Installing Recessed Lighting

Locate and cut the hole, wire the recessed fixture, and then secure the can.

As the name implies, recessed lighting fixtures fit into the space above the ceiling. Recessed fixtures produce a strong downward cone of light and are frequently used to provide general illumination, to illuminate work areas such as in kitchens, or to accent art, tables, or other features.

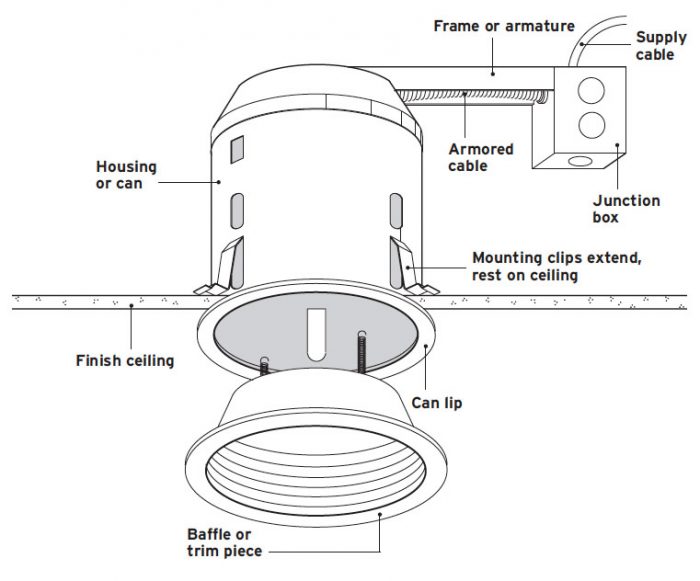

In new construction, recessed fixtures come with steel frames and bars that fasten directly to the ceiling framing. In remodel installations, as shown in the drawing below, recessed fixtures are secured to the drywall or other wallboard via mounting clips. With the advent of LED light sources, recessed fixtures come in a wider variety of sizes and outputs and can fit in even the tightest of spaces.

Recessed Light Fixture

Recessed light fixtures vary. The low-voltage model shown in the photo sequence below has a transformer at the end of its assembly to reduce line voltage. This drawing shows a model that runs on line voltage (120v), so it has no transformer. If the unit is watertight, it will have additional trim or lens elements. Closely follow the installation instructions provided with your fixture.

Retrofitting recessed lightingIn retrofit installations, the supply cable to the recessed lighting unit typically comes from an existing ceiling box or nearby switch box. The supply cable feeds to an integral junction box on the fixture. Finding the nearest power source and fishing the wires often means thinking spatially: The nearest power source may be in another room or on another floor. If the recessed fixture is a low-voltage unit, it will come with a transformer, which reduces the 120v current of the supply cable. |

Cutting a Ceiling Hole for Recessed Lighting

There’s no absolute rule on where to place a recessed light, but in a small space, such as a shower alcove, a fixture centered in one direction or another will look best 1. In addition, you may want to use a stud finder to avoid hitting ceiling joists above.

Drill a pilot hole to see what’s above 2 and to make sure there’s room for the can. Make the hole small because if there’s an obstruction above it, you’ll need to patch it. After drilling the hole, you can insert a 4-in. piece of bent wire and rotate it to see if it hits a ceiling joist.

|

|

|

Safety AlertTo avoid hitting pipes or cables when drilling into a ceiling, use a bit that’s 1 in. long—just long enough to drill through the plaster or drywall. Use a cordless drill to further reduce the chances of shocks. |

Also, use the small pilot hole to keep the centering bit of a hole saw from drifting. Keep the drill vertical, and the circle of the sawblade parallel to the ceiling 3. There are special carbide hole saws for drilling through plaster. A bimetal hole saw will also cut through drywall, but plaster will quickly dull the blade. Wear goggles.

If the hole saw is the right size for the can, you won’t need to enlarge it. But for the light shown here, the saw was a shade too small, so the installer used a jab saw to enlarge the hole slightly 4. In a pinch, you can also use just a jab saw to cut the hole.

|

|

Test-fit the unit 5. Although you want the can to fit snugly, the unit’s junction box and transformer also need to fit through. The black box about to enter the hole is the transformer.

