Easy Router Jig for Perfect Hinge Mortises

Get an accurate, consistent depth that perfectly fits the hinge leaves with this shopmade three-sided template.

Traditional butt hinges are hard to beat. Aside from their clean, beautiful look, they can deliver a lifetime of smooth, accurate action on the heaviest, most heavily used doors. For passage doors, cabinetry, and furniture, they have no match. With no built-in adjustment, however, butt hinges can a be a challenge to install.

Inset doors with butt hinges require precise fitting

Using butt hinges with inset doors, as I did recently on a run of kitchen cabinets, adds another level of difficulty to butt-hinge installation. The main challenge with inset doors is the way they are boxed in on all sides, allowing your eye to pick up the slightest differences in the reveals. Using butt hinges requires that you trim and mount your door perfectly the first time.

One of the keys to success is choosing high-quality butt hinges with accurate milling and little to no slop in the barrel. I get mine from Horton Brasses. Whitechapel and Brusso are other great brands, which I use for both cabinetry and stand-alone furniture.

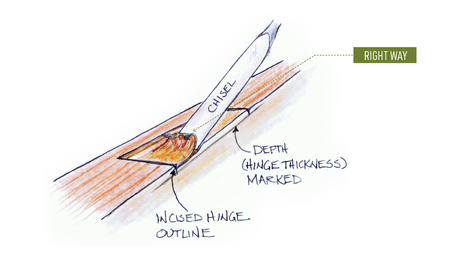

With hinges in hand, the next critical step is mortising them to a very accurate, consistent depth. You can chop and pare these shallow mortises by hand with chisels, but I find it to be much faster and easier with a shopmade router jig. The router ensures that the mortise depths are accurate and uniform, and the template ensures that the hinge leaves fit perfectly (after a minute of chisel work to square the corners).

A template that’s easy to make with common tools

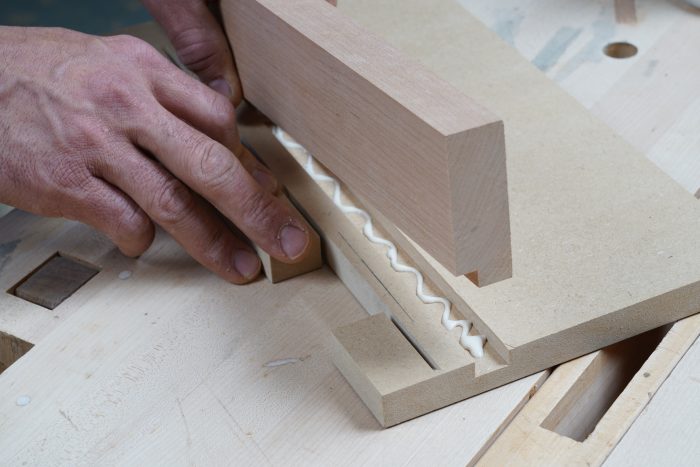

I make hinge-mortising jigs a variety of ways, including using my CNC router, but here’s a very simple design that’s easy to build with common tools, and works for doors and hinges of all sizes. It is basically a three-sided template that guides a straight, top-bearing bit in your router. The template is made on the tablesaw from an 8-in.-wide strip of 3/4-in. MDF. Start with a strip roughly twice as long as you need, to allow room for mistakes.

The fence is made from any other straight, flat material, roughly 3/4 in. thick.

The template has an open side, which means you don’t need a plunge router but can simple start the bit at full depth with any type of router.

In the photos below, the hinges were set in from the back side of the doors and face frames roughly 1/8 in. but you can design your jig for any hinge size or setback.

The first step is cutting an accurate opening in the template, to fit a hinge leaf exactly. My approach is outlined in the photos.

The next step is attaching the fence parallel with the opening in the template, at a precise distance from it, so you get the desired hinge setback. To lock the two parts parallel to each other, I run a dado on the back side of the template, and rabbet a hardwood fence to fit it. If you don’t have a dado set, you can cut the dado and rabbet in a series of passes with a standard blade.

Make a couple of test cuts to verify that the mortises fit the hinges and the setback is right, and then glue the hardwood fence into the dado. From there all you have to dial in is the bit depth on more test material, and then you can set any number of hinges with total confidence.

Making the hinge-mortising jig

The key steps are cutting an accurate opening in the template and then attaching the fence parallel to it, with the desired setback.

Using the jig

This template works with a standard top-bearing bit to rout accurate mortises for traditional butt hinges in frames and doors of all sizes.

—Stefan Straka builds cabinetry and furniture in Bellingham, Wash. Photos by Asa Christiana.

RELATED LINKS