Choosing the Right Construction Tape for the Job

Keeping out air and water for the long haul requires using seam and flashing tape the right way.

Synopsis: Construction tape is a key part of residential construction, used to cover the seams of a water-resistive barrier or flash a window and prevent infiltration of air and water. As time has gone on, advancements in tape technology mean products adhere better and are more effective. Despite these advancements, there are still ways to incorrectly use adhesive tapes. Builder and energy auditor Randy Williams goes over the anatomy of construction tape and the importance of proper use.

Whether used for covering the seams of a water-resistive barrier, flashing a window, or making an air barrier continuous, construction tapes have become a key part of residential construction. My first experience using a construction tape was taping housewrap seams and window flanges 20 years ago. That tape, which is still in use today and looks like packing tape you’d use for shipping a box, didn’t stick so well.

Newer tapes adhere better and do far more than just seal housewrap. But despite advancements in tape technology, you can still use tape incorrectly or use the wrong tape for the job. My work as a high-performance builder and energy consultant in one of the country’s coldest areas requires that I use the right tape the right way. I’ve even done my own research to ensure my clients’ homes perform the way they should.

Common applications

Keeping water out of our assemblies is one of the most common ways to use construction tape. Taping the seams of a mechanically attached water-resistive barrier (WRB), like Tyvek, or a factory-applied WRB, such as the one incorporated into Zip System sheathing, can create an effective water-shedding assembly as long as the tape is applied correctly. We can also use tapes to protect window and door rough openings from water damage; to water-seal penetrations through wall assemblies, as with dryer and bath vents; and to seal a foundation or roof to exterior walls. Tapes used for water management often also keep air from moving through assemblies.

I always try to use one manufacturer’s products on an assembly. For example, when using Tyvek housewraps, I use Tyvek’s tape. When I use Siga’s air- and vapor-control membranes, I use Siga tape. When you stick with one maker’s products, you can be more confident that they’ve been tested as a system and should perform as intended, assuming you follow the manufacturer’s instructions.

Compatible surfaces

Unlike in the old days, modern tapes adhere to a wider variety of construction materials, including engineered and solid wood, rigid insulation (e.g., XPS, EPS, and polyiso), plastics, PVC and fiberglass window flanges, metal, glass, and concrete. For reliable adhesion, some tapes require a primer on OSB or concrete for a better bond. You have to check the manufacturer’s data sheets for specific requirements.

How well a tape sticks to a surface is based on several factors. Whether the surface is smooth or rough is one of the biggest factors, with smooth surfaces providing the best adhesion. The porosity of the surface matters as well. Generally speaking, surfaces that are less porous hold tape better than porous ones. The viscosity of the glue on the tape affects how it contacts the surface, which in turn affects adhesion. It’s important to remember that the viscosity may change with temperature, and tape that worked well with the temperature and humidity conditions one day may be less reliable the next. Some tapes “creep,” or slide off surfaces when temperatures are too high, and other tapes don’t stick reliably in low temperatures. Another factor is how clean or dry the surface is. Dust, pollen, and debris should always be removed. Some tapes work on damp surfaces, while others require the surface to be completely dry. In all cases, check with the manufacturer for guidance.

