Building a Zero-Energy Home for Less

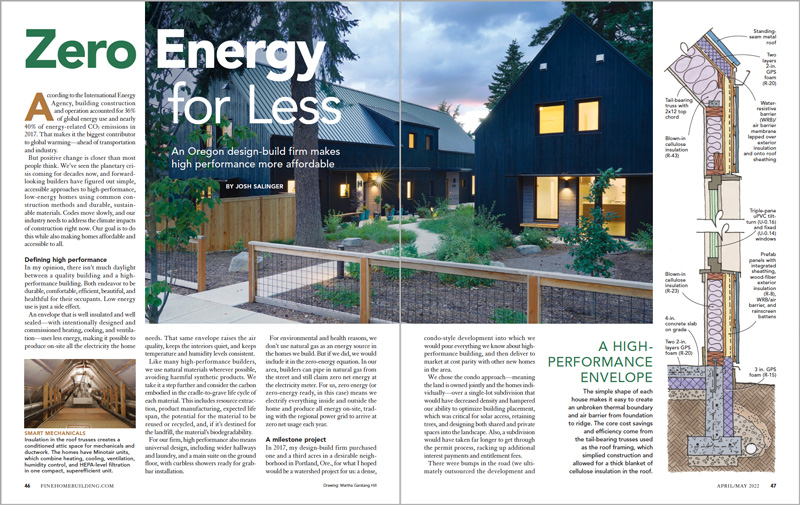

An Oregon design-build firm makes high performance more affordable.

Synopsis: Birdsmouth Design-Build CEO Josh Salinger shares how his firm’s goal is to create energy-efficient homes that are affordable and accessible to all. As an example, Sallinger describes the community of Going Street Commons, a condo-style project that Birdsmouth, alongside building partner Green Hammer, put together involving 11 high-performance, all-electric, zero-energy-ready homes. Factors such as choosing a basic house shape, assembling the roof with giant trusses, and being smart about the types of materials used all played a part in cutting costs and increasing efficiency.

According to the International Energy Agency, building construction and operation accounted for 36% of global energy use and nearly 40% of energy-related CO2 emissions in 2017. That makes it the biggest contributor to global warming—ahead of transportation and industry.

But positive change is closer than most people think. We’ve seen the planetary crisis coming for decades now, and forward-looking builders have figured out simple, accessible approaches to high-performance, low-energy homes using common construction methods and durable, sustainable materials. Codes move slowly, and our industry needs to address the climate impacts of construction right now. Our goal is to do this while also making homes affordable and accessible to all.

Defining high performance

In my opinion, there isn’t much daylight between a quality building and a high-performance building. Both endeavor to be durable, comfortable, efficient, beautiful, and healthful for their occupants. Low energy use is just a side effect.

An envelope that is well insulated and well sealed—with intentionally designed and commissioned heating, cooling, and ventilation—uses less energy, making it possible to produce on-site all the electricity the home needs. That same envelope raises the air quality, keeps the interiors quiet, and keeps temperature and humidity levels consistent.

Like many high-performance builders, we use natural materials wherever possible, avoiding harmful synthetic products. We take it a step further and consider the carbon embodied in the cradle-to-grave life cycle of each material. This includes resource extraction, product manufacturing, expected life span, the potential for the material to be reused or recycled, and, if it’s destined for the landfill, the material’s biodegradability.

