Podcast 338: Long-Lasting Fence Posts, Leaky Basements, and Seasonally Wet Walls

Brian, Matt, and Patrick hear from listeners about storm windows and putting dishwashers in weird places before taking questions about insulating walls without sheathing, the best way to build a fence, and how to make cancelled basement windows watertight.

Follow the Fine Homebuilding Podcast on your favorite app. Subscribe now and don’t miss an episode:

|

|

Help us make better episodes and enter for a chance to win an FHB Podcast T-shirt:

www.finehomebuilding.com/podcastsurvey

Carin extols the virtues of aluminum storm windows. John shares his method for supporting countertops over dishwashers without cabinets. Ian explains the commodities market. Brian asks how he should insulate his old walls. Andrew asks how make fence posts last longer. Dave wants to know if it’s normal for walls to look wet on the inside. Shawn asks what to do about the water seeping into his basement.

Editor Updates:

-

- Patrick’s wood rack

- Matt’s never-ending vines

- Brian’s house hunting

- Jeff’s dishwasher install

Listener Feedback 1:

Carin from Washington, DC writes: Dear FHB Podcast, I’m an avid listener, a serial old-house owner who works in historic preservation and is learning a lot from you guys even if I don’t do much DYI anymore.

I was surprised that two successive podcasts featured extended discussions of storm windows with no mention at all of good ol’ triple-track storms—i.e., double-hung storm windows with screens, permanently installed. They are ubiquitous here in DC, on the early-20th-century houses that make up the vast majority of our housing stock, and I imagine they’re still the most common form of storm windows in lots of places. Of all the postwar “improvements” to prewar houses, aluminum storm windows may be the only category that’s held up in value and function.

My house was built in 1922 and I’m lucky to have all of my original double-hung wood windows in good shape. I’ve replaced sash cords where necessary, so they all operate, but I haven’t yet done a complete rehab with new weatherstripping. But because I have triple-track storms, I have no drafts at all when the storms are closed. It’s comfortable to sit by the windows in winter and it’s very, very quiet inside. When I want fresh air, in the short spring and fall space between heating season and air conditioning season, or if I need to air out a room, it takes less than a minute to slide the storms up and the screens down.

|

|

I admire the old-fashioned wooden storms that you have to take down and switch out for screens seasonally, but they sure are a hassle, and not easy to store, especially in a city house without outbuildings—plus you have to decide on one magic day, twice a year, whether it’s window-opening season or not, which doesn’t accord well with the way the weather actually works these days. Ditto for interior storms: they’re great for some applications, but they don’t make it easy to get fresh air when you need it. I’m with Matt on wanting to be able to open my windows whenever I feel like it.

The Historic Preservation Office here in DC actually encourages storm windows as one way of weatherproofing and preserving original wood windows, and I read the same from many other preservation authorities elsewhere. Storms and screens are not even subject to preservation review in DC historic districts; they’re treated under the category of repair and maintenance. They do impede the exterior view of window details a little bit, but the attitude in much of the preservation community seems to be that their value in helping keep historic windows in place through better comfort and decreased maintenance costs is a good trade-off for slightly diminished visibility.

Attached: a couple of pics of my triple-track storm windows. Note that you can see the brackets for hanging the old wooden storms and screens still in place above the windows. The aluminum storms’ frames are pretty low-profile, they’re painted to match the rest of the trim, and the divided lites of the original windows are still clearly visible.

Looking forward to the next episode, as always, Carin.

