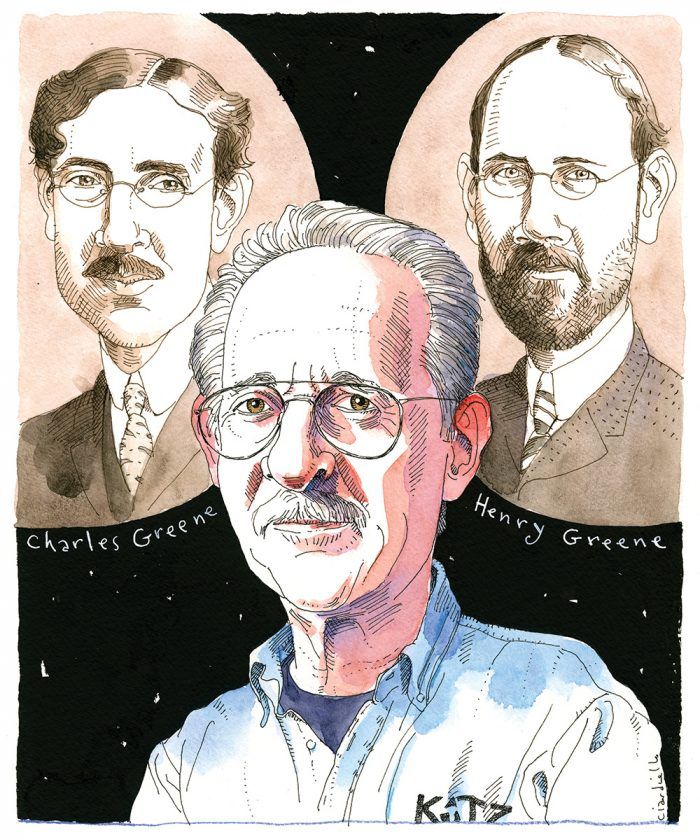

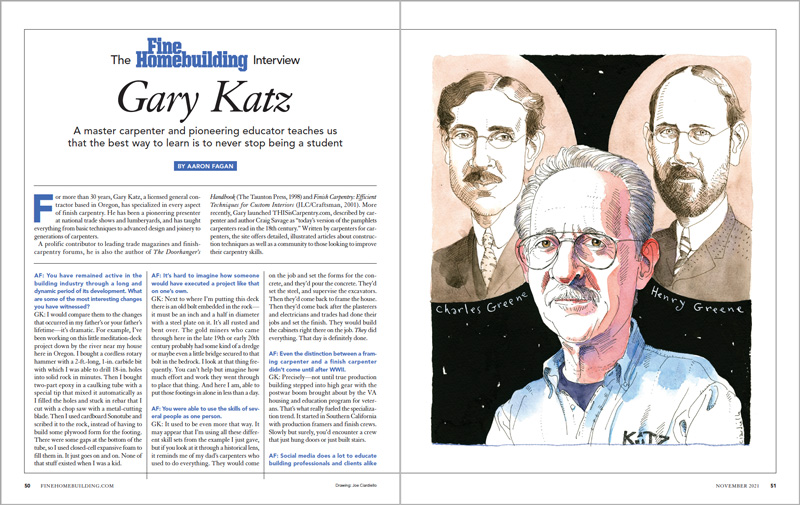

The Fine Homebuilding Interview: Gary Katz

A master carpenter and pioneering educator teaches us that the best way to learn is to never stop being a student.

Synopsis: Gary Katz is a finish-carpentry specialist, a prolific contributor to trade magazines and forums, and frequent presenter at trade shows and lumberyards. In this installment of the Fine Homebuilding Interview series by former FHB assoc. editor Aaron Fagan, Gary discusses the evolution of finish carpentry, the great figures that should not be forgotten, and how learning while doing is the best way to grow as a carpenter.

For more than 30 years, Gary Katz, a licensed general contractor based in Oregon, has specialized in every aspect of finish carpentry. He has been a pioneering presenter at national trade shows and lumberyards, and has taught everything from basic techniques to advanced design and joinery to generations of carpenters.

A prolific contributor to leading trade magazines and finish-carpentry forums, he is also the author of The Doorhanger’s Handbook (The Taunton Press, 1998) and Finish Carpentry: Efficient Techniques for Custom Interiors (JLC/Craftsman, 2001). More recently, Gary launched THISisCarpentry.com, described by carpenter and author Craig Savage as “today’s version of the pamphlets carpenters read in the 18th century.” Written by carpenters for carpenters, the site offers detailed, illustrated articles about construction techniques as well as a community to those looking to improve their carpentry skills.

