Podcast 475: Material Delivery, End Dams on Head Flashing, and Sealing Barbara’s Barn

Andrew, Ian, and Patrick hear from listeners about exposed sheathing and setting up for a blower-door test before taking listener questions about delivery subcontractors, how to make a head flashing, and sealing a post-frame building at grade.

Follow the Fine Homebuilding Podcast on your favorite app. Subscribe now and don’t miss an episode:

|

Help us make better episodes and enter for a chance to win an FHB Podcast T-shirt:

www.finehomebuilding.com/podcastsurvey

Carson shares thoughts on design software and exposed Zip sheathing. Mike Guertin explains how to do blower-door testing with whole-house ventilation. Dave writes in about replacing fossil-fuel boilers with electric-powered versions. Alex asks if anyone has experience with Renorun, a building-material delivery company. James wonders how to detail end dams on head flashings. Barbara—yes, that Barbara—asks how she should seal her post-frame barn for greater comfort and to keep out pests.

Editor Updates:

- Ian’s landscaping

- Andrew’s upstairs flooring, Connecticut visit

- Jeff’s miscellaneous yardwork

- Patrick’s table and sawhorse cabinet

|

|

|

|

Listener Feedback 1:

Carson from Oregon writes: Hi FHB crew, thanks again for running this great podcast! In regards to the question posed in episode 465 about Zip panel exposure, I can offer my own experience. Zip panels are rated for 180 days of exposure according to Huber, and specifically must be covered by finished siding before then. Their recommended fix to me over email for this was to cover the zip in housewrap. My builder went beyond this date sadly, and ended up covering all of the Zip in Tyvek. It’s a bit of a Frankenstein build at that point, as the windows still drain to the Zip, which is then covered by Tyvek. I suppose it’s probably fine as water can hopefully still drain behind the Tyvek thanks to a mesh rainscreen detail. Huber made no mention of air sealing potential after 180 days, I just hope it holds up long term. Questions about the details to Huber were just referred to the housewrap manufacturer, who of course has no Zip-Tyvek detailing so I wouldn’t count on much warranty coverage for any of this.

Is there a recommended CAD program for landscape drawing? Or is that SketchUp as well? Sketchup 7 is a free version that used to be called SketchUp make and you can still download it, but is not advertised. It is old, but may be fine for basic needs, or at least was fine for my cabinetry planning needs. Blender is another free option, though it is designed for studio work and has a far higher learning curve. Thanks for the regular insights

Related Links:

Listener Feedback 2:

Mike Guertin writes: Hi Ian, In last week’s FHB Podcast (episode 471) you discussed the results of the blower door test on your house. I think you noted that the person doing the test had you leave the intake and exhaust vents for the HRV open and unsealed. This may be a mistake depending on the protocol you asked the tester to use to evaluate the house. The commonly used IRC and ANSI/RESNET/ICC 380 blower door test requirements call for the intake and exhaust ports of any ‘continuous ventilation system’ to be sealed at the exterior penetrations. That would include an ERV/HRV, exhaust-only fan (like a bath fan) or a supply-only fan delivering fresh air to a ducted HVAC system used for continuous ventilation, or balanced intake/exhaust system without energy recovery.

JLC just posted an article by Randy Williams that outlines all the prep that should be done before a blower door test. See the ‘Dampers and Vents‘ section where he describes the requirements for ventilation systems. I’ll bet if those ports had been sealed the test results would have been under 0.5 ACH. It’s amazing how much air can move through a couple of 6 in. ducts. So you likely have ‘lower than Passive House’ air tightness.

Well done.

Mike

Related Links:

Listener Feedback 3:

Dave writes: Hi Patrick and folks! I just listened to the most recent FHB podcast – I’m pretty sure it was enlightening, fun, and worth my time, as ever! Since you’re transitioning from Fine Air-Sealing to Fine Furnace Replacement I thought I would write in with my experience, limited though it is, in these matters. Because what would be more helpful than yet another voice in the din?

Firstly, I applaud everyone’s efforts to get the nation’s homes off of fossil fuels. This is vital work and needs to proceed faster than we can possibly manage. Secondly, I think we all desperately wish that air-to-water heat pumps were where we needed them to be in terms of being powerful enough to work as a plug-and-play replacement for oil and gas boilers, especially for our coldest climates. From what I understand, these heat pumps require low temp emitters, which gets into total baseboard replacement with modern radiators which are either elegant or hideous depending on your house and taste. Some of these can work for cooling, too. I don’t know anyone yet that loves their baseboard heaters and many are very happy to consider removing them, but quickly change their mind when they see the price tag for this work.

Lastly, the fossil fuel alternative to gas and oil boilers is pellet boilers. These can handle high temp water distribution for baseboard heat. Not everywhere has a robust system for pellet delivery, but it’s getting better, I think. Around my area, there’s a few companies that deliver them in large awesome trucks that vacuum pump bulk pellets into site-built hoppers that provide months’ worth of heat and hot water. This seems infinitely preferable to the delivery of one or a dozen pallets of bagged pellets. How annoying! All those bags!