Wiring a Recessed Fixture

To wire a recessed fixture, remove a Romex knockout from the unit’s integral junction box 1. Inside the knockout, there is a spring-loaded strain-relief clamp that will grip the incoming cable, so you don’t need to insert a Romex connector. Run a length of (unconnected) Romex cable from the nearest power source and feed it into the knockout just removed. Of course, the cable must not be energized when you are working on it. (To wire the box with AC or MC cable, remove one of the circular 1⁄2-in. knockouts and insert an appropriate connector.)

|

|

| PRO TIP: If you have access to the space above a ceiling fixture, staple the Romex to a joist, leaving at least 12 in. of free cable so you can push the fixture components into the hole. A cable that’s too short may prevent this. |

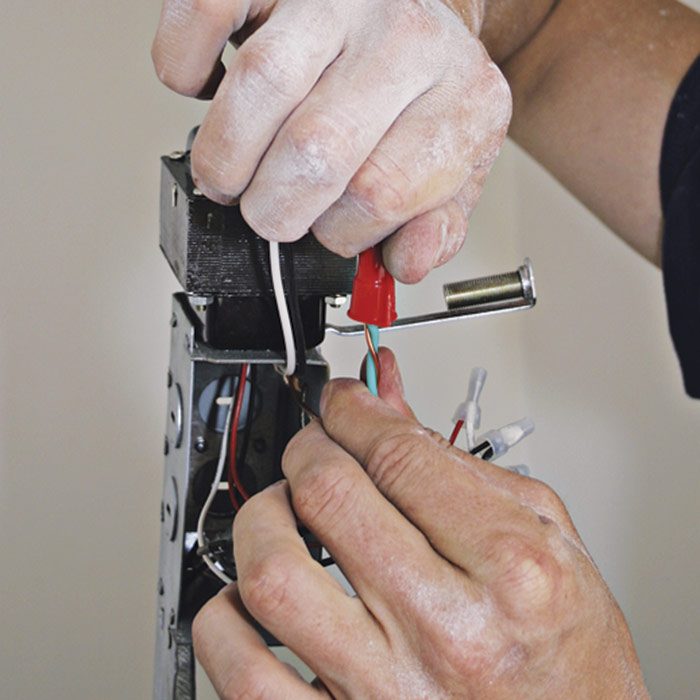

Inside the fixture’s junction box will be two sets of wires that were spliced at the factory. They connect the secondary wires that run from the transformer to the socket. (At the transformer, the current is reduced from 120v to 12v, so polarity is no longer an issue.) There are also three unconnected fixture leads in the box, to which you’ll splice the supply wires 2.

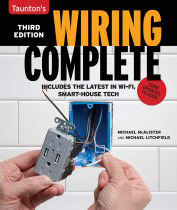

Using wire connectors, connect the incoming ground wire to the green fixture lead, the incoming neutral to the white lead, and the hot wire to the black fixture lead 3.

|

|

|

Tuck the spliced wire groups into the fixture junction box 4. At the right of the junction box is a piece of threaded rod that can be adjusted to support the transformer at the correct height. Snap the junction box cover 5 closed. As with other outlet boxes, code determines the number of wires you can splice in a fixture junction box, based on the cubic inches in the box.

Securing the Can

Once the recessed lighting fixture has been wired, push the fixture into the hole, being careful not to bind the Romex cable as you do so 1. If the fit is snug, use the side of your fist to seat the lip of the fixture flush to the ceiling 2.

Use a screwdriver to push up the spring-loaded clips that pivot and press against the back face of the drywall to hold the fixture snugly in place 3. To remove the fixture later, pop out the clips.

Insert the bulb (the fixture here uses an MR-16 bi-pin halogen bulb) into the fixture socket 4. Here, the installer is gripping the lamp’s rim, to keep the sides of the lamp clean. Skin oils can cause hot spots on the very hot-running lamps, shortening the life of the bulb. The lamp pins should seat securely. Install the trim piece—this one has a gasket. Snap in the lamp and socket, and push the assembly up into the can. The three arms on the side of the assembly will grip the inside of the can 5.

|

|

| PRO TIP: The pros apply a tiny dab of anti-oxidant paste to the lamp pins before seating them in a fixture socket to prevent oxidation. A good practice, but not imperative. |

Excerpted from Wiring Complete, 3rd Edition (The Taunton Press, 2017) by Michael Litchfield and Michael McAlister

Available in the Taunton Store and at Amazon.com.