The Many Benefits of Design-Build

For high-performance builders, this collaborative model is hard to beat.

Synopsis: Josh Salinger of Birdsmouth Design Build describes the drawbacks of the design-bid-build sequence when builders work on projects designed by a separate entity, and goes through the pros and cons of the design-build model. Core to design-build is the iterative design process, which allows the team to learn faster on each project and improves performance and buildability.

When I started my construction firm, we acted as a general contractor, with building designs drawn up by third-party architects. Roughly eight years ago we switched gears, creating our own design team and going all in on the design-build (DB) delivery method. As a high-performance builder, we’ve realized that changing our company from Birdsmouth Construction to Birdsmouth Design-Build was one of the smartest moves we’ve made.

While the traditional design-bid-build (DBB) method has its place, we’d grown tired of its inherent inefficiencies and frustrations. These are especially significant for builders like us, attempting to build zero-energy homes that are healthier, more comfortable, and more resilient than the industry standard, and at the lowest possible premium. By bringing the design and construction teams under the same umbrella and keeping them in contact through every stage, not only are we building better homes at a lower relative cost, but we’ve also been able to innovate at a faster pace and improve our relationships with clients.

At the heart of the DB system is the iterative design process (IDP), which allows time for our team of designers and builders—with input from third-party experts such as structural engineers and landscape architects—to generate, test, and tweak ideas, and then to repeat the cycle until solutions are optimized. The DBB process, in comparison, tends to be forward-only, leaving builders to be more reactive than proactive, forced to do their best with plans they had no part in conceiving.

Problems with design-bid-build

In the status-quo delivery system for custom homes, the client starts by hiring a designer/architect. Sometimes they reach out directly; at other times they reach out to a builder first, who refers them to an architect. The client describes their program (vision and goals) to the architect, who asks about where the building is to be built, what the client’s budget is, what their wants and needs are, and how long their timeline is, before gathering info about the site and any jurisdictional limitations or rules.

While creating the design, the architect typically sends the plans to a structural engineer to size posts, beams, footings, and other structural elements, and engages with landscape architects, interior designers, and other specialty consultants to flesh out the details. At some point the design is submitted to the local building department for permit. In the meantime, the architect refines the construction drawings with connections, assemblies, schedules, and finishes. After all is said and done, there’s a lot of inertia behind the design, and a lot of money is spent.

When the design is completed and approved, the project goes to bid, with the client requesting construction proposals from up to three or more contractors. One big reason our team moved away from the DBB model was to avoid the race to the bottom. The intent of the bidding process is to create competition and keep costs from ballooning. However, since builders usually aren’t paid for this professional service, they have limited time to create an accurate bid or offer their expertise on constructability, materials, methods, or a host of other critical factors. At the same time, their incentive is to keep the numbers as low as possible. This tends to make bids inaccurate and poorly informed.

Often the client is inclined to go with the lowest-priced builder and hope for the best. The reality check is inevitable, of course, and soon the builder and client are at odds. At other times the bids come back as much as twice as high as the architect had expected. In this case, the project either gets abandoned or whittled down. This whittling usually affects the quality of materials or assemblies, not the overall scope of work or size of the home, which ultimately lowers the quality of construction.

A big problem with DBB is the limited interaction between the architect and the builder. In many cases, the architect hands off a set of plans to the GC, and neither hears from the other again. Clients can pay for quality control and construction administration as a part of the design contract, which often adds an additional 10% to 15% to the architect’s fee. It keeps the architect in contact with the build team, but most buyers don’t opt for this service, being focused on initial costs and failing to understand the return on this investment.

That leaves the builder to make tough decisions and navigate competing goals. The results are costly: frustrating changes and delays, cost overruns on materials and subcontractors, lower quality work, and difficult communications that erode trust. Making matters worse, there is often too much or too little information in the plans. Too much allows less room for flexibility; too little forces the builder either to make assumptions or to slow things down with endless meetings. In the end, no matter how well-intentioned the various stakeholders are, expectations and outcomes are likely to be misaligned.

The DBB process is simply not structured to optimize outcomes in budget, timeline, quality, or relationships. Being handed a set of plans that were crafted by a third party, with engineering included and a client’s heart already set on floor plans and features, makes it next-to-impossible to shoehorn in comfort, air quality, resiliency, durability, and lower-energy goals in a cost-effective way.

Worse, the attempt to improve performance at this late stage tends to result in high-performance building being pigeonholed as expensive and time-consuming—when it would have required only a small premium (and realized a very high return) if it had been considered from the outset. Even when a third-party architect is skilled at high-performance design, their solutions may not be cost-effective for a given build team. One example is forcing a builder to use double-stud walls when their usual path to the same energy goal is continuous exterior insulation. Another is when a builder has access to a more cost-effective material or supplier than the one specified.

