The Slow Evolution of Paint

As manufacturers tinker with chemistry to improve durability, ease of application, and hide, the distinction between water- and oil-based paints is blurred—for the better.

Synopsis: The basic building blocks of paint haven’t changed in decades, but residential paint has undergone some changes. Contributing writer Scott Gibson researches what’s new in paint, describing the increased durability of low-VOC products and the improvements made to water-based paints. The article includes interior and exterior paint recommendations from professionals, and a list of new hybrid water-based alkyd paints and specialty problem-solving paints.

Responding to wartime shortages of basic raw materials, Sherwin-Williams managed to produce the nation’s first water-based house paint in 1941. Consumers snapped up 10 million gallons of Kem-Tone in the first three years of production, according to an account by the American Chemical Society. Industry chemists ever since have been incrementally improving their water-based paints to make them easier to apply, last a long time, and cover in one or two coats.

A ban on lead in residential paint in 1978 and government limits on volatile organic compounds (VOCs) in paint have been instrumental in pushing oil-based paints toward extinction, and also have forced manufacturers to develop paint that’s less toxic while retaining the best characteristics of solvent-based coatings. The result is a wide range of choices for consumers who will now pay more for top-quality paint than they used to, but also get more in return.

The basic building blocks of paint haven’t changed in decades. House paint (what the industry calls architectural coatings) has four main ingredients—the carrier (now mostly water), resins, pigments, and additives. Manufacturers continue to tinker with these constituent parts and how they are combined to improve overall performance and meet consumer needs, such as stain or scuff resistance. The industry continues to invest in waterborne technology while oil and alkyd paints get less and less attention. (Most commercially available “oil-based” paints are made with alkyd resin and not oil, but the same drawbacks apply).

This is not news—the industry was saying essentially the same thing 10 years ago. So the question is, have residential paints gotten any better since then?

“Let’s say they’re different,” says Bob Welch, the technical director of the Master Painters Institute, which develops testing standards for the industry. “They are better in some respects. There have been great advances in lowering VOC content, which is a good thing for the environment. The durability of the early low-VOC products wasn’t as good as it is now. The application properties weren’t as good. They are much improved since then.”

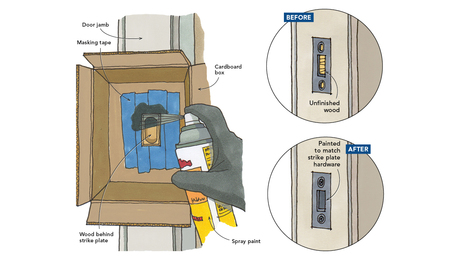

Rules of thumb you won’t find on a labelConsumers who like to do their homework before buying paint will face some challenges. There is more information on a 99-cent can of pinto beans than there is on a $75 can of exterior paint, and even if you’re a knowledgeable chemist, the information that is printed there won’t be of much help. Still, when shopping for paint, these general rules of thumb seem to apply: 1— Once you pick the brand of paint you like, price is a good overall indication of relative quality from that manufacturer. 2— Water-based paints are getting better at replicating some of the most desirable qualities of alkyd paints—faster curing times and better surface hardness—while offering the environmental advantages of acrylic resins. 3— Manufacturers have introduced more products that fit niche needs, such as fast-drying paint that allows windows and doors to be closed shortly after they are painted, or exterior paint that sheds dirt when rinsed with water. 4— How paint is applied—meaning the brush that’s used, the technique, and the prep work—is just as important as the quality of paint in getting good results. |

A hybrid approach

Lower VOC limits make it so paint smells better, is safer to be around, and contributes less to smog. But the transition to waterborne coatings has been a major challenge to manufacturers. When Kem-Tone was introduced nearly 80 years ago, professional painters preferred the oil-based paints they were used to, and waterborne paints were not as forgiving to apply.

“It was a big change,” says Steve Revnew, senior vice president for marketing and product innovation at Sherwin-Williams. “There wasn’t a whole heck of a lot of durability. The technology just wasn’t as advanced as it is today. It just continues to progress.”

