A Better Way to Demo

Portland, Ore., provides a model for deconstructing houses that is better for people, the planet, and profit.

Synopsis: A deconstruction ordinance, passed in Portland, Ore. in 2016 and updated in 2020, prohibits the use of heavy machinery for structural demolition and requires that it be done by a city-certified deconstruction contractor. The process creates less dust and neighborhood disturbance, enables more-effective abatement of hazardous materials, and allows valuable materials to be salvaged for reuse.

As people and money pour into thriving cities and blight spreads through others that struggle, an increasing number of old homes are crunched by the excavator and dumped in the landfill. Asbestos-wrapped ducting goes undiscovered inside walls, lead is hidden in layers of paint, and when the excavator shovel comes crashing down, a wide array of toxic substances are released as airborne dust. At the same time, valuable building materials go unrecovered, with a high cost in embodied carbon. None of these things is good for the health of people or the planet.

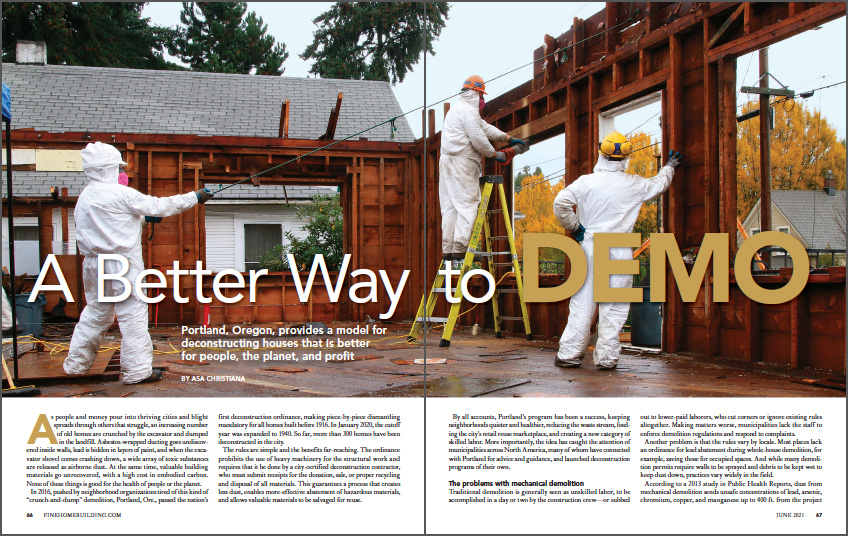

In 2016, pushed by neighborhood organizations tired of this kind of “crunch-and-dump” demolition, Portland, Ore. passed the nation’s first deconstruction ordinance, making piece-by-piece dismantling mandatory for all homes built before 1916. In January 2020, the cutoff year was expanded to 1940. So far, more than 300 homes have been deconstructed in the city.

The rules are simple and the benefits far-reaching. The ordinance prohibits the use of heavy machinery for the structural work and requires that it be done by a city-certified deconstruction contractor, who must submit receipts for the donation, sale, or proper recycling and disposal of all materials. This guarantees a process that creates less dust, enables more-effective abatement of hazardous materials, and allows valuable materials to be salvaged for reuse.

By all accounts, Portland’s program has been a success, keeping neighborhoods quieter and healthier, reducing the waste stream, feeding the city’s retail reuse marketplace, and creating a new category of skilled labor. More importantly, the idea has caught the attention of municipalities across North America, many of whom have connected with Portland for advice and guidance, and launched deconstruction programs of their own.

The problems with mechanical demolition

Traditional demolition is generally seen as unskilled labor, to be accomplished in a day or two by the construction crew—or subbed out to lower-paid laborers, who cut corners or ignore existing rules altogether. Making matters worse, municipalities lack the staff to enforce demolition regulations and respond to complaints.

Another problem is that the rules vary by locale. Most places lack an ordinance for lead abatement during whole-house demolition, for example, saving those for occupied spaces. And while many demolition permits require walls to be sprayed and debris to be kept wet to keep dust down, practices vary widely in the field.

According to a 2013 study in Public Health Reports, dust from mechanical demolition sends unsafe concentrations of lead, arsenic, chromium, copper, and manganese up to 400 ft. from the project site. Draw an 800-ft.-diameter circle around any urban lot, and it’s likely to include 50 or more homes. In cities economically pummeled by outsourced manufacturing, the inventory of outdated, failing structures is immense, and the effects of mechanical demolition extremely harmful to those living close by. In 2018, after blood tests revealed alarming levels of lead in children, Detroit paused all demolitions in its worst-affected zip codes until better mitigation measures could be introduced.

“There is no safe level of lead in the body, and children are most vulnerable to the potentially devastating health effects,” says Jordan Jordan, manager of the deconstruction program at Earth Advantage, a Portland nonprofit that provides training and certification for green-building practices. “Elderly people and those living with health problems also suffer disproportionately from toxins and particulate matter dispersed by traditional demolition.”