How design-build is different

The DB model is actually the more traditional one. Architects working at the turn of the last century had to be master builders also, responsible for all aspects of a project from design to construction. As the Industrial Revolution got underway, however, specialization and high production over high quality became the trends—and the design and construction professions split apart.

Our goal in returning to the earlier model was to strive for higher quality by reuniting these two entities, without losing the advantages of specialization. Instead of focusing all the expertise and decision-making into one master builder’s brain, a design-build firm gives it to several specialists, but it places them all on one unified team that speaks with one voice.

At our DB firm and many others, design and build are in-house, while structural engineers, landscape architects, and other key consultants are brought into the discussion at critical points. While the major stages of design and construction are the same in DBB and DB—from programming to schematic design, design development, construction documents, and construction administration—DB’s integrated approach changes everything. Build team consults on design. At Birdsmouth, we have a licensed architect and an architectural designer (who doubles as our energy modeler) on staff, as well as a full build team, which includes project managers in the office, site managers, lead carpenters, and so on.

Shortly after a design contract is signed, during the earliest phase of schematic design, the site manager is brought in to consult on the floor plan and massing (shape, volume, and location of the building), as well as the proposed structure, assemblies, and systems involved. This high-level discussion might include deciding on trusses versus hand-cut rafters and the labor implications involved, or material availability, or site-access issues that may not have occurred to the design team. It’s much easier and less costly at this point to make changes such as reducing square footage or simplifying the design than when the structural-engineering and permit sets are already completed, as they would be in the DBB process. A landscape architect might weigh in at this point, with an invaluable perspective on views, drainage, driveways, or retaining walls, for example.

The construction team makes another scheduled appearance when the schematic design is fleshed out. The site managers and lead carpenters give feedback on constructability, and the project manager adds line items to the working budget with realistic cost numbers for each. As the project moves to design development, the structural engineer is brought in to provide instructions for specific assemblies or preferred structural components based on the team’s guidance. The project manager then gives feedback on the costs of those components, and the build team might offer suggestions to the engineer on how to make things easier to construct, simplify an air barrier, reduce thermal bridging, and so forth.

The results are critiqued once more by the lead carpenter and site manager, and eventually the design is presented to the entire build team so that even the apprentice carpenters can add input and get to know the project. This design process leverages the acquired knowledge of the build team, as well as key consultants—all of whom are smart and creative people—and all ideas are welcome. In one case, a client’s nine-year-old child came up with a way to borrow space from a bedroom to increase storage in the kitchen.

Budgeting is early and accurate. At Birdsmouth, we turn the DBB pricing process on its head. Instead of starting with the design and then attaching pricing to it, we start with a budget target and design to hit it. The team has current, direct experience with construction costs and can help define a realistic budget for the client’s scope of work. To do that, we often refer to recent projects, sites, and assemblies, drawing on our real-world construction experience and current market pricing.

If the budget is higher or lower than expected during the initial cost study, the client can choose to adjust the schematic design or have the teams return to the table to add, subtract, or substitute elements or square footage until the basic design and budget are in alignment. Obviously, it’s easier and more cost-effective to make changes at this point, when the design is basically a sketch on paper. This initial cost study lets clients know exactly what they’ll be getting, and the budget has the best chance of staying on target. In our experience with DBB, we found that even the best-informed architect will have trouble estimating true costs, usually ending up on the low side. Once the schematic design is complete, the team moves on to design development, crafting detailed plans with continued input from the build side, with the budget target always paramount.

Construction goes faster. When construction begins, the build team knows the design inside and out—because they helped create it. They feel a sense of ownership and stewardship, and they know why certain design decisions were made. Issues and second-guessing that may have otherwise arisen during the build have already been hashed out, heading off expensive delays and changes. In short, the build team is ready to roll and has very few questions.

When the inevitable hiccups do happen, everyone is on the same team, sorting through the issues with the original goals in mind and responding to the client quickly and clearly.

Quality goes up. For us, quality was the main driver for change. With the DBB method, by the time a set of plans arrived on our desk, with a client’s heart already set on the details, it was too late to make the substantial changes needed to reach the client’s zero-energy goal. For example, we often found it difficult to create a continuous air barrier or continuous thermal boundary. Stuck with major decisions such as inefficient massing, poorly placed or sized windows, or major thermal bridges, we couldn’t sufficiently lower heating and cooling loads to meet zero-energy goals. Also, some assemblies were unnecessarily complex or expensive, while others were underdesigned, often with no room or planning for optimal mechanical systems.

Sure, some changes could be made, but how extensive, and at what cost? When we suggested alterations or substitutions, we often felt like we were picking apart someone’s dreams, criticizing the architect, and blowing the budget in pursuit of “green building.”