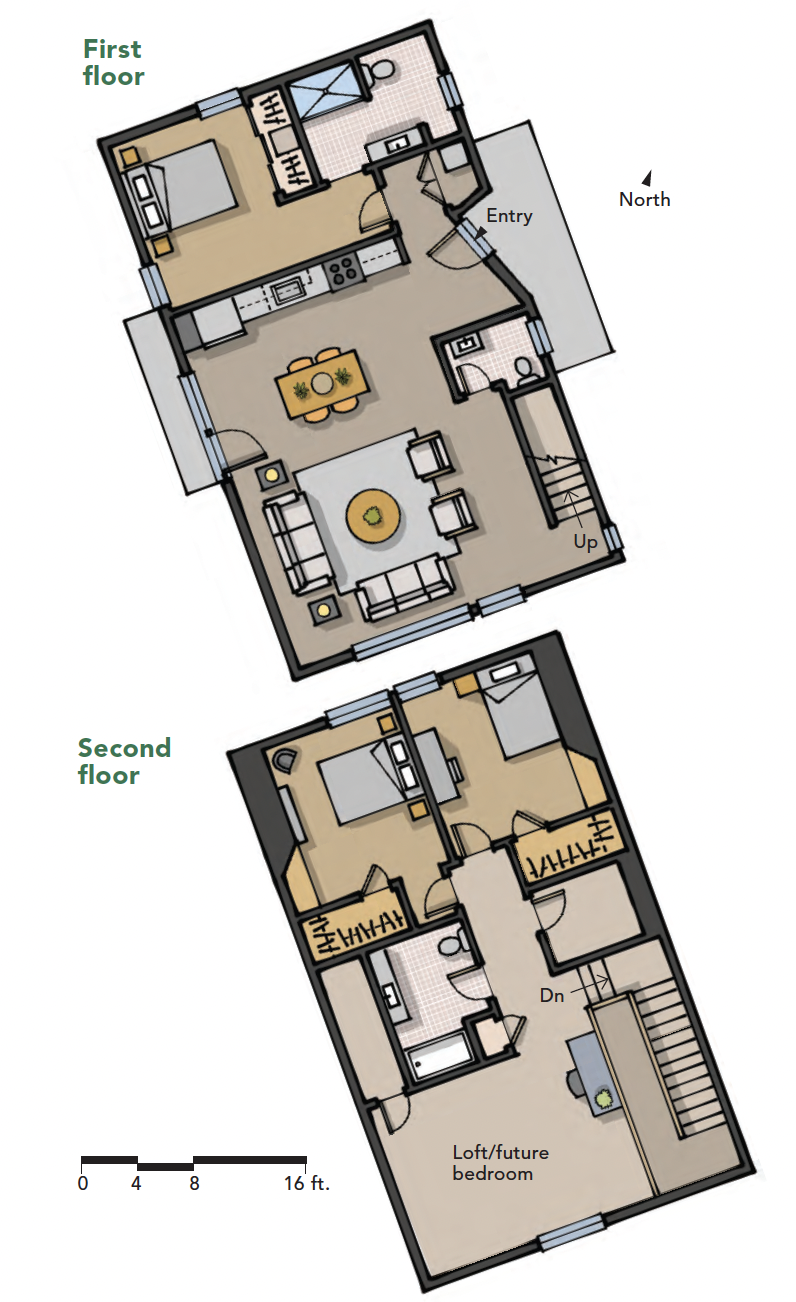

For our firm, high performance also means universal design, including wider hallways and laundry, and a main suite on the ground floor, with curbless showers ready for grab-bar installation.

For environmental and health reasons, we don’t use natural gas as an energy source in the homes we build. But if we did, we would include it in the zero-energy equation. In our area, builders can pipe in natural gas from the street and still claim zero net energy at the electricity meter. For us, zero energy (or zero-energy ready, in this case) means we electrify everything inside and outside the home and produce all energy on-site, trading with the regional power grid to arrive at zero net usage each year.