AF: You have remained active in the building industry through a long and dynamic period of its development. What are some of the most interesting changes you have witnessed?

GK: I would compare them to the changes that occurred in my father’s or your father’s lifetime—it’s dramatic. For example, I’ve been working on this little meditation-deck project down by the river near my house here in Oregon. I bought a cordless rotary hammer with a 2-ft.-long, 1-in. carbide bit with which I was able to drill 18-in. holes into solid rock in minutes. Then I bought two-part epoxy in a caulking tube with a special tip that mixed it automatically as I filled the holes and stuck in rebar that I cut with a chop saw with a metal-cutting blade. Then I used cardboard Sonotube and scribed it to the rock, instead of having to build some plywood form for the footing. There were some gaps at the bottom of the tube, so I used closed-cell expansive foam to fill them in. It just goes on and on. None of that stuff existed when I was a kid.

AF: It’s hard to imagine how someone would have executed a project like that on one’s own.

GK: Next to where I’m putting this deck there is an old bolt embedded in the rock— it must be an inch and a half in diameter with a steel plate on it. It’s all rusted and bent over. The gold miners who came through here in the late 19th or early 20th century probably had some kind of a dredge or maybe even a little bridge secured to that bolt in the bedrock. I look at that thing frequently. You can’t help but imagine how much effort and work they went through to place that thing. And here I am, able to put those footings in alone in less than a day.

AF: You were able to use the skills of several people as one person.

GK: It used to be even more that way. It may appear that I’m using all these different skill sets from the example I just gave, but if you look at it through a historical lens, it reminds me of my dad’s carpenters who used to do everything. They would come on the job and set the forms for the concrete, and they’d pour the concrete. They’d set the steel, and supervise the excavators. Then they’d come back to frame the house. Then they’d come back after the plasterers and electricians and trades had done their jobs and set the finish. They would build the cabinets right there on the job. They did everything. That day is definitely done.

AF: Even the distinction between a framing carpenter and a finish carpenter didn’t come until after WWII.

GK: Precisely—not until true production building stepped into high gear with the postwar boom brought about by the VA housing and education program for veterans. That’s what really fueled the specialization trend. It started in Southern California with production framers and finish crews. Slowly but surely, you’d encounter a crew that just hung doors or just built stairs.

AF: Social media does a lot to educate building professionals and clients alike about what quality craftsmanship is. Can you talk about using education as part of a business model?

GK: I love the phrase “marketing through education.” Twenty years ago, I toyed around with that idea in various ways and it became the secret sauce of the Katz Roadshow, which was the only national, hands-on, peer-to-peer series of carpentry clinics, hosted at lumberyards all over the United States. We depended on marketing through education for our success. We convinced all these manufacturers to support the roadshow with what I thought at the time were big dollars. It cost tens of thousands of dollars for each sponsor to support our program, and we produced 20 to 30 events every year. People would come in for a whole day of serious, hands-on training with professionals. The companies supported it because they wanted to sell

their products.

Some of the lumberyards had been hesitant to bring our sponsors’ products in, which is one reason the shows were valuable to the manufacturers for what they call “pull through.” The idea is that if we used the products, the audience would realize the benefits and ask the lumberyard to bring those products into the store. Of course, many of the sponsors also wanted to support the show because their number-one problem was improper installation: improper flashing techniques or incompatible sealants and on and on. They wanted to get the word out on how to properly install their products. It spares both builders and manufacturers time, money, and damaged reputations.

All of it, the secret to the whole thing, was marketing through education. It stunned me to find myself in this position, keeping people in their seats for a whole day and simultaneously using a variety of different products without making it look like a sales thing. We stuck to real solid techniques while using a company’s products. It was a perfectly balanced program.

That’s what’s neat right now. I see it today—companies supporting people on Instagram who are really teaching other people serious stuff. And occasionally they use a product by that company, but they’re not focusing on supporting the company or product promotion, they are focusing on techniques, instruction, and education. These companies are seeing folks with 300,000 followers, and they want to get their products into the hands of those influencers. It’s remarkable what social media is doing for our trade…

To read the entire interview, please click the View PDF button below.

From Fine Homebuilding #303

RELATED LINKS