The U.S. Department of Environmental Protection now limits VOC content to 250 g per liter for flat paint and 380 g per liter for other sheens. Some regional agencies have much more stringent requirements. In Southern California, the South Coast Air Quality Management District sets a cap of 50 g per liter and manages a list of “super compliant” paints with less than 10 g of VOCs per liter for extravigilant shoppers. A number of manufacturers offer zero-VOC paints.

The rules are gradually pushing alkyd paints to the sidelines. Although some jurisdictions allow high-VOC paints to be sold if they come in small containers, alkyd paints are getting harder to find. Oil-based primers, Welch says, are not even available in some parts of the country.

“Oil-based paint is the buggy whip of paint,” says John Lahey III, president of Fine Paints of Europe, a Vermont-based company that imports a line of Dutch paints. Many painters and consumers, however, fondly remember some of the performance characteristics of oil-based paints, and manufacturers have tried to duplicate these characteristics in waterborne paints while simultaneously taking advantage of benefits that acrylics offer.

“What do oil-based paints do better than acrylics?” Lahey asks. “They look better; they level better. And you can get purer, deeper, richer colors. But latex coatings do a lot of things better than oils. They’re more bendable and flexible. They’re more forgiving. They’re easier to use. They also hold their color better, longer than alkyd. That’s why all these contractors and homeowners are wanting to use acrylics but they want the look of the oil.”

This best-of-both-worlds approach has led a number of companies to the hybrid paint model. These are waterborne paints that contain small amounts of alkyds. They are sold as “waterborne alkyds” or “water-based alkyds.” Manufacturers say they level better than all-acrylics, are harder, and have deeper colors. They also have low VOCs and can be thinned with water (meaning they clean up with soap and water rather than solvents). These include such brands as Emerald from Sherwin-Williams, Advance from Benjamin Moore, Speedhide from PPG, and Eco from Lahey’s company.

Lahey says these hybrids are typically used on trim, where hardness and some sheen are often desired, although there are versions for painting exterior walls. Hybrid paints, Lahey says, take some getting used to. If they are being brushed on, most of them should be applied with a synthetic brush, but follow manufacturer recommendations on the can. The hybrid paints also have a shorter open time than conventional alkyds, which means they can only be brushed for so long before they start to set. “It doesn’t have the same forgiveness on the application side,” Lahey says.

While waterborne alkyds have been a fairly recent breakthrough, even these low-VOC hybrids might be threatened in the future. Darin Laird, PPG’s senior group technical leader in architectural coatings, says that if the VOC limit drops to 25 g per liter, as he’s heard it might, hybrids could very well be history.

Why cost often equals quality

Pigments and resins are the keys to some of the most important characteristics of paint—how well the paint hides what’s underneath, for example, and the durability of the paint film. Manufacturers don’t say much about the proprietary resins they use, but titanium dioxide is an industry standard and an important hiding pigment. It’s also relatively expensive, so it’s less likely to show up on the label of a cheap paint.

In general, higher-cost resins and pigments mean higher retail costs. Conversely, when you want to make a less expensive paint, you start by taking stuff out of the mix that costs too much. The first thing to go, Welch explains, is the hiding pigment, which in white paint is titanium dioxide. That means the paint costs less but it also loses hiding power. So, for example, it might take more coats of paint to hide a color that had been applied previously. Then you trim back the resin content—the binder that holds everything together. Now, Welch adds, the paint is less expensive still, but the paint film isn’t going to have the same integrity that a more expensive paint would provide.

“Basically, you reduce the solids of the paint; the amount of paint that’s left when it dries,” Welch says. “You reduce the expensive components, which are the resin and the hiding pigment, and you also reduce the total solids in the can. They all have a cumulative effect.”

With that in mind, one approach to choosing paint is selecting the manufacturer you like (Sherwin-Williams, say, or Benjamin Moore) and then specifying the most expensive option the company offers in a particular category—the priciest exterior wall paint, for example, or the most expensive trim paint. Price comparison may not be the most useful approach when trying to choose between different manufacturers, but within one company’s offerings, price is probably the most reliable measure of quality a consumer is going to get.

