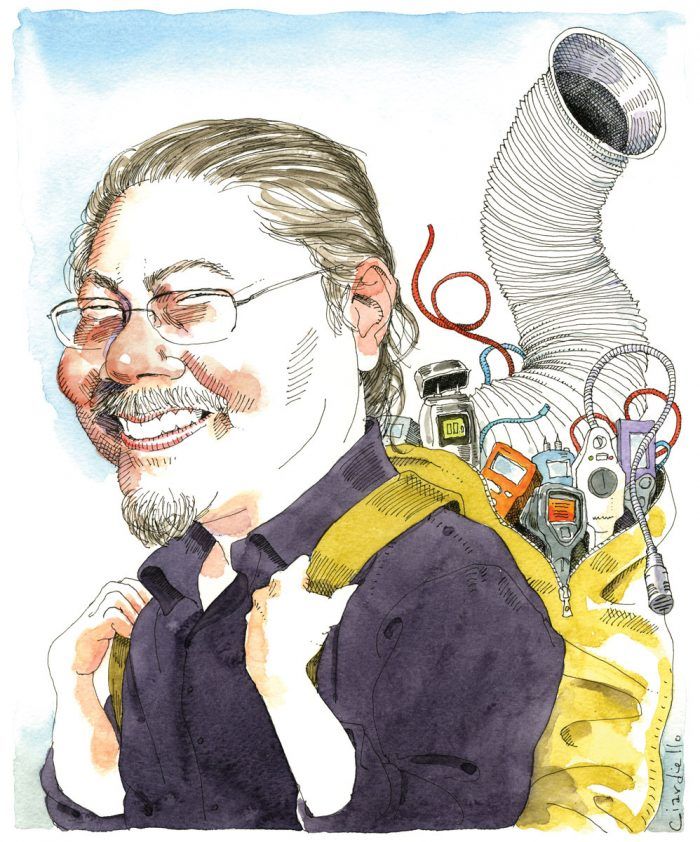

The FHB Interview: Kohta Ueno

This building scientist offers insight and trade tools for forensic investigation

Kohta Ueno is a senior associate at Building Science Corporation (BSC), a Massachusetts-based building enclosure/shell consulting company founded by Joseph Lstiburek. Ueno received an undergraduate degree in material science at the Massachusetts Institute of Technology and a master of applied science in civil engineering from the University of Waterloo. His work at BSC includes forensic field investigations of building failures and consulting work for new and retrofit construction in the design of building enclosures.

Under the Department of Energy’s Building America program, Ueno has conducted many field-study research projects on building science topics, including the moisture safety of unvented roofs with fibrous insulation, the hygrothermal behavior of basement wall insulation, the durability of double-stud wall assemblies, and the performance of minisplit heat pumps in cold climates, among many others. He is a dynamic speaker and frequent presenter at both academic and industry conferences and has published a variety of conference papers and articles.

AF: Is a lot of your day spent doing forensic investigations?

KU: BSC as a company pretty much made its bones on forensic investigations, both on the residential and the commercial side. We’ve done everything from airport control towers, to mansions with water leaks that nobody else can solve, to freezer warehouses with icicles growing out of the ceiling, to a house on Cape Cod where the SIP roof is falling in. It’s a wide mix of items. The forensics vary from more clear-cut enclosure or building-shell issues to investigations of massive humidity-control problems in multifamily housing—as in mold is growing on the furniture, the ducts up in the ceiling are condensing and dripping water, and they need to get some mold remediator in there to rip out the ceiling and fix it.

Based on this experience, we also work as consultants to builders, owners, architects, or contractors on the front end, while the building is still on paper, to try to avoid these problems. This is both residential and commercial work, but a lot of it ends up being a giant residence that the whole team is worried about “getting right,” with water leaks and dripping problems, and risks of angry clients, lawsuits, or other construction disasters.

AF: Those are major concerns. Have you observed a particular time period when the concentration of building failures seems to have been greatest? Some very strange engineered products emerged in the 1980s.

KU: I can’t say that I necessarily have a great cross-section of buildings over the ages, because a lot of the time, if a building is going to fail, it’s going to fail in a moderate amount of time. You can think of it as a “building childhood mortality” problem, perhaps. So if a 1970s house was completely screwed up, it’s either been ripped apart and redone by now, or it’s in the landfill, or it’s a sagging, abandoned, derelict wreck. If there’s any pattern that I can see—and this is both my personal experience as well as the literature—it’s that anytime you have a building boom (and anybody with a truck can slap a magnetic sign on the side and be a contractor), it signals a period of worse construction quality. Everybody’s trying to get in on the gold rush, and that’s when you’ll have problems. For instance, the huge Vancouver leaky condo crisis that began in the 1980s and lasted through to the early aughts was exactly that: another building boom where everybody was trying to get in.

