Butt Boards for Smooth Ceilings

These butt boards are easy to make on the tablesaw and create a recessed drywall-panel joint that's less visible and easier to finish.

Finishing the butt joints where the short ends of drywall panels meet takes more time than finishing the seams where the tapered, long edges of panels meet. Because there isn’t a recess at the butt, you get a buildup of joint compound. To combat this issue, we use butt boards.

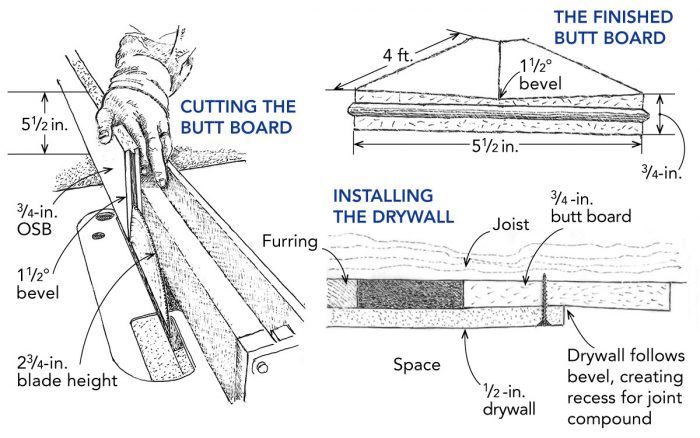

There are ready-made butt boards that you can buy, but we like to make our own. We use ¾-in. OSB and rip 4-ft. pieces into 5-½-in. strips. We set our tablesaw’s blade height to 2-¾ in. and the bevel to 1-½° and run the strip through the saw. Once one side is beveled, we flip the piece and bevel the other side.

When using butt boards, hang the drywall panel so that the butt end lands in about the middle of a stud, joist, or rafter bay. Once the drywall is fastened to the framing, we install the butt board on the floating end of the panel.

The next piece of drywall is installed on the other side of the butt board. The drywall ends follow the contour of the bevel, creating a recessed joint that’s less visible and easier to finish.

— Aaron Miller; Pollard, Ark.

From Fine Homebuilding #298

RELATED STORIES

Got a Tip?

Do you have any great tips like this one on making drywall butt boards for smooth ceilings? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at tips@finehomebuilding.com, or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

View Comments

It's a lot faster (and safer) to assemble butt boards by tacking sheetrock shims along the outside edges of a 5 1/2" X 48" rip of OSB.

ClayM2, Can you explain your method more, or put up a sketch? I I cannot picture what you are saying.

And, what's a sheetrock shim?

Domo

These ready made tapered strips are now available at your local sheetrock supplier. No fabrication needed!

TTTTT, Sheetrock shims are 1 1/2" w x 36"l strips of 1/16" cardboard. You staple them to the edge of a wall stud that is out of plane (low) with the studs to the left and right.

To make a butt board with sheetrock shims, take a 6"x 48" cut from 1/2" OSB. Staple two thicknesses of sheetrock shims to the long edge of the OSB. Do this to both long edges. This will create the taper that is needed to pull in the butt end of the drywall. When you install butt boards, stager the butt board lengthwise so that it overhangs the sheetrock by 10" to 12". This will ensure that the next row of sheetrock stays in the same plane and makes a smooth joint.

Most houses have a single bottom and double top plates, for a total of 4-1/2". That leaves about 92" open space, plate to plate, not enough room for 2 butt boards @ 48" each.

While I can easily see the drywall dipping down into the butt boards, between the plates, and making life much easier for the tapers, what happens at the plates? The drywall has to stay in plane with the plates and studs, so there's no depression for the tape nestle down into.

I trim the butt boards to length, leaving them a few inches short of each plate. To answer the second part of your question, the corner seam at the ceiling is going to get its normal 3 coats of mud and cover that seam. At the bottom the baseboard covers most of the seam, so I go a little lighter on the mud in that area and just blend in the seam.