Tool Test: Cordless Tablesaws

Portability and on-board power make them appealing, but utility and real-world performance vary by brand.

Synopsis: Cordless tablesaws aren’t yet that common on job sites, but they can be light and superportable, and more convenient on-site when power isn’t readily available. In this tool test, contributing editor Matthew Millham puts four cord-free saws to the test, comparing details of each saw’s fence, controls for adjustments, rip capacity, bulk, and price and naming one of the saws Best Overall.

Before lithium-ion batteries became the go-to for powering cordless tools, I couldn’t have imagined there’d ever be such a thing as a cordless tablesaw. Now we live in a time with battery-powered pickup trucks, and running a little tablesaw on that same technology seems like no big deal. Nevertheless, cordless tablesaws aren’t yet that common on job sites. But if you don’t like wasting money and you value your time, a cordless tablesaw might deserve a place in your tool lineup.

Consider the lack of power on a typical new-home build; the expense of buying, maintaining, and fueling a portable generator; and the time it takes to make fuel runs, perform oil changes, and get the generator running on a cold day. Add those up, and the relatively high sticker price of a cordless tablesaw suddenly seems less shocking. When power isn’t available, it’s far less costly to run a small generator to charge batteries than one large enough to power a tablesaw. Get enough batteries to run the tool all day, and you can forgo a generator altogether. Some cordless tablesaws are also light and superportable, making them convenient for common tablesaw tasks that don’t require huge capacity, like ripping stock for furring, face frames, and extension jambs.

I’ve been using Milwaukee’s cordless saw for four years, and I spent a few months testing saws from DeWalt, Metabo HPT, and Ryobi. They all come with thin-kerf blades to reduce the strain on battery-powered motors and increase run time. The thinner blades require slightly slower feed rates—and slower cuts—to minimize blade deflection. None of these tools are gimmicks. Some are capable of handling all (or at least nearly all) tasks a similarly sized job-site corded saw can, without the tripping and electrical hazards of plugging in.

That said, these cord-free saws do have limitations. If you plan on running them all day, you’re going to need more than one battery, especially if your crew includes “tentative cutters” who turn on a saw and then spend a minute or two contemplating how to make the cut as the blade spins. That’s free entertainment with a corded saw but frustrating to watch with a cordless, especially if you don’t have a fresh battery on deck. Obviously, batteries are a cost you don’t have with corded tools.

And while fine for everyday tasks, no cordless model will replace a corded saw for, say, resawing 4x4s, which is something I had to do in the middle of the pandemic when lumber was hard to get. For testing, I brought these saws to job sites every day, where they were used by carpenters, apprentices, and helpers with various levels of tablesaw experience. Here are the things I liked, the things I didn’t, and a general idea of what it’s like working with these tools.

STABLE STANDOUT

Milwaukee 2736

Table size 22 1/2 in. by 17 1/2 in.

Weight 41.6 lb.

Blade diameter 8 1/4 in.

Rip capacity 12 3/16 in. left, 22 in. right

Maximum depth of cut 2 1/2 in. at 90°, 1 3/4 in. at 45°

Price $600 (tool only)

I got my Milwaukee cordless tablesaw in late 2018. I liked it immediately, and it’s become my go-to job-site tablesaw. It only gets subbed out for a corded saw if I have to resaw or cut fly-ash trim, or if I know that the tablesaw is going to be running nonstop all day (as it did when I had to re-dimension 1600 lin. ft. of siding). The one thing that bugged me about the Milwaukee early on turned out to be user error. The riving knife wasn’t perfectly aligned with the blade, and I apparently hadn’t read the part of the manual where it describes how to fix this. The screws for adjusting the riving knife alignment are somewhat hard to access—but it is doable, and the saw has been pretty flawless since.

Milwaukee’s fence is controlled with a rotating knob, and it locks onto geared rails in the front and back. The fence moves smoothly, locks securely, and was true right out of the box. The saw provides good cut quality with the stock blade, but you’ll want a finer blade for finish work. (The same is true for all of the models discussed here.) It’s compact, portable, and about as lightweight as it can be despite its sturdy metal frame. Dust collection is fine so long as you attach a vacuum or other dust collector.