Some Vermontier-than-average clients of mine balk at the industrial infrastructure required to produce pellets, to which I counter, as compared to what? Oil? Propane?

Thanks as ever for all the work you are doing!

Question 1: Is RenoRun a good option for getting job-site materials delivered?

Alex writes: Has anyone heard about this company before? RenoRun Looks like they are only based in a few cities but for $5 more than the cost of a Home Depot truck you can have someone else deliver job-site materials? Seems like the kind of company that is backed by venture capital and will eventually flop, but that is just my oblique observation.

Related Link:

Question 2: Ian asks about tropical “Apocalypse Now” type of humidity and dehumidifiers.

Related Links:

- Dedicated Dehumidification

- Where is the Humidity Going?

- Measuring the Efficiency of a Room Dehumidifier

- The Pros and Cons of Running a Dehumidifier

Question 3: How do I detail end dams on head flashings?

James from GBA writes: Hello again! Zone 2A, new build. Nail-fin windows in plane with the sheathing/WRB. ½” rainscreen, with 5/4″ live edge siding and 3x trim (mounted to RS). Steel head flashings on *both* the windows *and* the trim. 3 questions:

1) With respect to the flashing on the head-trim: How far should it project? General rule for windows is 1/4″ I think? But I’ve heard that for trim, when the window below has a metal drip cap, zero projection is okay — because any water that runs down the face of the trim (and wicks underneath it) will just land on the *window’s* head flashing.

2) Does a 5/16″ L “drip leg” plus a 1/4″ L kickout sound okay? Making these elements as big as Hammer & Hand (and FHB!) recommends covers up a lot of the window frame’s head. Looks bad on the double hungs (I made a prototype).

3) My head flashings will have end dams, and I’ve seen builders like Malcolm Taylor here suggest that you should cut small notches in the head casing (trim) to allow it to be lowered over your end dams (to the normal ¼” gap b/w trim and window frame). What’s the point of having a greater-than-1/4” H end dam, if you’re blocking off the top ¼” of it? Why not just make it ¼” H?

Thanks James!

Related Links:

- Making Head Flashing

- Window and Door Flashing Guide

- Part 3: Flash a Nail-Fin Window in a Wall with Zip System Sheathing

Question 4: How do I seal and insulate existing corrugated steel exterior walls?

Barbara writes: Hello Podcast! I’ve made up my mind to renovate my shed this year. My shed is nice and big, 30’x35’. But it’s kind of like an airplane hangar, with two walls of cannonball track doors that can never be made to keep out a mouse or a bird. So I want to build a 12’x14’ room in the northeast corner. The two interior walls will be made of old sliding glass doors I’ve been saving. The indoor roof will be made of salvaged ProPanel, the same stuff the building is made of, pitched enough that wrens can’t build a nest on it. I will move my house mini split to this space and upgrade my house one to a newer, quieter model. Then I’ll be able to set up a laser cutter and a 3D printer or other tools that require humidity control.

I have two questions about this.

1. What would you use to seal and insulate the existing corrugated steel exterior walls?

2. What do I buy to build an airtight plate glass wall?

My shed used to have the other corner insulated with fiberglass with particleboard for interior walls and a big wall of particleboard cabinets. When I came back to this abandoned property about 20 years ago, I removed all of that. The trauma of that experience is probably why I never use processed wood sheet goods of any kind. The main tool for the job was a flat bladed shovel. For stripping walls. Never again.

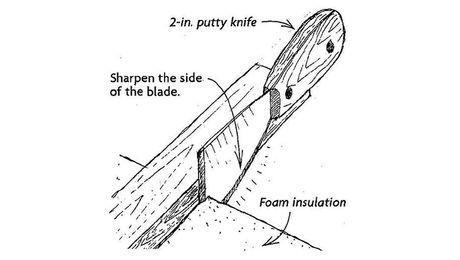

The space between the bottom plate and the high ribs of the panels on those two walls were stopped up with rubber plugs. (See photo) Not airtight. There is a sort of lip on the bottom of the slab that the panels sit on. But they are pretty much touching the ground. I need to grade around that uphill side because soil has built up over the years and it could be taken down a lot. (See photo) Even after I do that the bottom mustn’t wick water up from the outside. My bottom plates are in good shape because they’ve been able to dry out this whole time. (See photo) If I build a wall and rot them out, I’ll never forgive myself.

|

|

I am absolutely certain there is a good vapor barrier under this slab. My father built this shed and he has never poured a slab without visqueen and wire mesh. I bet his boat ramps have visqueen. I have watched enough mouse trap YouTube to know that caulk is the best barrier to mice. Bet it works on insects too. What if I just squeeze about 1/4 cup of Big Stretch in those high ribs behind the bottom plate and then shove in a section from a pool noodle? Like a central backer rod? And then keep going with a good bead of caulk between the bottom plate and the steel? Great stuff just doesn’t seem impermeable enough to me. I guess the key is to get in there with a bottle brush and sudsy water and scrub it real good and blast it clean with compressed air and let it be good and dry before I do whatever it is I do. I’m going to want to be sure there’s no rat latrine residue on that concrete so that cleaning step will be pretty extensive anyway.