Related Links:

Listener Feedback 2:

John writes: Hi all! This is a quick response to your discussion of supporting a counter over a dishwasher that isn’t surrounded by cabinets in the usual fashion in podcast 332. Since I have had a bad habit of sticking dishwashers in weird places, I’ve come up with a technique for enclosing the dishwasher and supporting a work surface above it. I attach a cleat to the wall behind the dishwasher to support the back of the countertop, and I bring two thin legs down on either side in the front of the unit to carry loads on the counter to the floor. This gives the front a finished look and is very study without the need to build a full carcass. I think your suggestions on the podcast were good too, but you overlooked one critical thing: the requirement for anti-tip anchoring. A dishwasher has to be firmly attached to surrounding structure so that it doesn’t tip forward when loaded racks are pulled out or kids push down on the open appliance door.

|

|

|

Cheers! John

Listener Feedback 3:

Ian writes: Patrick, Just as there is no answer to the question “what should a bathroom remodel cost and why?” that will satisfy a client, “what should a sheet of OSB or a 2×4 (or enter any other commodified consumer good here) cost and why?” has no answer that will satisfy the consumer.

Understanding all of the factors that go into pricing a commodity requires a level of macroeconomic understanding that, let’s be frank, if any of us possessed we wouldn’t be builders. On a simplified level the commodities market exists to provide raw material producers with a stable marketplace that provides near 100% certainty that the producer will be able to sell their raw material at a price that will allow them to stay in business. This is the basics behind why goods like steak, gas and 2x4s cost more or less the same, within a few %, no matter where you buy them across a large geographical area.

Through my role as an estimator and Project Developer I have been on calls and webinars throughout 2020 that laid out how the increased global demand (the construction industry is about 40% of the planet’s GDP) coupled with pandemic and weather event shutdowns are the driving factors that led us here.

Thinking about this problem in terms of lumber reps being coy or can government intervention help reduce prices is missing the forest for the trees. If you can’t stand the rising cost of gas prioritize a more efficient vehicle or change your habits to include public transport. And if the cost or material puts your desired project over budget use the setback to rethink project goals, construction methods or design. We live in a golden age of construction options, take the agency (shoutout to Andy Engel) to look inside yourself for the answer before decrying the system.

(soapbox yielded)

Best, Ian

And Ian’s reply on rising building costs: It certainly is. Lumber, Romex, PVC pipe, well casing. The list goes on. I can say with near metaphysical certitude that without all of the training and work that I have put into being an estimator over the last few years, this project would have been a financial disaster. As of right now we are still tracking within sight of my goal of $100/sqft (267K).

We have had to get creative.

-Polished concrete basement floor instead of tile or hardwood over a no-concrete slab

-Marvin Essential fiberglass windows instead of wood aluminum clad (actually really happy with these windows)

-Building my own euro style frameless cabinets using off the shelf drawer components (I can see you rolling your eyes)

-DIY wide plank floor from lumberyard 1x8s (I can hear you yelling at NO! at your computer)

The biggest thing that I have done is anything that I can turn from an expensive subcontractor provided service (footing and wall forming and stripping, digging for the underslab plumbing etc.) to just my own manual labor, I have done it. The flip side is that anything that would take me a long time to accomplish (soffit fascia, Flash coat of spray foam on the roof, shingling the roof) but can be done quickly, confidently and reasonably by a low-level sub, I have taken off my plate.

I’m looking forward to, hopefully, making time to write a diary of a self-builder style blog for the FHB HOUSE page once my project is up. Brian and Jess have been supportive in telling me to write as much as I can.

Hell or high water, hook or crook I will complete my house before Andy Engel. Hopefully.

Question 1: Can I use mineral-wool insulation in a wall with no exterior sheathing?

Brian writes: Good day Fine air sealing and insulation podcast crew! I am faithfully catching up on your podcasts and am on episode 299.

My wife and I decided to install some closet organization systems in our (2) master bedroom closets. Our house is a 1890s era build with clapboard siding nailed right to the studs. How do I know? I demolished the exterior wall plaster, lathe, and formaldehyde foam insulation to find felt paper(?) and the claps nailed right to the studs. We decided to demo the walls because there was some failing plaster, a door we wanted to close in, and a wonky wall that I didn’t think I would be able to install the storage system to (think 1″ out of flat in a 5-foot wall which i found out was a broken stud that was definitely split when they originally installed the p & l.

I read the article How to Insulate Walls With No Sheathing already but want to staple 30# felt paper to the back of the clapboards and use mineral wool insulation. Am I crazy? Will this fail and rot? I feel like this is a hybrid version from the article. I don’t want to add depth to the walls since it isn’t a huge closet and I don’t want to use spray foam.