Another critical difference is that DB is a simple partnership between the design-build firm and the client, who are both focused on a common goal. Expectations are easier to sort out and manage, and communication is faster and more effective, minimizing the potential for animosity. There is no waiting for the architect to write to the engineer for clarification, the engineer to respond, the architect to reply to the builder, and then the builder to relay all of this to the client, along with cost implications.

The DB team is both architect and builder, and they can simply reach out to the engineer and client to work things out quickly. The usual game of telephone goes away. Since there is just one entity to deal with, the client is less likely to end up in the middle of a finger-pointing situation, not sure who to believe. My DB firm isn’t going to sue itself for design omissions or construction defects. We just work through them and make them right.

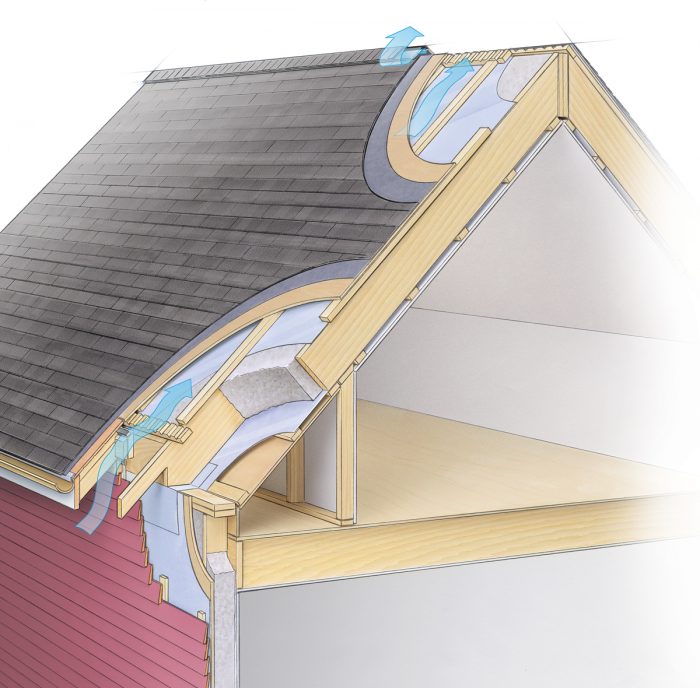

Design–build fosters innovationNone of the innovations from our firm would have been as likely to happen or as easy to refine without integrated design and build teams and the institutional knowledge they gathered over time. Zero energy for less Though the project was ultimately built by another firm, Birdsmouth poured all of its acquired knowledge into its recent Going Street Commons design (FHB #306), which delivered fully featured, zero-energy homes for a very small premium over code-built competitors in the same area. Key ingredients included condo-style land use, shared common spaces, simple house shapes, panelized construction, slab-on-grade floors, and floor plans that were repeated and flipped to bring costs down while controlling views and maintaining privacy. Foam–free vaulted roof In keeping with its mission to lower embodied carbon, Birdsmouth works to eliminate as much plastic-foam insulation as possible. This high-performance vaulted-roof assembly (FHB #299) packs R-44 of dense-pack cellulose between 2×12 rafters; durable venting channels below the sheathing prevent condensation and rot.  Concrete–free slab Concrete embodies a high amount of carbon, so Birdsmouth developed a unique approach to a plywood-based slab on grade (FHB #305), refining the gravel and insulation layers, the connections to vapor and air barriers, and the plywood sandwich itself. Recently, the firm began running the top layer of plywood at a diagonal to further vary the grain direction and create an even more solid feel underfoot. |

Challenges of the DB model

The design-build model certainly has its own challenges. First and foremost, it is a larger, more complex undertaking than running a separate design or construction firm. I know many architects who find their practices to be overwhelming at times, and they haven’t added an entire contracting business and all of its associated difficulties. The two entities require different certifications, licensure, insurances, recruiting, tools, and office spaces, among other things.

Conversion can be tricky. Having managed both types of firms in the past, I think that adding an architecture practice to an established construction business is the most straightforward path to DB. Construction companies are more complicated by comparison, with greater inherent risks and more moving parts. This is simply a reflection of my own experience and is not meant to diminish how complicated or risky an architecture firm is to establish and run. Others might choose to set up a DB from the get-go. Whatever path you choose, seek advice from business experts, architecture firms, construction firms, and experienced DB firms.

Greater client trust is required. With all the chips in one basket, it may require a greater leap of faith for a client to enter into a DB partnership. For example, with the build contract in hand, what is to stop the DB firm from charging whatever they want for construction? However, once the client sees how the DB team is working toward a common goal, a deep and resilient trust builds quickly, reinforced by empathy, honest communication, consistency, mutual compromise, and the common cause.

To ease the initial apprehension, we offer a number of strategic check-ins and off-ramps early in the process, and separate contracts for schematic design and design development. At either of those points, the client is free to take the gathered info elsewhere or scrap the project altogether.