To address what you’re saying about products, yes, we definitely see patterns where a given product is associated with a massive raft of failures. So you’ll see a whole bunch of those problems from buildings of that era. My boss and mentor, Joe Lstiburek, served as an expert witness dealing with the endemic EIFS (synthetic stucco) failures in the Carolinas in the 1990s, and he’s also done similar legal work on failures of hardboard siding and fire-retardant-treated plywood. And Joe also has spent plenty of time being an expert witness for other product manufacturers who have been wrongly accused of being the source of building failures.

AF: So when you’re on a new site, how do you approach forensic field investigations? I imagine you have information going into it, but is there a process—maybe a supersecret Kohta Ueno process that you go through?

KU: I don’t think there are any real secrets. The whole principle of engineering in general is to take a really complex problem and try to break it down into bite-sized chunks so you can determine cause and effect and figure out what is going on where. As far as going about doing a forensic investigation, we start by having a discussion with the client to understand what the problem is. Is this a straight-up rain-leakage issue? Is it a humidity-control problem? Is it a mold-growth problem? And if it’s a moisture problem, break it down a bit more. Is it just a rainwater-leakage issue, or is it something stranger than that? Air leakage, condensation, moisture driven through reservoir enclosures—all these kinds of things come up. When the client calls you and says, “Yeah, my building leaks water, but not on days when it’s raining,” you know that you might have a strange problem.

But getting back to the process, you want to know what kind of an investigation you’re doing, and you develop your ideas for tools and techniques to deal with it based on that. One piece of advice that Joe gave me early in my career is, when going to a building, “Always listen to the person who lives with it.” That could be the homeowner, the facility manager, or the person who’s running around with a mop dealing with all the leaks and stuff. They might not have the scientific solution, and they might not know why it’s happening, but they’ll typically have a very good idea of the patterns. The patterns are often critical for understanding what’s going on. Yes, it leaks when it rains. Or no, it happens on cold days, or cold days to warm days, or only on the south side of the building. All of those types of factors are vital clues you need to understand. Even if they can’t explain it, they have some critical information in there.

AF: They are your empirical resource.

KU: Absolutely. They have far more history than I do, when I’m just bouncing in on a plane flight for a day. In addition to that, amusingly but also depressingly, there are plenty of times when the facility manager, the person who’s living with the building, knows exactly what’s going on. And my report is literally saying the same thing that he or she is, but the powers that be need the out-of-town expert to say it. Perhaps that reflects the devaluing of knowledge from tradespeople, but that’s a whole separate discussion.

In terms of how I go about breaking down the problem, I’ll start by looking at the outside and the inside of the building—for instance, in a situation where there is a rain leak. Rain showing up on the interior is typically what’s driven the complaint. Then I’ll begin disassembling what’s there to understand how it was built. A lot of the time the drawings are a fiction compared to what actually was built on the ground. Often there’s no change order or sketch detail in the records to track what happened. So we have cases where we look at the details on the drawing and say, “Yeah, that should work.” Then we actually get to the site and discover the roofer came in before the wall guy and the roof ended up reverse-flashed due to a sequencing problem, and that’s why we’re draining a funnel into our wall. That kind of thing.

AF: Is there a tool kit for forensic work?

KU: Oh, man. This is one of my favorite things to geek out about. The thing is, there’s no absolute here. Joe Lstiburek has a Jedi Master fly-by-the-seat-of-your-pants attitude: He has told many a youngster who leans too much on instruments or simulations, “Luke … use the Force … Turn off the targeting computer.” In other words, look at the building and know it. By contrast, I am a Mr. Gadget technology geek. Remember the movie Up, with the overly enthusiastic Asian Boy Scout who has all this crap in his backpack? That’s me.

AF: So what is in your basic tool kit?

KU: I wrote a four-part series for Green Building Advisor on the tools of the trade that I use for these investigations. For example, infrared cameras have come such a long way, even in my career. Back in the early 2000s, they were a $5000 piece of equipment that you were terrified to take up into the attic for fear of dropping it, and you would only get this tiny, soda-straw, narrow field of view of an image. A few years ago I switched to a $300 accessory that plugs into the side of my iPhone, and it gives me better pictures than the old camera. And nowadays I’m using the standalone version of the same plug-in unit, mostly to avoid burning through my phone battery while taking infrared shots.

What does an infrared camera get you? It gets you surface temperature. That can tell you stuff like thermal bridging. It might tell you about moisture, depending on the circumstances. It might tell you about air leakage, especially when you combine it with a blower-door test. A blower door and other air-leakage equipment help, especially if I know that I have an air-leakage condensation problem or a summertime humidity problem. Another part of the tool kit is moisture meters, both the versions with pins and the contact (“capacitance-based”) versions.

Ultimately, being able to gather information, digest it, and put it together into a coherent picture is what’s critical. You can have all the gadgets you want, but if you don’t have the background to understand and digest what you’re observing, they’re meaningless.

AF: Have you ever had to make your own tools to measure or diagnose a problem? Was there ever a situation when there just wasn’t a tool in existence to do what you needed it to do?

