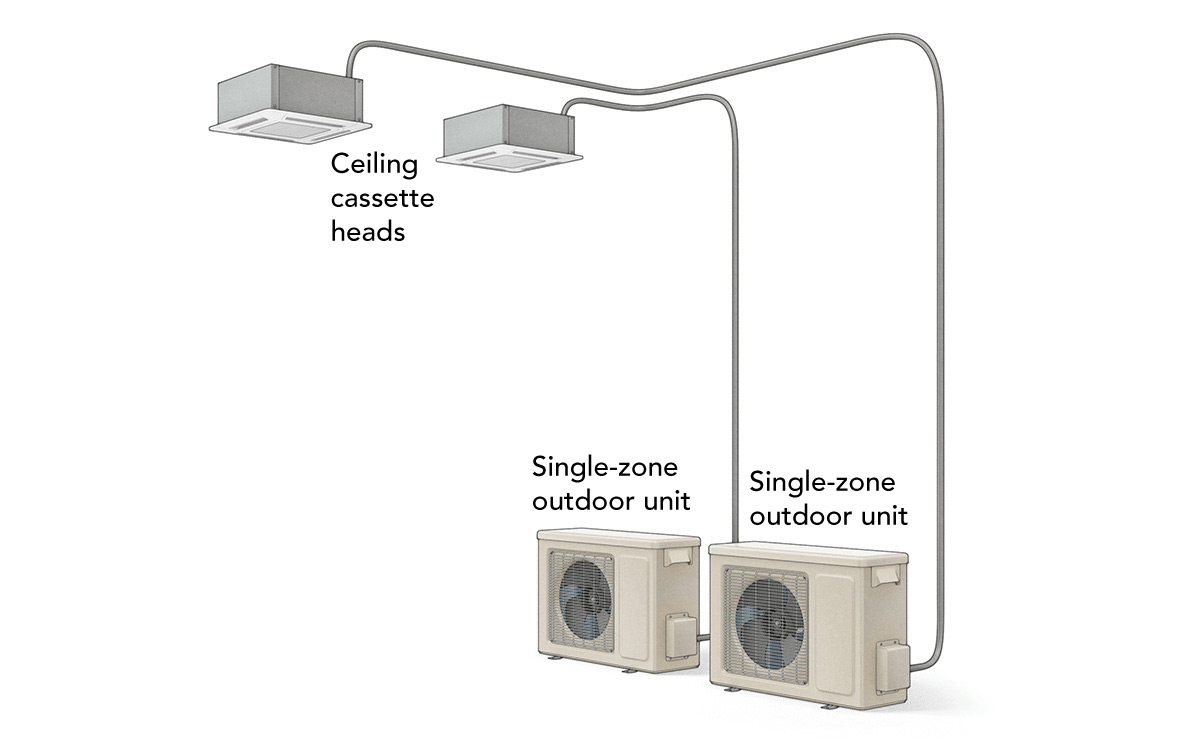

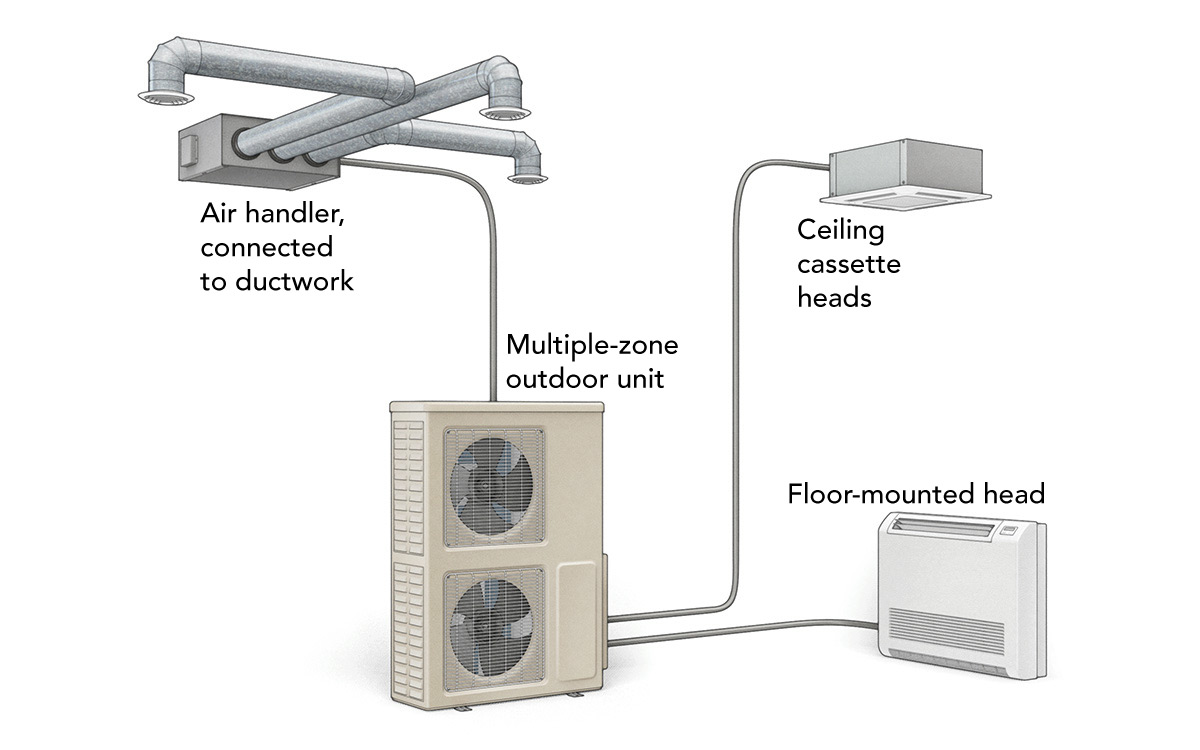

It’s hard to hide a “compressor farm” of outdoor units, however, so designers often turn to larger, multizone units, which can connect to multiple indoor units. Each indoor unit represents an individual thermostatic zone. The main downside here is a loss of efficiency, as the single outdoor unit tends to be oversize, and unable to modulate its output as well as multiple single-zone units would be.

On the indoor side, whether the minisplit is single- or multizone, there are both single-point ductless units and ducted systems that can supply multiple rooms in a single zone.

Ductless units serve a single room, so they work really well in an open floor plan or a single-room addition or renovation. The advantages are easy installation, compared to a ducted heating and cooling system; low comparative cost; and excellent energy efficiency.

The downside is aesthetics, since all ductless models are visible. That said, the indoor units are much more attractive than a window-mounted AC unit.

While most people think of a wall-mounted unit when they think of a ductless minisplit, today there are also attractive floor-mounted units that recall a traditional radiator, and can be recessed into cabinetry or the wall itself, if access is created for changing filters, etc. There are ceiling cassettes too, recessed into the ceiling, with grids delivering the conditioned air. In any case, it’s my experience that, while homeowners sometimes start out with a negative visceral reaction to ductless units, once the units are installed they fade into the background and people stop noticing them.

As their name suggests, ducted indoor units include a duct system attached to an air handler. The big advantages are the ability to serve multiple rooms with a single indoor unit, and the invisible infrastructure. The air handlers for ductless systems are available as “ceiling-concealed” units, typically installed above a dropped ceiling, and multi- position air handlers, comparable to the air handler in a conventional ducted HVAC system. The latter can be a good fit for replacing the air handler or furnace in an existing system, since they can provide the high static pressure needed to push air through a large network of ducts.

For air handlers placed above a ceiling, accommodations must be made for changing filters and someday replacing the entire unit. That’s why I like placing them in a mechanical room if possible.

Design starts with critical math

The first step of a minisplit design (or any HVAC design, for that matter) is calculating the peak heating and cooling loads the system will be able to handle while keeping the indoor temperature and humidity within a desired range. This “design day” is usually calculated at 99% and 1% of the yearly temperature range. In other words, for heating, that would be the outdoor temperature your location stays at or above for 99% of the hours of the year. For cooling, it’s the outdoor air temperature the environment exceeds during just 1% of the year.

