Antifracture Membranes

Apply a liquid, paste, or sheet covering on top of the substrate to prevent any cracks from radiating into the tile from below.

Also known as a crack-isolation membrane, antifracture membranes are liquid, paste, or sheet coverings that are applied on top of a substrate (such as drywall or concrete) before the tile is set. A membrane’s main function is to prevent cracks in the substrate from radiating into the tile and causing broken and/or loose tiles. Membranes also allow for expansion and contraction in the substrate and sometimes in the tile itself. Membranes also provide a waterproof layer between the backerboard and the surface it’s attached to. This helps prevent moisture from damaging, say, wood cabinets around a sink or walls around a wet area.

Always use an antifracture membrane on concrete slab floors, regardless of the type of tile to be installed. Because of earth movement under your home and the thermal expansion and contraction of the concrete, every slab floor has the potential to develop cracks over time. Floor slabs in newer homes are especially prone to developing hairline cracks due to the small gravel size (necessary for pumping concrete) and fast-drying concrete mixes used to save time during construction.

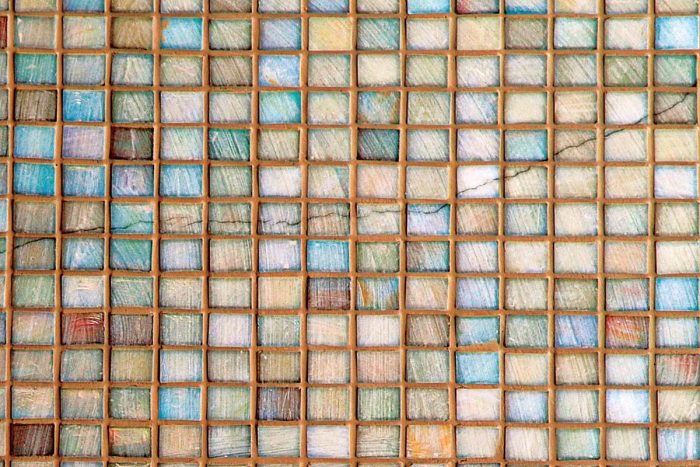

Glass tile expands and contracts at a much higher rate than does ceramic tile and stone, and its transparent nature reveals any cracks in the substrate. When glass tiles first became popular, the use of an antifracture membrane was only suggested by manufacturers. Now we wouldn’t think of setting glass tile without a membrane underneath it.

What can go wrong

Duct tape, kraft or building paper, and roofing felt of any type cannot be used as antifracture membranes. We have seen several failures of floors where someone tried to save money by gluing these materials to the floor.

Liquid and paste membranes

Liquid- and paste-type antifracture membranes are simple to use and provide an easy way to add waterproofing to substrates being prepared for tile installation. These products are an especially good choice if you’ve never used a membrane product before. Some waterproofing membranes come as one-part liquids that are to ready use out of the container, whereas others are two-part pastes that require mixing before application.

One-part membranes are thick liquids that are very easy and quick to apply. RedGard®, by Custom Building Products®, has the least odor of all the liquid membrane products we’ve tried (however, you should still ventilate the area in which you’re working). One-part membranes can be applied to counters, walls, or floors with a standard paint roller.

Just be sure to wear gloves and work clothes when working with liquid membrane, and keep it off your skin and clothes as it clings tenaciously to any surface it touches unless you wash it off immediately.

Paste-type waterproofing membranes, such as TECTM Triple FlexTM are two-part systems. The two components, which come in separate containers, are mixed together and then applied with a trowel. The mortar-like paste creates a very tough membrane, which works especially well to protect tile. On the downside, paste-type membranes have an extremely strong chemical odor and should be used only in properly ventilated areas. They also can take hours to dry.

| TRADE SECRET: For best results, always buy tile products (thinset, grout, and so on) that bear the insignia of a national tile association, such as the Tile Council of North America® (TCNA) or the Ceramic Tile Institute of America (CTIOA). Beware of bargain, off-brand materials that lack recognized approval. |

Sheet membranes

Resembling thin rubber, pliable sheet-type membranes are sold in rolls, like fabric yardage. Marketed under several names, including CompoSeal, sheet membranes are widely available at tile and home improvement stores. These products are rolled out, adhered to the substrate with thinset, and then flattened with a linoleum roller. A sheet membrane is a good choice if you wish to apply an antifracture membrane but want to avoid the chemical odors produced by liquid and paste membranes. Just make sure that the particular material you buy is approved for use with ceramic tile.

Another type of sheet membrane is Schluter-DITRA uncoupling membrane. Like other membranes, it allows for normal horizontal movement of the substrate on a floor, which helps prevent cracks in the tile and grout. In the case of Schluter-DITRA, the “uncoupling” is a descriptive word for the way the membrane or cells on their orange waffle mat achieve the necessary separation between tile and substrate. However, Schluter- DITRA has the advantage that it is polyethylene, rather than a latex product, which makes it an important option for those with chemical sensitivities. The membrane is also installed with nonlatex modified thinset and may also be used for waterproofing.

Excerpted from Tiling Complete, 2nd Edition by Robin Nicholas and Michael Schweit.

Excerpted from Tiling Complete, 2nd Edition by Robin Nicholas and Michael Schweit.

Available at Amazon.com.