The Milwaukee’s controls are the best of the four. A standout feature is the riving knife lock/release, which is mounted under the table’s edge and allows the riving knife to be inserted and removed without removing the throat plate or fully raising the blade. The Milwaukee is also capable of (albeit limited) resawing—and it can accommodate a 6-in. dado stack up to 3⁄4 in. thick.

SOLID CONTENDER

DeWalt DCS7485T1

Table size 19 in. by 19 in.

Weight 45 lb.

Blade diameter 8 1/4 in.

Rip capacity 12 1/2 in. left, 34 3/8 in. right

Maximum depth of cut 2 9/16 in. at 90°, 1 3/4 in. at 45°

Price $550 (tool only)

DeWalt’s cordless tablesaw was the first on the market when it debuted in 2016, and while it’s similar to the Milwaukee saw in a lot of ways, it has some frustrating quirks that I’d guess Milwaukee learned from before introducing its version. First is the blade-height adjustment. It takes 35 turns to raise DeWalt’s 8-1⁄4 in. blade all the way, compared to 14 turns for Milwaukee’s. Then there’s the stand latch, which Milwaukee has and DeWalt doesn’t. If you want to move the DeWalt setup, you have to take the saw off the stand, reposition the stand, and then put the saw back on it—that is, unless you bolt the saw to its scissor stand, which either wastes time if you do it every day or kills its portability if you don’t.

To add or remove the riving knife, you must remove the throat plate, raise the blade all the way up, stick your fingers down to unscrew a wheel, and then press the wheel to release the knife. It’s easy enough for smallish hands, but it takes considerably more time and effort to do this than with the Milwaukee. Also, the DeWalt saw shut down during routine cuts a number of times in the three months I had it on the job, presumably from overloading. The DeWalt also doesn’t allow for dadoes—the arbor is too short to even try.

Milwaukee doesn’t win on every point, though. The DeWalt has more room behind the blade, which provides better outfeed support when you don’t have a competent helper and makes the saw more stable when used without a stand. Even without a latch, the DeWalt is plenty stable on its stand. (With all but the smallest or lightest materials, the Milwaukee is prone to tipping unless it’s on its stand and latched.)

NOT SO PORTABLE

Metabo HPT C3610DRJQ4

Table size 28-3⁄4 in. by 22 in.

Weight 58 lb.

Blade diameter 10 in.

Rip capacity 22 in. left, 35 in. right

Maximum depth of cut 3-1⁄8 in. at 90° 2-1⁄4 in. at 45°

Price $600 (tool only)

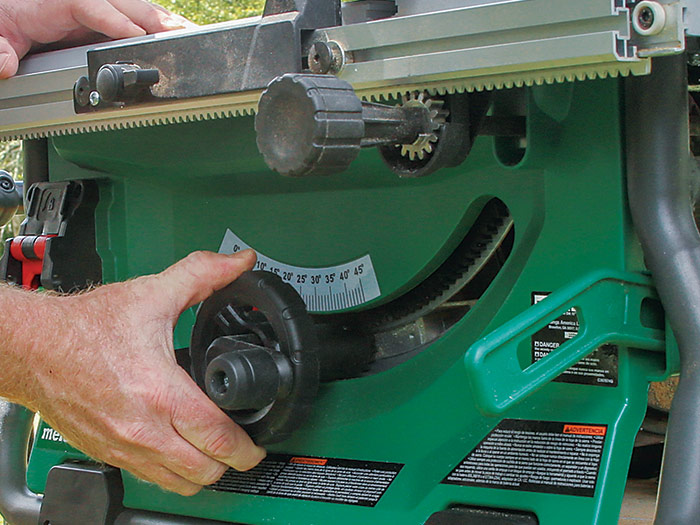

My hopes for this saw were high considering its 10-in. blade, 35-in. rip capacity, and extendable outfeed support, but my giddiness at its arrival wore off as I set it up. When I checked the fence for perpendicular to the tabletop (verticality), all was not well. Even with all the fence’s knobs and levers locked, the fence rotated out of plumb a few degrees under slight pressure. This might not be a huge issue for rip cuts, but it’s a major problem for resawing, which is one area where I expected this saw to outshine the others due to its larger blade. Because of its fence’s instability, I didn’t even try to resaw with it. On the other hand, it handled rips just fine and is one of only two saws here that can run a dado stack.