Toxicity isn’t the only blow to the environment from dirty demolition. Lost to the landfill are valuable, reusable building materials—from old-growth studs and planking to cabinets, architectural finishes, and vintage fixtures, each embodying the fossil fuels it took to produce them. “Most of the greenhouse gases associated with new building materials [are emitted during] manufacturing, not transportation and installation, so if you can reuse them, that’s a very good thing,” says Bryce Jacobson, a solid-waste-system planner for Portland’s metro region.

In Portland, construction and demolition debris accounts for 30% of the waste stream. Aside from “rendering hundreds of tons of reusable material worthless,” Jordan says, mechanical demolition also damages healthy soil, trees, and other mature landscape features, and it harms watersheds with toxic runoff.

The process and the payoff

The first step in a typical deconstruction project is asbestos abatement, carried out by a specialized contractor. Next, while waiting for the permit, the deconstruction contractor can get started on “soft stripping,” which refers to things like pulling out cabinetry, doors, appliances, lighting, and plumbing fixtures for donation. Those are often picked up by a local nonprofit on the same day.

Once the permit is granted, lead abatement can begin. The focus is on exterior siding and trim, where paint contains the highest lead concentrations. This step is now required in Portland for both deconstruction and demolition of all homes built before 1978; a rule that was inspired, at least in part, by the deconstruction movement. All deconstruction contractors are certified for this work.

After exterior lead abatement, the tough work begins. The roof, siding, interior trim, floors, tile, and lath/plaster or drywall are stripped away piece by piece to reveal the “lumber package,” which is the most valuable material for resale. In old Portland homes, the studs, beams, and wall and subfloor planking tend to be old-growth fir, with tight, beautiful grain no longer available from fast-growing modern forests. In homes outside the Pacific Northwest, other desirable woods are often exposed. In the end, all that’s left is the foundation and hardscaping, which will be broken up and recycled properly when excavation begins.

Better abatement and incentive for salvage

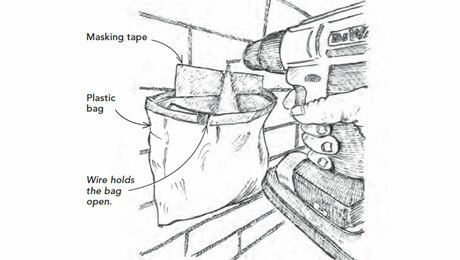

One of the many benefits of deconstruction is the continued abatement of lead and asbestos as the project progresses. If lead-painted trim is found on the interior, it goes in the same plastic-lined dumpster as the exterior trim. If lead paint is on the plaster, that can go down a chute to the basement, to be collected safely later. As asbestos-wrapped ducts are revealed, they are marked with red paint and the asbestos contractor returns for them.

For deconstruction contractors, the sale of salvaged materials is built into the bid, helping to offset the premium for deconstruction over mechanical demolition. Clients also receive a tax benefit for donated materials.

For Dermod Lovett, who has been deconstructing historic houses in Portland for 20 years—both remodels and tear-downs—the new ordinance means more business, better awareness, and less explaining. “We recycle plastic bags and bottles,” he says. “The very least we can do is recycle houses. The material in these homes is stunning. Our old-growth forests are no longer there, but the lumber still exists in these old houses. If we crunch it and throw it in the landfill, we are losing those forests.”

Green jobs and lessons for other cities

The process is better for workers, too. Lovett’s field employees get competitive wages and benefits, and much safer working conditions than the typical demolition crew. For example, they wear respirators well after lead and asbestos have been abated, to keep drywall dust and fiberglass out of their lungs.

Notably, Lovett has more competition these days. With 12 certified deconstruction contractors and counting, Portland’s ordinance has created a new category of green jobs, with a knock-on effect for the city’s entire salvage ecosystem, including private retailers who sell reclaimed wood, local contractors and furniture makers who use the material, and nonprofit donation centers like Portland’s ReBuilding Center—the city’s largest and longest-operating reuse center—and the Habitat for Humanity ReStores.

Portland’s deconstruction discussion turned serious around 2013, in conversations between employees and city officials at the ReBuilding Center. The tipping point came two years later, when demolition permits were peaking at 600 to 700 homes annually.

“It got ugly,” Jacobson says. “A wave of established neighborhoods were at war with developers. That’s what got our ordinance going. The idea is the little house still gets replaced, but [the ordinance] adds additional care and increases the cost for redevelopment.”

Portland’s neighborhood associations joined forces and met with the mayor and city commissioners, who in turn met with developers and industry professionals and made recommendations to the city council. In this way, the ordinance was shaped and passed.

A key condition for success was the strong local market for salvaged materials. Portland’s long-standing DIY movement has always embraced reuse, and reclaimed wood and vintage items have always been a big part of the Portland aesthetic. They are seen in coffee shops, boardrooms, and living rooms around town, and are now exported to hip spots across the U.S.