Attached are a few pictures for reference. Also, included the kitchen renovation and stairwell renovation “before and afters”.

|

|

|

|

|

|

|

|

Related Links:

Question 2: What is a durable alternative to setting wooden fence posts in the ground?

Andrew from Victoria, BC writes: Dear FHB podcast team, This is my first time submitting a question to you and I feel a little guilty that it’s not about something more technical like the r-value vs. cost of ‘X’ and ‘Y’ insulation, or how to improve my diy blower door test machine – which sort of worked as intended.

My question is about fence posts. Yes, dumb old fence posts. So, here’s the deal; we bought this house in Victoria, BC Canada a couple of years ago and I’ve been slowly renovating it as budget and time permit. So far, I’ve combined two bedrooms into a larger master suite (taking down an interior wall and building a massive walk-in closet – as requested by the ‘client’, my wife), sound proofed and updated the guest room, and built out the home office. On to the fence – If you can’t tell already, I’ve been putting this off. The existing privacy fence along the back of our property is about 400 feet of wooden carnage. Several posts lean like a sailor on shore leave, panels coming off, it’s in bad shape. The thing is, the fence is only six or seven years old. Not of the materials seem rotten, it’s just that the posts have shifted over time. The soil here is pretty wet because the climate is a temperate rainforest, so I’m thinking that isn’t helping matters.

Instead of rebuilding the fence with the typical fence post footing (hole, gravel, pt post, concrete), I’m thinking of pouring a sonotube footing and embedding a Simpson MPBZ base so that I can more easily repair the fence in the future as required. Alternatively, I could also use a steel pipe as the fence post and wrap it with cedar boards to match the panels. I know this will be more time and money but I don’t mind too much because this is our forever home and I’ll be the one fixing this thing in the future anyway. What do you think about this idea? Will it hold up? Am I overthinking this (definitely)? A few relevant design details – This will be a privacy fence between us and our neighbors so no gaps in the panels to allow the wind through but, the fence is located between the backs of two homes on heavily treed lots so while it does get windy here the back yard is fairly protected.

|

|

|

Thanks in advance and thanks ever so much for all of the great info and good company on those long days working alone on the house.

All the best,

Andrew

The existing fence is made of PT posts and rails with cedar boards for the panels (photos attached). As per budget, I’m thinking (hoping) for around 15 USD (about 19 CAD) per foot but I don’t yet know how reasonable that is since I haven’t done my homework pricing everything out at the local lumber yards.

Related Links:

Question 3: How can you tell if there’s a moisture problem inside your walls?

Dave writes: Hey Podcast Crew! I am continually impressed with the quality of the podcast – thank you all for doing it!

I was listening to episode #332 and the discussion of mossy roofs. It made me remember these photos which I have attached to this email. I took them some years ago and intended to send it to the podcast crew of that time. This former Montpelier, VT gas station has since been razed and is now a parking lot, but I digress.

I think it’s truly a fine example of the power of either copper or zinc in holding roof moss at bay! It’s a little hard to tell in the photo but I think that’s a copper roof boot.

|

|

…

I do have a question that may be difficult to answer, but I wonder if, with Brian P back after a stint at GBA, you might have some insight to this. I build in climate zone 6A. I am wondering if there’s any answer to how wet one could expect an exterior wall to be after a long, somewhat very freaking cold winter? I ask because I often open up walls in late winter or early Spring, which, (Patrick – I’m sure you know this already) around here can span from late Feb thru late May. Sometimes sheathing will look wet or at least damp. Sometimes it will be quite wet and bulk water can be squeezed out if you press on it. Cellulose, for example, can feel discernibly damp. Usually I’m exploring for rot after having found it elsewhere – Vermont houses seldom disappoint in this regard. Sometimes wall areas will be wet but everything appears to be sound – like yellow plywood and studs. It has taken on a lot of water, but it doesn’t seem to be anything the wall can’t handle.