These days, top-quality U.S. paints are running $80 and up per gallon, but niche products can cost much more than that. Fine Paints of Europe sells some paint at $155 for a 2.5-liter container (what Lahey calls a “Eurogallon”). It should cover as well as a U.S. gallon, he says, but the price is still going to shock some would-be buyers right out the door. Maybe so, Lahey says, but that’s because the binders and the product-specific pigments are expensive. Unlike most paint companies, his doesn’t use Universal Tinting Colorants , or UTCs, but rather tints that are specific to a certain paint.

“When you approach it that way, you get an entirely different level of coating,” he says. “You get better tinting accuracy; better coverage when tinting dark or tricky colors. It’s the quality of the paint, but also the quality of the pigment used in the paint that elevates the game.”

He adds that one thing to keep in mind is that the cost of paint is probably going to be a small part of the total cost of a professional painting contractor’s price. If the painter bids the job at $2000 and it’s going to take two gallons of paint, does it really matter if the paint costs $100 and not $25?

Painters’ picksWe have been covering the evolution of paint at Fine Homebuilding for as long as we’ve been making the magazine. Unfortunately, we are not set up to test paint, so we contacted a few professional painters to ask for their recommendations. Jason Eidsness, who can be found online as @XC_Painter, works in the Pacific Northwest and prefers products from Benjamin Moore, Sherwin-Williams, and a few less common brands. “It’s not my main wall choice,” Eidness writes, “but let’s get Scuff-X checked off as a great product.” He uses the specialty Benjamin Moore paint for high-traffic areas. But Eidness’s go-to for walls is Benjamin Moore’s Regal Select in eggshell. “You can’t go wrong with this paint with how easy it is to use,” he writes. “It has great flow with a brush or roller, and good coverage.” He recommends Benjamin Moore’s Aura in eggshell for “slick feel, cleanability, color retention, and coverage.” Though Aura is marketed as a one-coat paint, Eidness still recommends two coats. For production jobs, he recommends Ultra Spec 500. “However, currently I am using Sherwin-Williams ProMar 200 HP in eggshell for walls and bathroom ceilings,” writes Eidsness. “It’s their middle-range product, available in three sheens only. It’s working pretty well. Brushability and coverage is good. The eggshell sheen is a little shiny compared to others, but it does look nice and feel nice.” Eidsness says that Benjamin Moore’s Advance in satin is one of the best trim paints. “It flows so well off the brush, with a long open time, and it self-levels,” he writes. “So, it’s almost impossible to overbrush a piece of trim where the paint starts dragging. You have time to apply and lay it off with much less worry about it drying up or brush marks showing.” He also likes Benjamin Moore’s Insl-X Cabinet Coat for trim and cabinets and Kelly-Moore DuraPoxy for trim, and he uses Miller Paint’s Evolution and Premium products on drywall. Joe Cook, former painter and current partner at Catalyst Construction in Prairie Village, Kansas, starts with a list of preferred sheens: Ceilings get flat paint; walls get eggshell; trims, doors, cabinets, and exteriors get satin. Before making recommendations, Cook notes, “I don’t know if I would consider these cutting edge, but they are tried-and-true products that we stand behind.” For ceiling paint, he likes Sherwin-Williams ProMar 400, Behr Premium Plus Interior Ceiling Paint, and Kilz water-based ceiling paint for its hiding and stain-blocking qualities and low odor. For walls, Cook chooses Benjamin Moore Regal Select interior paint, Sherwin-Williams ProMar 400, or Behr Premium Plus, depending on the project and budget. For trim, doors, and cabinets, he specs Benjamin Moore’s Satin Impervo or their Advance waterborne alkyd paint. The first, he writes, is a “great paint that brushes well and is durable. It does have an odor and will yellow over time.” The latter he likes for its lower VOCs and non-yellowing characteristics, though, “It is not as durable as an oil-based enamel,” he adds. Outside, Sherwin-Williams’s Duration and Benjamin Moore’s MoorGard Low Luster are his go-to products for their durability and long-lasting color. Finally, we spoke to Brooke Cambridge, owner of BLC Painting in Boston, who is a loyal Benjamin Moore customer and uses their Ultra Spec ceiling paint, Regal Select and Aura for walls, Advance on trim, and Regal Select and Aura products for exterior work. One alternative she recommends is Fine Paints of Europe for interior trimwork. —Brian Pontolilo, editorial director

|

Reading the label won’t help

In any supermarket on any given day, you’ll find someone in an aisle carefully reading a label for the nutritional information it offers. Calories, sodium, saturated fat, sugar—it’s all there. Do you get the same level of detail when shopping for paint? Not so much.