Therefore, by design, there are likely to be a handful of hours each year when the outdoor temperature is more extreme than the design temperature. But if you designed a system for the coldest day on record, it would be way overbuilt, leading to all of the problems associated with oversizing (described below).

The desired indoor temperature range is the other big factor in equipment sizing. As a starting point, most codes require that 70°F (heating) and 75°F (cooling) are used for system-design calculations. But homeowners’ comfort expectations can vary, which can change the system design significantly.

The good news is that the major equipment manufacturers now offer online software that leads you through the math, calculating the heating/cooling output for any of their systems, given the design conditions specific to your project.

Even with a good design program to guide you, it’s helpful to understand the principles behind the numbers. Manual J is the common protocol for peak heating/cooling load calculations. When matching those up with a minisplit heat pump, it’s critical to look at its output during the specific outdoor conditions of your design day.

Both heating and cooling outputs are a function of outdoor air temperature, so if you simply look at the nominal capacity of the heat pump, you may end up with an undersize system.

On the flip side, oversize systems are a well-known cause of poor performance of all types of HVAC equipment. Oversize equipment will short-cycle (start and stop frequently) as it rapidly meets the home’s heating/cooling demand and then turns off. Short-cycling is analogous to driving in stop-and-go traffic: It leads to poor operating efficiency and decreased equipment life. It’s much better to have HVAC equipment running for longer periods of time at a lower output—analogous to highway driving at constant speed.

Additionally, an oversize system, running intermittently, will do an inferior job removing moisture from the interior during the summer. Like AC units, indoor minisplit units have integrated drains that carry condensation to the exterior or into plumbing. This works best when the system is operating at sufficiently long durations to run all of the indoor air over the coil.

Once you’ve calculated the peak heating/cooling loads and know the required system output, the next step is to determine the right number of zones for your project.

While zoning is very helpful for providing individual control for various areas of a house, it’s generally best to minimize zones where possible. Fewer zones means less indoor equipment to maintain, and also makes it easier to avoid equipment oversizing.

In most cases, a small addition or renovation is best served by a single- zone system. If you’re installing a system for an entire house, then different zones for different floors are helpful to counteract natural temperature stratification. Additionally, if part of the house has a heating/cooling load that is out of sync with the rest of the house—for example, a highly glazed west-facing room in a house that otherwise faces south—a separate zone will help provide even temperatures throughout the house.

3 Versatile HVAC Solutions

Minisplits can be deployed in a number of ways, from single-zone systems to multizone systems that connect to a variety of head units.

1. Single-zone systems are still the most popular

Perfect for additions and remodels, these simple, stand-alone minisplits have one outdoor unit and one indoor head unit mounted on a wall or floor or recessed in a ceiling.

2. Combine single-zone minisplits in a multiple-zone system

The most energy-efficient way to create a multizone system is to dedicate a separate minisplit to each zone, sizing each outdoor unit to its individual heating and cooling loads.

3. Serve multiple zones with one outdoor unit

Where numerous outdoor units would be hard to hide, designers often go with a single, larger, multizone unit. These are often connected to an air handler hidden in a ceiling or mechanical room, with ductwork running to multiple zones, but multizone outdoor units can also be connected to standard indoor heads.

As previously mentioned, the empirical data shows that multiple single-zone minisplits—with a separate outdoor unit for each indoor one—perform more efficiently than a single multizone minisplit connected to multiple indoor units. On the other hand, a multizone minisplit is likely to be more cost-effective than an array of single-zone systems. And depending on the property and the number of zones, you need to consider whether numerous outdoor units will be an eyesore.

No matter what sort of outdoor units are driving the indoor one, those indoor units can be ductless, ducted, or some combination of the two. Ductless units are less expensive than ducted units—plus you avoid the cost of ductwork—but in some cases a single ducted unit can replace multiple ductless ones, improving the cost comparison. In general, ductless units are a great option for large spaces, open floor plans, single-room additions and renovations, and situations where it’s not feasible to install ductwork. Ducted units, on the other hand, can heat and cool multiple rooms, improving performance and reducing maintenance by reducing the number of zones. And they provide a more aesthetically integrated solution by hiding all of the equipment.