So. My inner-carpenter and scrupulous ethos get all flustered when I see wet walls and I feel inclined to root out the source of the wetting which can be difficult, disruptive, complicated, and expensive. But sometimes I wonder if some of this is normal winter moisture loading and I shouldn’t lose too much sleep or spend too much of the client’s money solving what may in fact be a non-issue.

What do you all think? Is there a way to know if a level of moisture in a wall is problematic or safe? I mean, beyond just making a call that, “this wall is wet but so far not moldy = a) fine! or b) not fine or c) all of the above”? Should exterior walls ever be obviously visibly wet at the tail end of winter, or should the seasonal moisture loading be more of something you need to probe for with a moisture meter?

Anyway, I hope you enjoy the drama offered by the photos. The fact that I took these photos over four years ago, saved them, and spent a bunch of time finding them to send to you all is pretty nerdy, I admit, but I think I might just be in good company in this regard!

Thanks again! Keep up the great work!

Related Links:

Question 4: How can I seal former window openings in my basement so they don’t leak?

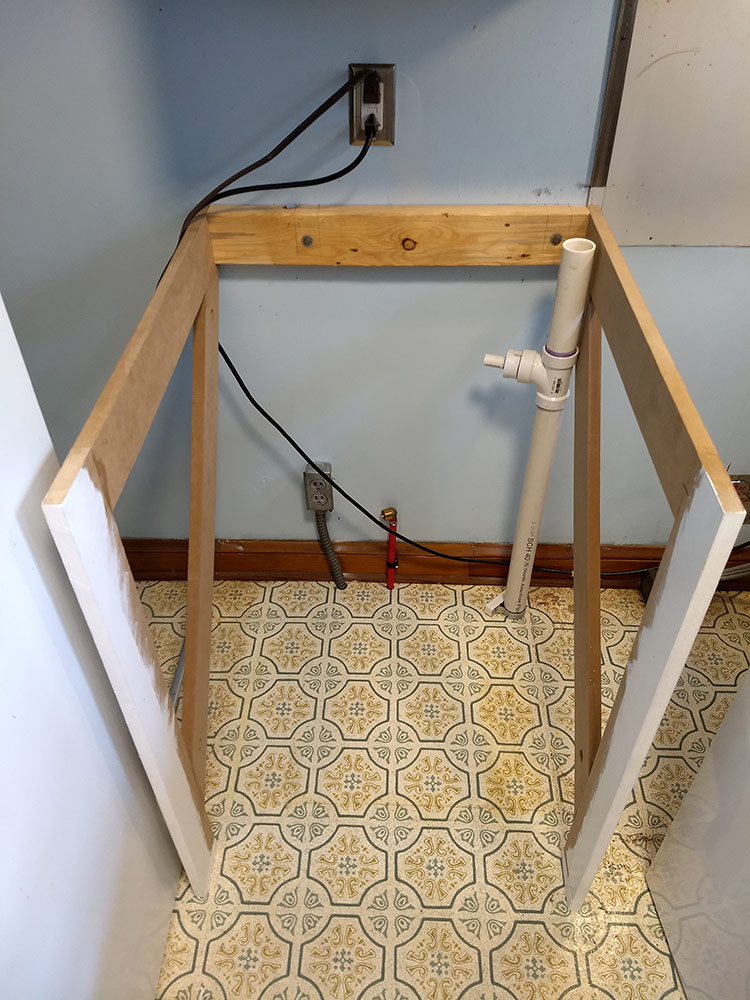

Shawn from Brunswick, Maine writes: Hey FHB Podcast Crew, We live in a 1970s-era garrison colonial in Brunswick, ME. A few years ago, we tore out a rotten ground-level deck off the back of the house and had our favorite landscaper install a beautiful stone patio. I was here while they were prepping and installing it. They’ve done other work for us and do a good job. The base seemed to be prepped well and it was graded away from the house toward a dry well and rain garden. To prep for the patio, I had to remove two metal basement windows (that whole process was miserable) that were below grade with window wells. I cut out the windows and filled in the space with mortared cement blocks. When we first moved into our home, we spent a fair amount of money air sealing and insulating the attic and basement, which includes spray foam to 4 feet below grade. From the inside, I looked at these blocked off holes and thought that I could fill them in with rigid foam, which I did in layers, sealing the seams with spray foam. When the right exterior conditions occurred, I noticed water dripping down over the spray foam under one or both of the windows. In a moment of clarity, I worried that the rigid foam was preventing the block from drying to the interior, so I pulled all the foam out. Just the other day, we had some warmer weather and rain and water was again seeping in through the blocked-off windows. We have no water intrusion anywhere else in the basement, except sometimes where the bulkhead doors are, but that’s a different story.

|

|

|

Any suggestions about what I can do here? My thought was to pack and cover all the seams and block with hydraulic cement, but I might need some help! I’m terrified that our beloved patio is going to be the root cause of flooded basements and wall rot on the 1st floor wall of the back of the house for the rest of my life in this house, which we love. My wife thinks I’m crazy, but the one rule I have with any renovations or updates we try to undertake is: Don’t do anything that we have to undo down the road! Our patio would be an expensive undo…