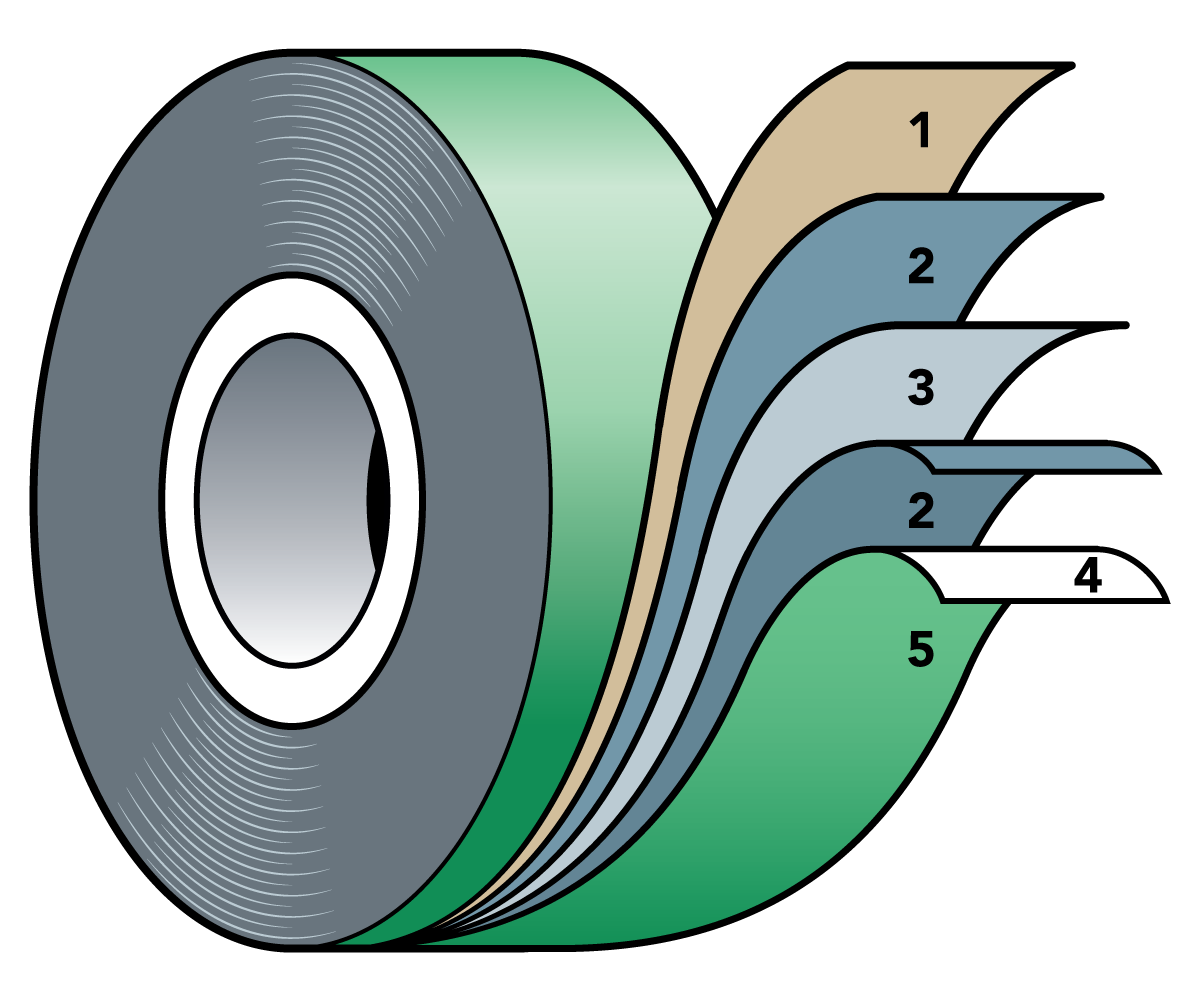

Another factor in a tape’s performance is the material the adhesive is applied to that creates the tape. This “support surface” (or “backing”) can vary; for instance, a UV-resistant support surface can be exposed to sunlight and is often used in an open-cladding system. Other tapes have a reinforcing band running through them to improve durability and strength, and still others have a backing that can be greatly deformed, as with Zip Stretch Tape. Construction tapes also come in several different widths. Avoid a one-size-fits-all mentality, and choose tape composition and width by individual application.

Tape manufacturers often have a list of materials you shouldn’t cover with their products. For instance, Siga says you shouldn’t use its Wigluv tape with GE’s Silicone 2 Window & Door, Henry’s 212 All Purpose Crystal Clear, or Tremco’s Spectrem 2 sealants. Before using a particular tape, check with the manufacturer for potential compatibility problems.