After I seal up the edges should I try rockwool insulation. What do you think of that against galvanized steel? Since I only have 2×4 studs on 2’ centers can I use that stuff they sell for soundproofing interior walls? I thought it used to be stocked at the big box stores but now i don’t see it. What happened? I have to figure out what I can get in small quantities. Remember I’m in zone 2. Hot humid. Barely gets below freezing. The slab bridging between conditioned and unconditioned space is not a big deal. I just want to keep animals and water vapor out. I’ve got a lot of Corian countertops for workbenches with thermal mass. I’m planning to use Hardibacker for the interior side of the exterior walls for more thermal mass. Also, for the low cost and because it fits in my car.

I usually use icynene spray foam but I would like this shed job to be reversible. I can imagine somebody might want to disassemble the whole thing one day to reuse the materials in a more aesthetic building. But a sprayed application would conform to the shape of the steel. And I could have them do the underside of the metal ceiling/roof at the same time. Then I wouldn’t have to figure out how to get insulation to stay up there when I only have purlins on 4’ centers. I guess the sheets of foam that are 4’x8’ would work. That won’t fit in my car though. If I’ve got to pay for delivery I might as well get spray foam. It’s a tough call! Guess I have to run the numbers and choose the cheaper way.

Is Rockwool stiff enough to stay up by itself while I get some kind of ceiling over it? I might splurge on tongue and groove pine on the ceiling so I can hang lights and camera mounts wherever I want. The ceiling will be the only part that can’t get covered up with projects so it can be the prettiest. I guess I can put up a few ceiling boards and then shove in batts of insulation as I go along?

Now about plate glass walls. I don’t have the door tracks anymore. I sold them for scrap years ago. (There’s good money in extruded aluminum.) I can take the aluminum frames off the glass and just have double pane tempered panels. I have 8 doors, 4 each of 4’ and 3’ widths. I figured there would be some kind of wood or PVC profile I could buy that is made for this. They do it in offices all the time. I can usually find this stuff online but this has me stumped. Plate glass window on the floor. How?!

I have done it before, and my solution was wacky. I left the aluminum frame on the glass and just plonked it right down on a piece of Hardiplank caulked to the floor. Then I caulked on some brick mold for a stop. There has GOT to be a better way. Thanks for weighing in on. I’m not going to start this until it cools off so I really am going to wait to see if you all have any good ideas.

Related Links:

- How to Insulate Walls With No Sheathing

- Building a Shed? Get the Site, Footings, and Floor Frame Right

- Insulating Glass Keeps Getting Better

END NOTES:

Check out the Members-0nly Aftershow Podcast.

Check out one of our Project Guides: Siding & Exterior Trim!

Check out our FHB Houses:

Visit the Taunton Store • Magazine Index • Online Archive • Our First Issues • All Access

Help us make better episodes and enter for a chance to win an FHB Podcast T-shirt: www.finehomebuilding.com/podcastsurvey

If you have any questions you would like us to dig into for a future show, shoot an email our way: fhbpodcast@taunton.com.

If we use your question we’ll send you a FHB Podcast sticker!

FHB Podcast T-shirts!

Represent your favorite podcast! Available in several styles and colors. Made from 100% cotton. Find the Podcast t-shirt and more cool products in the Fine Homebuilding Store.

This episode of the Fine Homebuilding podcast is brought to you by Andersen Windows.

Fine Homebuilding podcast listeners can now get 20% off anything in the Taunton store, including Pretty Good House.

Use the discount code FHBPODCAST to take advantage of this special offer.

We hope you will take advantage of a great offer for our podcast listeners: A special 20% off the discounted rate to subscribe to the Fine Homebuilding print magazine. That link goes to finehomebuilding.com/podoffer.

The show is driven by our listeners, so please subscribe and rate us on iTunes or Google Play, and if you have any questions you would like us to dig into for a future show, shoot an email our way: fhbpodcast@taunton.com. Also, be sure to follow Fine Homebuilding on Instagram, and “like” us on Facebook. Note that you can watch the show above, or on YouTube at the Fine Homebuilding YouTube Channel.

The Fine Homebuilding Podcast embodies Fine Homebuilding magazine’s commitment to the preservation of craftsmanship and the advancement of home performance in residential construction. The show is an informal but vigorous conversation about the techniques and principles that allow listeners to master their design and building challenges.

Other related links

-

- All FHB podcast show notes: FineHomebuilding.com/podcast.

- #KeepCraftAlive T-shirts and hats support scholarships for building trades students. So order some gear at KeepCraftAlive.org.

- The direct link to the online store is here.