Pitfalls to avoid

Having done this for a while, my firm has seen and made our fair share of mistakes. Whether you’re a homeowner, home builder, or HVAC professional, the following will help you design and install a minisplit system that’s safe and effective for many years to come.

I’ve already mentioned the hazards of oversizing minisplit systems, from poor operating efficiency and shortened equipment life to reduced dehumidification. Beyond getting the design day right, and calculating heating and cooling loads correctly, the most common trouble spot is unnecessarily complicated zoning.

Due to the connection rules for a given unit, a larger minisplit system might be necessary to serve the increased zoning, even if a smaller heat pump could meet the overall peak heating/cooling loads. So if the number of zones are leading to an oversize outdoor unit, it’s better to find a way to combine small areas into a single zone using a ducted system, or to use one-to-one minisplits to service one or all of the zones. Zone design might require tough conversations with clients, so it’s important to explain the long-term benefits of a properly sized system.

Even modest altitude can have a significant effect on design calculations, since the density of air is a determining factor in how much energy it can embody. I learned this the hard way when I had to redesign a project in Boulder, Colorado. When the local contractor asked if I had factored in the mile-high altitude, I was forced to admit that I hadn’t. At that altitude, a heat pump is about 20% less effective than it is at sea level.

Minisplit heat pumps come precharged with some refrigerant, but almost all will require more be added. Undercharged (or overcharged) systems will perform very poorly. The only way to determine exactly how much refrigerant to add is to measure the installed refrigerant lines, and the only time you can do this accurately is while they’re still exposed, so you have to remember to do it before the drywall goes up.

Another consideration is static pressure, which is important in ducted systems—the static pressure of an air-handling unit is a measure of the fan’s ability to overcome pressure drop in the duct system. Pressure drop in a run of ductwork is the sum total of a number of factors: duct length, fittings and junctions, filters (especially dirty ones), balancing dampers, grilles, and more.

An air handler that produces lower static pressure will consume less energy, but if the pressure is inadequate for the duct system it’s attached to, you’ll get reduced airflow and reduced heating/ cooling capacity. For example, some ceiling-concealed ducted units are only available with low static pressure, meaning that they can only be connected to a small, simple duct system.

Here are a few more critical tips for the air handlers in ducted systems. Because they typically have the ability to generate a range of static-pressure levels, they need to be set to the proper default setting for the system design. Also, be sure the system is set to sense temperature at the thermostat, not the air handler, as the latter is almost always isolated from the living space.

Filter replacement and regular equipment maintenance are critical to getting the most out of your system and maximizing its life. This is especially important on ducted systems. If filters are difficult to access, for example, they won’t be replaced, getting extremely dirty over time, slowing airflow, and reducing heating and cooling capacity, not to mention worsening the indoor-air quality.

Also, if snow builds up and covers the outdoor unit, it will lose its ability to function. The same thing happens if melting frost can’t drain away, and the outdoor coil ices up. For both of these reasons, it’s important to raise the outdoor unit off of the ground in cold climates.

The bottom line

Minisplit heat pumps are versatile, effective heating and cooling systems, with lots of applications, including high-performance houses, additions, and renovations. Knowing the key design factors and common pitfalls will ensure a successful installation, delivering low operating costs and excellent comfort for the occupants.

– Jordan Goldman is the engineering principal at ZeroEnergy Design, a Boston-based architecture and engineering firm that specializes in low-energy, high-performance houses.

Photos by Patrick McCombe.

From Fine Homebuilding #296

To view the entire article, please click the View PDF button below.

View Comments

One thing not mentioned in the article is 'maintenance' of minisplits! This is often overlooked and not a big issue with one or two indoor units. However if there are multiple indoor units maintenance becomes a nightmare. Every indoor unit must be deep cleaned annually or mold and mildew can present a serious problem. There are many videos on how to do this and after looking at a couple we installed a Geothermal System!