Which Pipe Fitting Do You Need?

Before you start your next home plumbing project, read this overview of drain-line connectors and flanges, water-line fittings, and more.

At a home center or plumbing supply store you’ll see an almost bewildering array of pipe fittings; the drain and vent fittings have the greatest variety. For a remodel job (especially a bathroom), don’t be surprised if you end up buying more than 20 different fittings to enable you to make all those twists and turns and changes in pipe size. A plumbing inspector will look for very specific fittings to perform certain tasks; if you don’t use the right fitting, you may have to tear out the job and repipe. Shown below are some of the most commonly used fittings. (Most of them are available for different sizes of pipes, which makes the variety even greater.)

Fittings that change direction

The terms elbow and bend are both used to name fittings that turn corners. A 90° elbow may be called a 1/4 bend, a 45° elbow is a 1⁄8 bend, and so on. Most commonly you will use 90° and 45° elbows with a hub (the wide female part of the fitting, into which pipe fits) on each end. A sanitary elbow makes a fairly tight turn, whereas a long-sweep elbow makes for smoother water flow. A street elbow has one male end, making it useful in tight situations. Bushings insert into a fitting hub to accept a smaller-size pipe. Elbows can also reduce in size. Couplings come in handy when you want to avoid notching framing members.

Connection fittings

These fittings are needed when joining drainpipes and vent pipes. Ts turn 90° corners, and Ys are angled at 45°. Ts may have one or more hubs that are reduced in size: A “3-3-2,” for instance, has two 3-in. openings and one 2-in. opening. Specialized fittings may have, for example, a fourth opening for a smaller-size pipe on one side. A low-heel vent 90 is often used for plumbing a toilet: Its top opening accepts a vent pipe.

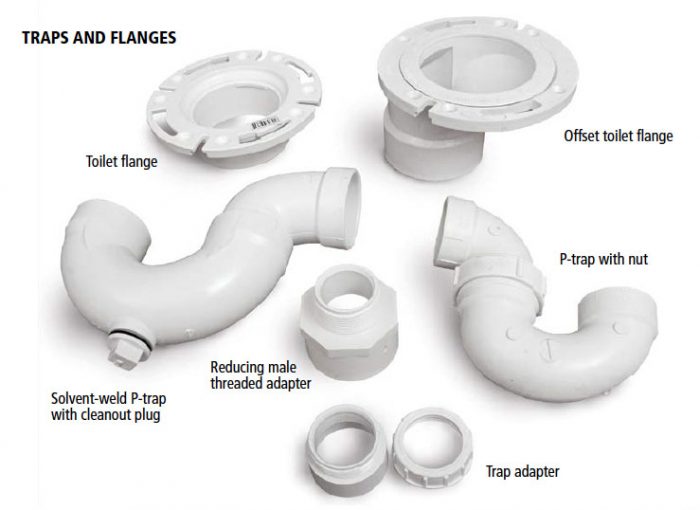

Traps and flanges

For a toilet or tub you will likely need to install a flange, usually after the flooring is finished. An offset flange moves the flange over a couple of inches. A trap that is inaccessible inside a wall or floor should be solvent-welded, meaning it is primed and cemented like a standard drain fitting. If the trap is reachable, you may choose to install one with a nut, so you can disassemble it for cleaning out. A trap adapter has male threads and an opening that accepts a 1 1⁄2-in. or 1 1⁄4-in. trap arm.

Flexible fittings

If plastic drain or vent pipes do not line up perfectly, it can be very difficult to make connections. Flexible fittings can make the job easier, and are often well worth their extra cost. These “rubber” fittings are actually made of flexible PVC, and so are usually considered a permanent solution. They connect firmly via hose clamps at each end. Consult with your building department; they may not allow these fittings to be installed inside walls or floors.

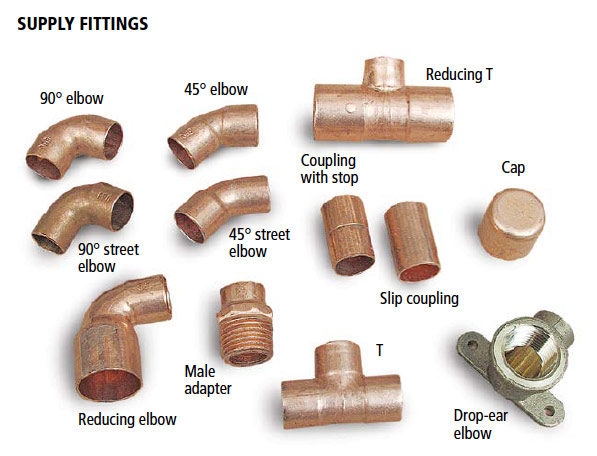

Supply fittings

Supply fittings are less numerous, but there are some variations that are very useful. In the photo, we show copper fittings; CPVC fittings are pretty much the same, and PEX pipe calls for fewer fittings. In addition to the standard 90° and 45° elbows, street elbows can make tight turns and minimize the number of joints you have to solder. A reducer T is most often used to change from 3⁄4-in. to 1⁄2-in. pipe. A coupling with a stop automatically positions the two pipe ends in the center of the fitting; a slip coupling is sometimes needed when tapping into an existing pipe to add new service. A drop-ear elbow is most often used when installing shower plumbing, but can also be used for stubbing out into the room.

Excerpted from Plumbing (The Taunton Press, 2016) by Steve Cory.