Sheathing and Insulation in One

NovaCore Thermal Insulated Sheathing from LP could make wall assemblies simpler by combining OSB sheathing with XPS insulation.

For decades now, high-performance builders have added a layer of exterior insulation to their wall assemblies to slow thermal bridging and give exterior walls a boost of added R-value. The continuous insulation layer is often installed over the sheathing, adding time and complexity to a build. It’s also possible to install rigid insulation instead of OSB or plywood sheathing, with the resulting structural challenges of installing siding, trim, and windows over foam. And without the racking- and uplift-resistance provided by solid sheathing, a home’s lost strength must be made up for in other ways.

LP’s recently introduced NovaCore Thermal Insulated Sheathing solves these issues by combining sheathing with continuous insulation for simpler installation with no structural shortcomings. The insulated sheathing panels combine a 7/16-in.-thick OSB sheathing layer with a 1-in.-thick layer of XPS insulation. This is similar to Huber’s insulating Zip R-Sheathing, which has between 1 in. and 2-1/2 in. of polyisocyanurate insulation as well as a built-in water-resistive barrier (WRB). NovaCore’s maker claims that unlike a polyiso, which loses some of its R-value in extreme cold (a phenomenon described as “thermal drift” by building scientists), the XPS layer in NovaCore maintains R-5 in the coldest winter temperatures. Because NovaCore doesn’t have a built-in WRB, another water-shedding layer is needed.

The panels can be installed both vertically and horizontally and are fastened with 3-in. by 0.131-in.-diameter, full-round-head framing nails. The manufacturer says the panel will be available in 8-ft., 9-ft. and 10-ft. lengths in late 2022. At the time of writing, there is no word yet on pricing.

RELATED STORIES

- Six Proven Ways to Built Energy-Smart Walls

- One-Piece Foundation Insulation and Finish System

- Modern Modular Cladding System

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

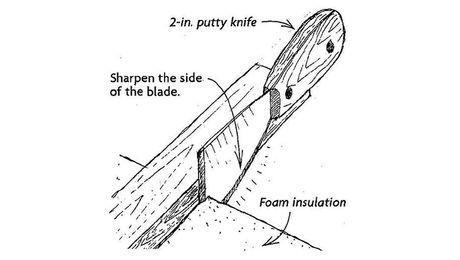

Insulation Knife

Caulking Gun

Respirator Mask

View Comments

Does LP reveal the blowing agent for their XPS (Extruded PolyStyrene)? At least in the past, many versions of XPS have used blowing agents with a significant Green House Gas (GHG) potential. Some manufacturers have been unwilling to reveal their blowing agent.

Your mileage may vary, but using insulation which can outgas a GHG takes away some, if not all of the many benefits of Continuous Exterior Insulation. There's a good argument that Expanded PolyStyrene (EPS) which uses steam as a blowing agent might be a better choice. One downside is that EPS isn't generally as strong as XPS.

The NovaCore website mentions "zero ozone depletion potential," but that's different than Global Warming Potential. NovaCore uses Owens Corning FOAMULAR

NGX, "with an innovative blowing agent blend that delivers 90% reduction in Global Warming Potential." The site notes that GWP impact is measured over a 100-year time horizon, and is measured relative to the original FOAMULAR® blowing agent formulation.