A milestone project

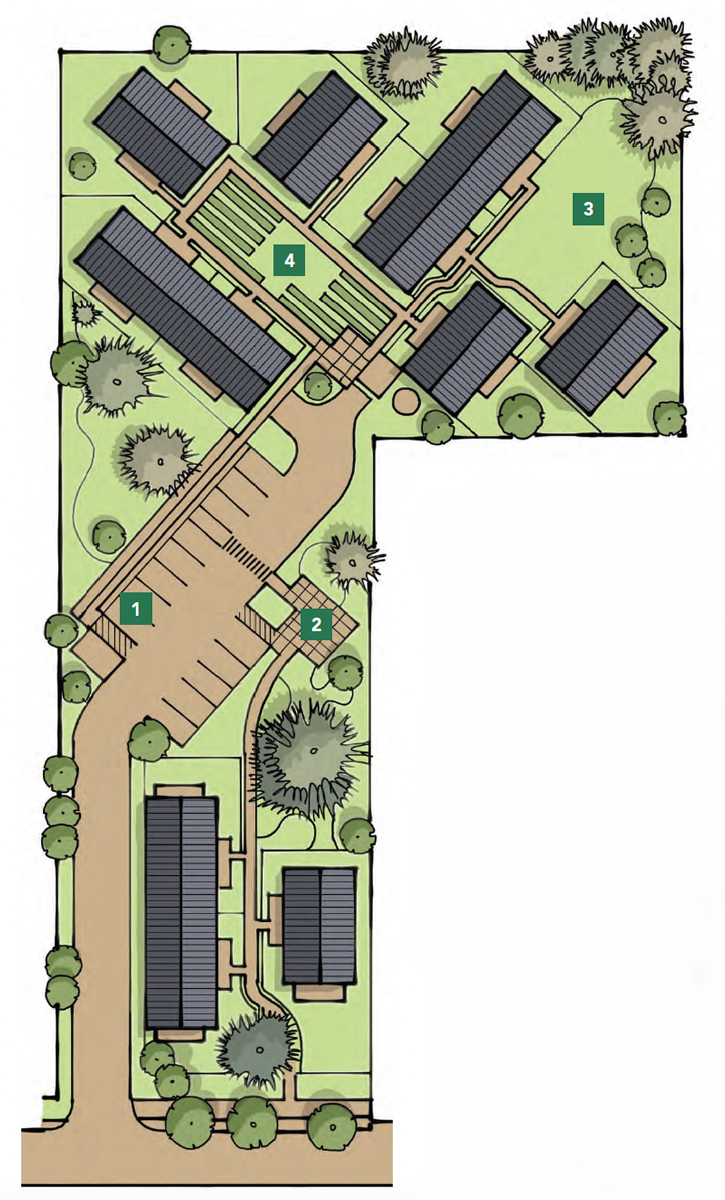

In 2017, my design-build firm purchased one and a third acres in a desirable neighborhood in Portland, Ore., for what I hoped would be a watershed project for us: a dense, condo-style development into which we would pour everything we know about high-performance building, and then deliver to market at cost parity with other new homes in the area.

We chose the condo approach—meaning the land is owned jointly and the homes individually—over a single-lot subdivision that would have decreased density and hampered our ability to optimize building placement, which was critical for solar access, retaining trees, and designing both shared and private spaces into the landscape. Also, a subdivision would have taken far longer to get through the permit process, racking up additional interest payments and entitlement fees.

There were bumps in the road (we ultimately outsourced the development and took on a build partner, the excellent Green Hammer, also based here in Portland, Ore.), but our core vision remained intact, and buyers are now moving into 11 high-performance, all-electric, zero-energy-ready homes at Going Street Commons, all priced to compete with similarly sized, standard-level homes in our market. We did this by reducing our typical cost per square foot for high-performance homes by almost 30%.

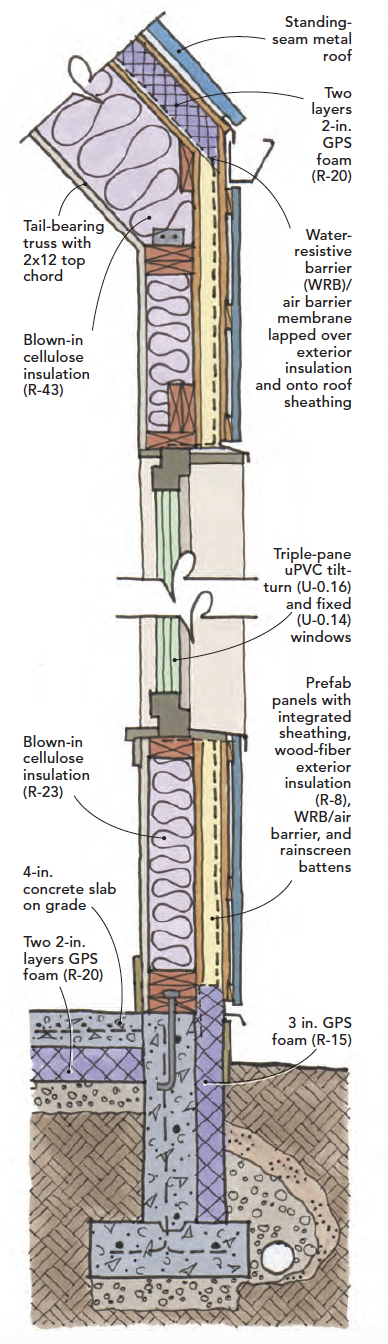

A High-Performance EnvelopeThe simple shape of each house makes it easy to create an unbroken thermal boundary and air barrier from foundation to ridge. The core cost savings and efficiency come from the tail-bearing trusses used as the roof framing, which simplified construction and allowed for a thick blanket of cellulose insulation in the roof.  |

Viewed from another angle, our mix of single-family and duplex dwellings cost just 10% more to build (build cost only, not including land) than custom, code-built homes in nearby neighborhoods with similar square footage and amenities. They come at a premium that will be paid off in 12 to 17 years with energy savings alone. Plus, there are the benefits of living in a more durable, comfortable, healthful home with unmatched air quality.

These homes are all-electric (no natural gas) and equipped for a sustainable future. Shared energy comes from an array of solar panels that will sit atop the carport, which has room for one car per family and is wired for electric-vehicle charging in the future. (Bike storage is also included on-site.) If residents choose to add PV panels to their solar-ready roofs, overall energy usage drops to net zero. A community garden adds another element of sustainability.

Despite the low comparative prices, we didn’t skimp on details or amenities. The homes feature vertical wood siding, standing-seam metal roofs, custom-fabricated steel entry awnings with integral gutters, Zola tilt-turn windows, kitchen islands, high-end finishes, and resilient native landscaping—all of which ensure the homes will be salable in the local market. While we viewed these premiums as necessary in our market, they might not be in others, offering an opportunity to reduce costs and prices even further.