I’d be negligent if I didn’t mention that the Metabo HPT saw isn’t available as a kit with a stand. I couldn’t even buy a stand separately, as they were out of stock everywhere. With no other good options, I went with a DeWalt rolling stand that I modified slightly, but it was an imperfect workaround.

“Compact” and “lightweight” are two words that don’t belong anywhere near this saw. With a battery, the saw weighs in at over 60 lb. Add the stand (if you can find it), which has to be bolted on, and it’s even heavier. This bulk is not so fun if, like me, you have to heave it into a full-size pickup.

LIGHT BUT LIMITED

Ryobi PBLTS01B

Table size 17 in. by 12 1⁄2 in.

Weight 31 lb.

Blade diameter 8 1⁄4 in.

Rip capacity 7 in. left, 12 1⁄2 in. right

Maximum depth of cut 2 3⁄16 in. at 90°, 1 1⁄2 in. at 45°

Price $300 (tool only)

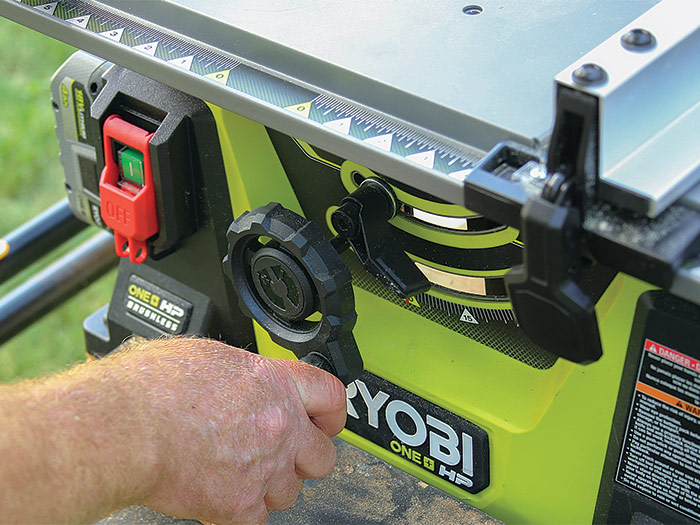

The Ryobi’s construction is what you’d expect from the least expensive and lightest saw here. It’s mostly plastic, and its metal table includes just one miter-gauge slot. (All the others have two.) It doesn’t have a carrying handle and can’t be stood on end. Unlike the other saws, whose fences mount on rails that can extend beyond the table, Ryobi’s fence engages the table directly, so capacity is limited.

The kit included two 4-Ah, 18v batteries and a charger. (I received the others as bare tools.) The saw needed significant adjusting out of the box. The blade wasn’t parallel to the miter slot, and the riving knife was out in every possible direction. Adjusting these was easy, thanks to a surprisingly good instruction manual.

Once it was all set up, the Ryobi cut just fine, and the fence somehow stayed parallel to the blade—though I did check it every time to make sure, since it basically relies on the act of engaging the lock to push it into parallel. I used it to rip some PT framing lumber, some 5/4 oak boards, and some smaller pieces of plywood. Cut quality was plenty good enough for rough work, and it could probably handle finish cuts with a blade finer than the 24-tooth one it came with. The lack of a compatible stand isn’t a deal breaker, but you’ll need a table or a piece of plywood and sawhorses to set it up on.

To view the entire article, please click the View PDF button below.

Contributing editor Matthew Millham is a carpenter for North River Design Build in Stone Ridge, N.Y. Photos by Patrick McCombe and Melinda Vazquez.

RELATED STORIES