Take, for example, the label on a 1-gal. can of Sherwin-Williams Resilience, an exterior acrylic latex paint that lists online for almost $75. After water, the most abundant ingredient is “Acrylic Polymer 25852-37-3,” whose CAS registry number identifies it as a butyl acrylate-methyl methacrylate polymer. The paint also contains titanium dioxide (called TiO2 in the trade), nepheline syenite (a mineral pigment and filler), and zinc oxide, an additive for stain blocking and mildew resistance. Unless you’re a chemist, there’s not much here that will ring a bell. And even if you were a chemist, without more specific information it would be difficult to compare this paint to a competitor’s paint.

One useful bit of information is that the paint contains less than 50 g of VOCs per liter. That’s low enough to meet current air-quality standards in Southern California and well below the federal limit.

“For the most part, the general categories of component types that are in there are very similar,” Laird says. “If you look at the polymeric binders, whether it’s acrylic or a cheaper form of acrylic, we have similar components as others. I wouldn’t say there’s a huge difference.” However, paint manufacturers also strive to set some of their products apart by meeting specific consumer needs, such as scuff or stain resistance. In these instances, big manufacturers with a lot of resources will be able to draw on their own chemists to develop unique resins, or borrow resin chemistry from another business unit, as PPG did in developing its UltraLast paint brand.

The paucity of useful information on a paint-can label may prompt consumers to look elsewhere for information: Consumer Reports reviews, online reviews, or a recommendation from a professional painter or even a neighbor.

“There’s virtually no way to get that from the can,” Welch says. “If you don’t have access to some testing, which every consumer does if they want to look in our approved product list online, it would be difficult for them to understand. The easy answer is that price is a pretty good indicator of quality. Basically, if you want to make paint cheaper, you’ve got to take something out, and the most expensive, top-line brand from any manufacturer is generally their best-performing product.”

This “approved product list” is an online database at the Master Painters Institute where anyone can look up a paint to see if it qualifies. The tests, which MPI devised itself, are not designed to show which paint is best. The standards are more like model building codes, setting minimum performance criteria for what Welch describes as “dependable performance over the long term.” The standards, he says, are used by both the U.S. and Canadian governments.

BRUSH BASICSPaintbrushes have three parts: a handle, a ferrule, and bristles. Handle sizes and shapes are about balance and comfort. Ferrules are about durability—corrosion-resistant ferrules will not rust, which keeps rust from bleeding into the paint. Bristle sizes and shapes are chosen for the task—a large, flat-bristled brush will make quick work of painting siding; a smaller, angled brush is suited for jobs like painting stair parts. Importantly, bristles should be matched to the type of paint being used. Latex paints generally require synthetic bristles. Oil-based paints can be applied with synthetic or natural bristles. Some paints are very specific about the bristle requirements, so always check to see what the manufacturer calls for.

|

Prep and application are important

Just about any painter will tell you that surface prep is key. Welch adds one other pointer: Don’t forget that paintbrushes and technical skill count for a great deal.

“Cheap brushes are a waste,” he says. “The better the brush, the better the application. Painting is a trade. Its become demeaned by the DIY movement. Most do-it-yourselfers could never rival the application skills of a master painter.”

Modern acrylic paints are good and getting better, but they are not dramatically more durable than they were 10 years ago, says Tim Leahy, director of architectural finishes for historic restoration and custom projects at Kirby Perkins Construction, a Newport, Rhode Island, firm that tackles high-profile jobs on historic homes. In harsh climates, even the best paints available will need recoating or touching up before too long.

“Take a gallon of oil with heavy-duty resins and throw in some lead and apply that,” he says. “You might not live forever, but that paint job is going to last forever. With modern paints, we tell people in shoreline areas that the paint will last 1000 days before it needs attention.”

|

From Fine Homebuilding #297

To view the entire article, please click the View PDF button below.

View Comments

What about ceramic coatings? How does ceramic coatings from a company like rhinoshield compare to these paints? Is a ceramic coating better on the exterior of a house in the southeast?