Designed for performance and value

A simple house shape is most cost-effective; it makes construction quicker and easier. From an energy perspective, this simple shape offers a low surface-to-volume ratio and makes the envelope easier to air-seal and insulate. Also, the simple anatomy sends roof loads down the exterior walls into perimeter footings; just one interior footing and one glulam support beam below the second floor are required. To save on siding, windows, and other exterior work, we made the walls of our two-story building one-and-a-half stories tall. Not having a full second story means a lot less material to purchase and install.

In keeping with the spare Scandinavian style of the buildings, we eliminated roof overhangs. This made air-sealing easier by allowing us to tape the water-resistive barrier (WRB) seams up and over the roof. Overhangs have performance and durability advantages, to be sure, but we designed in mitigating elements that made us confident these buildings will be much more durable than their code-level counterparts. Those include large gutters; integrated flashings; less weather exposure with a one-and-a-half vs. a two-story building; a large, crosshatched rainscreen; a durable, tight WRB and air barrier (blower-door tests measured less than 0.6 ACH50); and quality control by the build team. The slab-on-grade foundation saved costs, and it is fully insulated to keep it at the ambient temperature of the interior.

Boxy shapes tend to look boring, which challenges designers to find ways to make them more compelling. To make our homes attractive, we went with vertical larch siding—an extremely durable product sourced and sawn in the Northwest—along with dark, standing-seam steel roofs. We added custom plate-steel awnings over the entryways, painted dark to go with the dark-stained siding. (The stain is water-based.)

From foundation to framing

For designers and builders here in the Pacific Northwest, the jury is in. A standard 2×6 (or 2×8) wall with plywood sheathing, a fully sealed air barrier, and exterior insulation has emerged as the go-to assembly. Over that goes a batten-type rainscreen and siding.

This wall assembly and the simple shape of the homes made it easier to incorporate panelized construction, which cost more up front but reduced labor costs. The wood-based panels were built in a factory and shipped via truck to the job site. They include sheathing, wood-fiber insulation, a WRB/air barrier (ProClima Solitex Mento 1000), a rainscreen, and rough openings flashed for doors and windows. The WRB/air barrier is taped to the adjacent panels and draped over the top edge of the panel and onto the top of the roof sheathing to continue the air barrier.

Using prefabricated wall panels promised to knock two months off the schedule, which would have saved us money in interest on the building loan. Development delays ultimately erased the potential savings, but our initial decision was still sound.

For the roof framing, we went with tail-bearing trusses that incorporate a 2×12 top chord, allowing for a thick blanket of cellulose insulation, therefore mitigating thermal bridges at the top-plate-to-wall connection—similar to how raised-heel trusses perform. Like all trusses, they reduce interior point loads, simplify construction, reduce labor, and lessen the amount of interior footings and large-format framing lumber needed.

By hanging the floor joists and creating a second floor before setting the trusses, we gave the framers a place to stand safely and work at waist height while setting them. After the first house or two, they were able to put up all the walls for a house in just six hours, and have the trusses installed and sheathed a week later.

The tail-bearing trusses created an additional benefit; if one thinks of a tail-bearing truss as a large letter “A,” the top triangle of the A is a conditioned space in which we could easily locate our mechanical systems and run ducts within the thermal envelope. The legs of the A, bearing on the top plate of the panelized wall, create a conditioned second floor. This radically simplified the thermal- and air-control layers and allowed us to efficiently build these homes with energy use and costs in mind.

It’s important to note that the current building market disrupted our projected costs, which were between $192 and $213 per sq. ft. based on 2017 prices. Still, the homes are at cost parity with other new homes in the area, which was always the goal.

Bottom line for a lower budget

You have to get a lot right to deliver high-performance, custom homes at a low premium. It takes experience and expertise, and success depends on several key factors.

Cutting costs and finding efficiencies to this degree requires a longer, much more comprehensive planning phase than most builders are used to, with a constant feedback loop between the design and build teams. It’s easier at a design-build firm, with designer, architect, and builder all in house and at the table during the planning stages.

If you do use a separate architect and builder, it’s important to choose them at the same time—before even getting pricing feedback—and be sure they are comfortable working collaboratively throughout

the project.

Photos by Asa Christiana.

From Fine Homebuilding #306

RELATED STORIES

- New Homes: 9 Things You Don’t Need, and 5 You Do

- Truss Options

- 6 Tips for Net-Zero House Design

- Energy-Smart HVAC

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Great Stuff Foam Cleaner

Nitrile Work Gloves

Disposable Suit

View Comments

I'll need to stop by and take a look. I lived on Going St when I was a kid - the neighborhood looks a lot better!

Energy efficiency is important, but so is design efficiency, which is lacking here. Who designs homes where the master bedroom's closet size per person is smaller than allocated for each child's bedroom? Or a powder room's door opening into a living room? Or a master bathroom with such an inefficient fixture layout? Is there even a laundry area? Where does the TV in the living room fit? This is an example of "penny wise pound foolish." Next time hire an architect.