Thanks for the podcast, —Shawn

Related Links:

- What’s the best way to fix a crack in a foundation wall?

- Waterproofing a Basement From the Inside Can Be a Challenge

Visit the Taunton Store • Magazine Index • Online Archive • Our First Issues • All Access

Help us make better episodes and enter for a chance to win an FHB Podcast T-shirt: www.finehomebuilding.com/podcastsurvey

If you have any questions you would like us to dig into for a future show, shoot an email our way: fhbpodcast@taunton.com.

If we use your question we’ll send you a FHB Podcast sticker!

FHB Podcast T-shirts!

Represent your favorite podcast! Available in several styles and colors. Made from 100% cotton. Find the Podcast t-shirt and more cool products in the Fine Homebuilding Store.

This episode of the Fine Homebuilding podcast is brought to you by BuildBook.

A lot of construction pros have a common problem; your construction management software is either non-existent, or it is too slow and too complex. It shouldn’t be bogged down with complicated features that you have to attend an academy to learn how to use. You need software you can start using DAY ONE without training… That is faster and more reliable than your notepad. That allows you, your team and your clients to always know what’s getting done and when. And your software should reduce stress, not increase it. The solution? BuildBook.

BuildBook is built for today’s modern builder with everything you need, nothing you don’t. Whether you’re a one man operation or a business with a large crew, BuildBook has plans to fit your budget. No nagging sales calls, tricky upsells or hidden fees. Head over to BuildBook.co and sign up for a free 10-day trial — and don’t forget to mention that you heard about them on the Fine Homebuilding podcast.

Visit BuildBook.co for more.

Fine Homebuilding podcast listeners can now get 20% off anything in the Taunton store, including Insulate & Weatherize.

Use the discount code FHBPODCAST to take advantage of this special offer.

We hope you will take advantage of a great offer for our podcast listeners: A special 20% off the discounted rate to subscribe to the Fine Homebuilding print magazine. That link goes to finehomebuilding.com/podoffer.

The show is driven by our listeners, so please subscribe and rate us on iTunes or Google Play, and if you have any questions you would like us to dig into for a future show, shoot an email our way: fhbpodcast@taunton.com. Also, be sure to follow Fine Homebuilding on Instagram, and “like” us on Facebook. Note that you can watch the show above, or on YouTube at the Fine Homebuilding YouTube Channel.

The Fine Homebuilding Podcast embodies Fine Homebuilding magazine’s commitment to the preservation of craftsmanship and the advancement of home performance in residential construction. The show is an informal but vigorous conversation about the techniques and principles that allow listeners to master their design and building challenges.

Other related links

-

- All FHB podcast show notes: FineHomebuilding.com/podcast.

- #KeepCraftAlive T-shirts and hats support scholarships for building trades students. So order some gear at KeepCraftAlive.org.

- The direct link to the online store is here.