Release liner options

The presence or absence of a release liner can slow or speed installation. Certain tapes, such as Zip’s Flashing Tape, can be ordered with or without a release liner. Tyvek’s Seam Tape does not have a liner, so the tape’s adhesive is in direct contact with the tape’s backing. Tapes without a liner are faster to install, but the result can be messy if installers aren’t careful.

With tapes that have a paper or plastic liner, the liner must be peeled off before the tape will adhere. Pulling the release paper takes more time, but there’s less risk of wasted tape and sloppy installation. Some tapes have a split liner, so a portion of the liner can be removed at a time; this simplifies taping corners and allows the tape to be integrated with other water-shedding materials after it is initially installed.

Split liners also make it easier to work with very wide tapes, such as 3M’s 12-in.-wide 8067 flashing tape, which has an uneven split at 2 in. from one side and 10 in. from the other. A newer type of release liner has been produced by Rothoblaas, whose tape called Smart Band can be split anywhere on the liner. Simply create a nick and the release liner can be peeled apart, which can be convenient in certain places.

From roll to building

I use a couple of different methods to apply tape from a roll. If there is no release liner, I unroll short lengths of the tape, smoothing with my hand as I move along. When I get to the end of the taped section, I cut the tape and then roll the newly taped section with a J-roller.

If there is a release liner on the tape, I choose one of two methods depending on the length of the taped section. If it’s about 10 ft. or less, I cut the tape to length, peel the release liner in about 3-ft. sections, and apply the tape separate from the roll. For longer sections, I use roughly the same method, but I pull the tape right from the roll, removing the release paper in 3-ft. sections as I tape. This method results in fewer seams and less chance for leaks.

Tape keeps getting better

Construction tapes continue to improve. They’ve simplified how we address air-sealing details and help to keep our assemblies dry. Understanding where, when, why, and how to use a specific tape requires some research. Most manufacturers have the necessary information on their websites, and many have trained representatives to answer questions. If you choose the right product, follow the instructions, and pay attention to the weather conditions, you will greatly increase your chances of success.

Low-temp tape test Recently, we experienced problems with a high-performance tape bonding correctly in cold temperatures. At 14°F, the tape was applied at the bottom end of the manufacturer’s recommended application temperature. To determine if the problem was the tape or something we were doing wrong, I decided to apply several different tapes on different surfaces during cold weather. Some worked better than others; as it turned out, the tape we were using was one of the best overall performers. Many tape manufacturers suggest that their tapes can be applied during cold weather. All the acrylic tapes have low-temperature applications listed at 14°F or colder; Protecto Wrap’s Super Stick, which is a butyl tape, has a listed low-temperature application of –20°F. (But believe me when I say that –20°F is not a temperature in which to be applying tape.) I recently performed a new cold-weather tape test to see if a single tape’s performance was affected by low temps. This test was done on a dozen different tapes applied to several different surfaces with temperatures around 20°F. None of the tested tapes performed as well in the lower temperature as they did when temperatures were more moderate. I expected to have difficulties pulling the tapes off several of the surfaces they were applied to, the hardest being standard plywood. None were difficult to remove, and I pulled off a few with little effort. Overall, if you’re using pressure-sensitive adhesives in cold or very cold temps, I recommend using the acrylic-based tapes, such as Pro Clima’s Tescon Vanna, Siga’s Wigluv, 3M’s 8067, or Zip System’s Flashing Tape. The butyl Super Stick also performed well. I used to choose the tape based on the budget of the build, but I no longer do that. Tapes are designed to keep something in or out. Often that’s water, which is the number-one killer of buildings. In my opinion, tapes are not the place to save money. Install the best tape you can, perform your own backyard testing, and find the system that works best for you. |

Randy Williams is a builder and energy auditor in Grand Rapids, Minn.

Photos, except where noted: Matthew Millham

From Fine Homebuilding #309

RELATED STORIES