Sticker shock comes earlier. Sticker shock is inevitable for most buyers, but it tends to come earlier for clients of DB firms. I would rather get it over with before construction starts than for the client to realize too late that the low bid was ill-informed and inaccurate. In my experience, since the DB team knows what’s needed to build a project, as well as current pricing, their initial budget target tends to be more realistic. Despite my efforts to explain this, some clients choose to walk away after the initial budget discussions, which I have come to accept. I’d rather be up-front and honest about costs; then if we can bring the cost down or add value later on, thanks to the DB process, nobody will complain. In my experience, the DB approach tends to cost less in the end, especially considering the long-term quality and value of the home.

Design stage is slower. The DB model is front-loaded, which tends to lengthen the design timeline. There are simply more ideas being considered and more iterations. This can be frustrating for clients used to the traditional process. The DB team isn’t simply design “experts” telling you how it’s done; there are gray areas, discussions, and competing ideas. The result of the messiness, however, is nuanced and optimized. And every hour spent on design saves multiple hours in construction time, which tends to proceed relatively smoothly.

Iterative design is better designA powerful lever in the DB method is the iterative design process (IDP), in which a concept or design is improved by questioning and testing ideas, tweaking them, and repeating the cycle until the solution is optimized. We design to a target budget and then continuously integrate feedback and recalculate the costs until the goal is met. For example, a client may see that adding a half-bath will push the budget past the original target but then find that the value is worth it, or not. Either way, the IDP helps us align expectations and thoughtfully clarifies both budget and scope. Buildability and performance are better Another benefit of the IDP is constructability. An architect can draw anything on paper, but building it is a very different proposition. In an iterative, integrated DB process, the build team can offer solutions that meet the intent of the design while saving time and money. Performance is boosted as well. The build team may suggest replacing the proposed mechanical system with one they recently installed. Or they may suggest that better-performing windows and increased airtightness would reduce the size of the mechanical system altogether, while improving interior comfort. From choosing insulation to refining critical control layers, identifying materials with shorter lead times, and finding substitutes for carbon-intensive materials, the IDP offers us an unmatched way to balance and achieve the shared goals of our firm and our clients. Teams learn more, faster The IDP makes the design and build teams stronger with each successive project. You have the same team members in place, in frequent communication, with each team challenging the other to improve assemblies and processes. Because each team understands better how much information the other needs, plans become just as detailed as they need to be and no more. It’s a process of continual education and growth. |

Lessons for traditional builders and buyers

My intent here has not been to diminish the architectural profession. A skilled, experienced designer is a critical component of any successful project. However, the traditional DBB model can be adapted to capture many of the benefits of DB delivery. For a start, I recommend choosing an architect at the same time one chooses a builder. Ideally, the two parties will have worked together in the past. Bring both stakeholders to the table at the earliest stages of design and make it clear that all ideas are welcome. Also, be up-front about the budget, and talk about it openly and often. And as I mentioned earlier, I recommend that clients pay the construction-administration fee so that their architect can remain part of the team all the way through the build.

But when I consider all the options, I think the design-build delivery system, done properly, is better for everyone. Since we made the change eight years ago, we’ve had happier clients, a happier staff, and projects that have been much more successful. Most importantly for our mission, we’ve been able to make durable, comfortable, healthful, zero-energy homes available to more people than ever, which is the whole point.

Josh Salinger is the owner and operator of Birdsmouth Design-Build in Portland, Ore. Photos by Asa Christiana.

From Fine Homebuilding #312

RELATED STORIES

View Comments

No question, you seem to have set up your program optimally for db and covered all the bases,mbut you ignore the elephant in the room…what if the client wants a different design aesthetic? /?not all architects are alike, let alone competent creative.etc I tried desperately to go this route but felt I couldn’t fit my vision desires aesthetics into the limited ones presented of the dB; architect. And let’s be honest, the most creative, talented architects are going to be in an architects firm, not working for a builder.I would say to any client prospectively, if the designer has never designed a house that comes cLose to appealing to you look elsewhere and that as true for a db form as it is for an architect cultural firm. That said if you cna for a db firm that’s built a house that appeals to you aesthetically, you’d be crazy to go the traditional route for all the reason you suggest. And in balance I suspect half the time builder will not be be able to under bid the db firm, especially if the db firm has been discussing closely with the client the real hard financial trade offs with precision as the design evolves, architects are useless at this beyond major things (yeah pivot doors are Expensive.etc)

All good points but y pu don’t discuss elephant in the room what if client is looking for a look your single in house architect hasn’t done? All your reasons become moot . And likely is it a client paying for custom build will go with an architect whose only designed nice farmhouses or semi craftsman but wants modern, or less likely vice versa??