KU: The state of the art is pretty darn good. There are a lot of instruments out there that give you an amazing amount of information. Here and there, you kind of jerry-rig something to make it work. For instance, there were times when I was using a Duct Blaster duct-leak testing fan as a powered flow hood, and I made something out of Rubbermaid containers and Sonotube to do these measurements. But a couple of years later Energy Conservatory came up with a much better system, and that thing went in the trash.

AF: Are there areas of building science that are the most interesting to you right now, either for your own research or that you’re learning a lot from?

KU: Many of the journal papers that I have presented or co-presented at conferences are typically work that I’ve been doing on building-enclosure or building-shell monitoring. We basically build a bunch of test walls, throw in a bunch of instruments, measure them for a couple of years, and see how these things behave side by side.

Our most recent big one was unvented roofs with various fibrous, dense-pack insulations. As background, doing an unvented roof with no ventilation channels has been in the building code since the late 1990s. If you shoot it with spray foam, it’s a moisture-safe (or moisture-safe-enough) roof that has an established track record. It’s a known quantity. However, there are the cellulose guys who are saying, “Look, we can use this lower-cost, more environmentally friendly material to dense-pack your roof and have the same result.” And we wanted to investigate that a little bit more.

And because there are all these different technologies now—those vapor barriers that can open up when they get wet, variable-permeance vapor retarders—we looked at something called the diffusion vent. Moisture in these roof assemblies typically accumulates up at the ridge. Can you basically let it dry out in a “localized manner” at the ridge, through a “vapor-open” but waterproof detail?

The takeaway from that research was that, yes, they can work, but they are risky. In our research, we ran our test roofs through varying conditions over three winters, and it pretty much failed in the second winter. We grew mold inside the roof. Then we had the insulator come back and repack it. And in the third winter, it worked fine. So now the takeaway is, yes, you can get them to work if you have two attempts at it or if you get it right the first time. But it’s a risky thing to say we would recommend adding this to the building code, because if you add something to the building code, you have to anticipate that it might be built by the worst possible contractors with the cheapest possible materials with the worst quality control. That’s not a recipe for success.

AF: What else have you been working on recently? Can you tell me more about the humidity-control problems in multifamily housing that you mentioned?

KU: Over the past few years, I’ve been investigating many multifamily buildings and hotels up and down the East Coast that have been growing mold and experiencing moisture problems during the summer—typically new construction or newly renovated buildings. It is bad enough that the cooling ductwork in the ceiling space has condensation all over it, and it drips down through the ceiling. The owners and builders are convinced at first that “we’re building these things too tight,” but if you just look at the weather or dewpoint data, it’s obviously moisture from outside air and a lack of dehumidification in the summer.

These problems create a perfect storm: When you combine better-insulated enclosures, good windows, high-efficiency HVAC equipment that doesn’t dehumidify as well as older systems, and oversized units that don’t run as much of the time, buildings that used to work are tipped over the edge into moisture-problem territory. This is made worse when the ventilation system is only a bunch of exhaust fans and relies on air leaking in from outside—after all, the building isn’t shrinking when you send air out of it. That outside air will put a giant humidity load wherever it leaks into

the building.

AF: How did you get into building science in the first place?

KU: As far as I know, no kids that I’ve met have a lifetime aspiration to become a building scientist. Everybody gets into the field some completely bass-ackwards way once they find out that this field exists. So as a first clarification, no, I was not bitten by a radioactive Joe Lstiburek.

The actual story: I was burned out after college. The thing that I actually enjoyed the most during my undergrad career was working on small projects around our living group. And for a while after college I hung up my shingle as a small contractor, just doing messy little kitchen and bathroom remodels for friends—cabinetry, plumbing, dropping in the outlets, tilework, and all that.

I learned a heck of a lot, but I’m a terrible businessman and ended up living in my parents’ basement. While living there, I ended up watching an episode of Nova on PBS, and one of the talking heads on that show was Joe Lstiburek. He was talking about how he went about diagnosing the sick building syndrome at the Registry of Motor Vehicles in Boston. I thought that sounded like some cool stuff. I cold-called BSC. Betsy Pettit answered the phone, and with an incredible stroke of luck, they were looking for an entry-level person right there and then. I was incredibly fortunate.

The other piece that’s fortunate, of course, is that the ideal candidate for a building scientist is somebody who both understands buildings and construction and has a solid grounding in engineering—someone who’s not afraid of getting a little math thrown at them. It is, once again, incredible serendipity that I lucked into that combination. That’s my origin story.

Drawing: Joe Ciardiello

From Fine Homebuilding #307

RELATED STORIES

- Moisture Issues with SIPS and How to Avoid Them

- The Fine Homebuilding Interview: Christine Williamson

- Contemplating Building Science Education

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Code Check 10th Edition: An Illustrated Guide to Building a Safe House

A Field Guide to American Houses

All New Kitchen Ideas that Work