As for the builders, “a few were ruffled by costs going up,” Jacobson says. “But once they saw that there was going to be equal enforcement for everyone, and accommodations for special cases, they were OK. And after they tried it, they saw it wasn’t so difficult.”

Because of the money rolling into Portland—from California and beyond—the new ordinance and the premium paid for the process haven’t slowed the pace of development. But neighborhood associations are pleased with the new normal—enjoying the health benefits, the reduced noise, and the knowledge that old houses will be recycled and reused.

Each time another friendly yard sign reading “I’m required to be deconstructed to maximize materials for reuse!” goes up, it announces the new demolition process. Neighbors wander by and ask questions, and that increases awareness.

Third-party certification establishes street credOne of Portland’s early steps toward an ordinance was hiring a local nonprofit to make key industry connections and provide critical training. Earth Advantage (EA)—a Portland-based organization that certifies sustainable building practices—played matchmaker between local builders, developers, and reuse shops; they trained deconstruction contractors, providing invaluable feedback to city officials along the way. When the facilitator role was no longer necessary, EA turned its newly won expertise into a third-party standard for deconstruction. Called Safe + Sustainable Site Certification (S+S), the program offers local builders a way to certify their deconstruction projects, whether mandated by the ordinance or not. It enables them to market a comprehensive commitment to sustainable building practices.  The additional S+S requirements and $750 fee made sense for Josh Salinger of Birdsmouth Design-Build. (He is building a Passive House on the deconstruction site documented in this article.) “Certifying the process means the community doesn’t have to take our word for doing the right thing,” Salinger says. “They’ll know that a third party has verified that all of the processes have been done correctly and kept us to our word.” Among the elements mandated in the S+S standard are clear and effective communication with neighbors and neighborhood associations, increased measures for job-site safety, erosion control and other site-protection measures, better management of hazardous materials and dust, and more-detailed deconstruction methods. Although the S+S program is currently focused on projects in the greater Portland metro area, the company is interested in finding nonprofit partners and supporting pilot programs nationwide. To learn more and get in touch, visit safe-sustainable.org. |

Green shoots far afield

Shawn Wood is Portland’s Johnny Appleseed for the deconstruction movement. He is the construction waste specialist for Portland’s Bureau of Planning and Sustainability, and is responsible for leading the earliest discussions at the ReBuilding Center. In fact, it’s his phone number on the deconstruction yard signs. Well before the first ordinance passed, Wood was the point of contact for other cities looking to follow suit. “There was a lot of fanfare when Portland ‘cracked the nut,’” he says.

Shortly after the first ordinance passed, Portland was chosen to host the annual Deconstruction and Reuse Conference, held by the Building Materials Reuse Association (BMRA). EPA officials attended, Wood says, and helped set up the Bay Area’s Deconstruction Work Group, which draws interested parties from around the U.S. and Europe to its quarterly meetings.

Soon after the work group was launched, Palo Alto, Calif., made deconstruction mandatory for every demolished structure in the city, regardless of age. Soon after that, Vancouver, B.C., issued a deconstruction ordinance for all homes built before 1910, as well as a penalty for any demolition that doesn’t meet basic reuse and recycling requirements.

A mandatory ordinance isn’t the right path for every municipality—at least initially. Denver, Milwaukee, Minneapolis, Pittsburgh, San Antonio, San Francisco, and Seattle, among other cities, now offer some type of support for deconstruction practices, including online guides, links to local reuse organizations, and cash incentives in some cases. Minnesota’s Hennepin County, for example, offers up to $5000 to homeowners choosing deconstruction.

Conditions for success

Portland, Vancouver, and Palo Alto had a number of critical elements in place to make a mandate feasible: a metro government committed to waste reduction and recycling, the ability to absorb higher construction costs, and a robust market for salvaged material.

In Milwaukee, Wis., however, which passed an ordinance similar to Portland’s in 2018 covering homes built through 1929, the conditions were different, forcing the city to issue a stay on enforcement one year later. Because the city owns most of the aging inventory, the projects were city-run, with higher wage requirements, among other impediments. Secondly, the city lacked a robust salvage marketplace. Without the ability to take the lumber sale off the bid, costs were prohibitively high. “It’s all labor,” Wood says, “just hand-demolishing with no financial payoff.”

Portland experts agree. “There is currently a lot of focus on salvaging—keeping stuff out of the landfill—but less emphasis on reuse, which means that there aren’t sufficient resources to circulate those materials back into the community,” says Jackie Kirouac-Fram, executive director of Portland’s ReBuilding Center.

Reuse doesn’t have to happen locally, Wood points out, citing a nonprofit program in Baltimore that pays for deconstructing row houses by selling the reclaimed southern yellow pine to a company called Room & Board for a line of sustainably-sourced furniture.

“We can do whatever we want in Portland to fight climate change,” Wood says, “but if other places don’t follow suit, it’s a waste of time.”

Asa Christiana is a contributing editor and freelance writer in the Pacific Northwest. Photos by the author.

To view the PDF article, please click the View PDF button below.

RELATED LINKS