Podcast 575: Costs of Custom Homes, Damp-Spray vs. Dense-Pack Cellulose, and Contractor Licensing

Improving the electric grid, tool batteries, making your own windows, value-engineering a new build, cellulose insulation, and contractor licensing.

Follow the Fine Homebuilding Podcast on your favorite app. Subscribe now and don’t miss an episode:

|

Help us make better episodes and enter for a chance to win an FHB Podcast T-shirt:

www.finehomebuilding.com/podcastsurvey

Richard has thoughts on power-tool batteries and the electric grid. David suggests making windows from teak. Lisa’s new house is too expensive. Doug asks for help deciding which type of cellulose insulation. Chris wonders about how to get a contractor’s license when he can’t prove he has two years’ experience.

Editor Updates:

- Ian’s winery-sized garden

- Mike’s large garden and tree dropping

- Jeff’s lawn mowing

- Patrick’s table project

|

|

|

|

Listener Feedback 1:

Richard writes: While there may be a real need to increase the electric-grid capacity in the next 10 to 20 years, it is not as hard as duplicating 100 years of past construction.

First, because Westinghouse won over Edison, distribution can add capacity by simply increasing the voltage on existing cables. Higher voltage at the same amps equals higher power—no wire size change needed. It does require changing transformers or their taps, which is relatively easy.

Second, existing right-of-way and towers can add additional lines. It’s more difficult, but it eliminates right-of-way concerns. Adding generation is the real challenge, especially when coal and nuclear is in the crosshairs of some. However, wind- and grid-tied solar is clean and already incentivized, as are energy-conservation measures. Some pie-in-the-sky electrification won’t happen as long as natural gas and affordable gasoline remain. Furnaces will remain for many, as will gas cars.

Related Links:

- The Power Plant of the Future

- Practical Ways to Electrify an Old House

- How it Works: Grid-Tied PV Systems

Listener Feedback 2:

Richard writes: The issue with battery adapters is the lack of standardization of the safety communication protocol between the tool and the lithium battery. The anything-goes strategy will have earlier consequences here.

While not a hot-button issue, I tend to agree with the recent comment concerning power tool battery standardization. Suggesting standardization would limit innovation seems unlikely since they all perform the same functions (e.g. provide voltage and ensure safety through a communication channel to the tool). The tool has the controller and the motor is where the innovation occurs, primarily using permanent magnet inverter-driven motors (marketed as “brushless”). Better battery chemistry and manufacturing techniques allow more amp hours, which provides more runtime and instantaneous

amp sourcing. But those battery improvements are independent of the connector and safety interface.

Maintaining proprietary batteries ensures non-standardization of the physical layout and tends to push a user to stay within a brand rather than shuffle multiple chargers and excess numbers of batteries to the work site. An argument could be made that the current situation could discourage a user from using a better tool from another manufacturer.

I believe power tool batteries could be standardized from a connector and safety perspective while still allowing increased performance to evolve, to say nothing about the impact increased competition would have on battery prices. It probably won’t happen until a lithium battery causes a significant fire because of a lack of standardization.

Related Links:

Question 1: My plans for my new house are too expensive. What can I do?

Lisa writes: Hello,

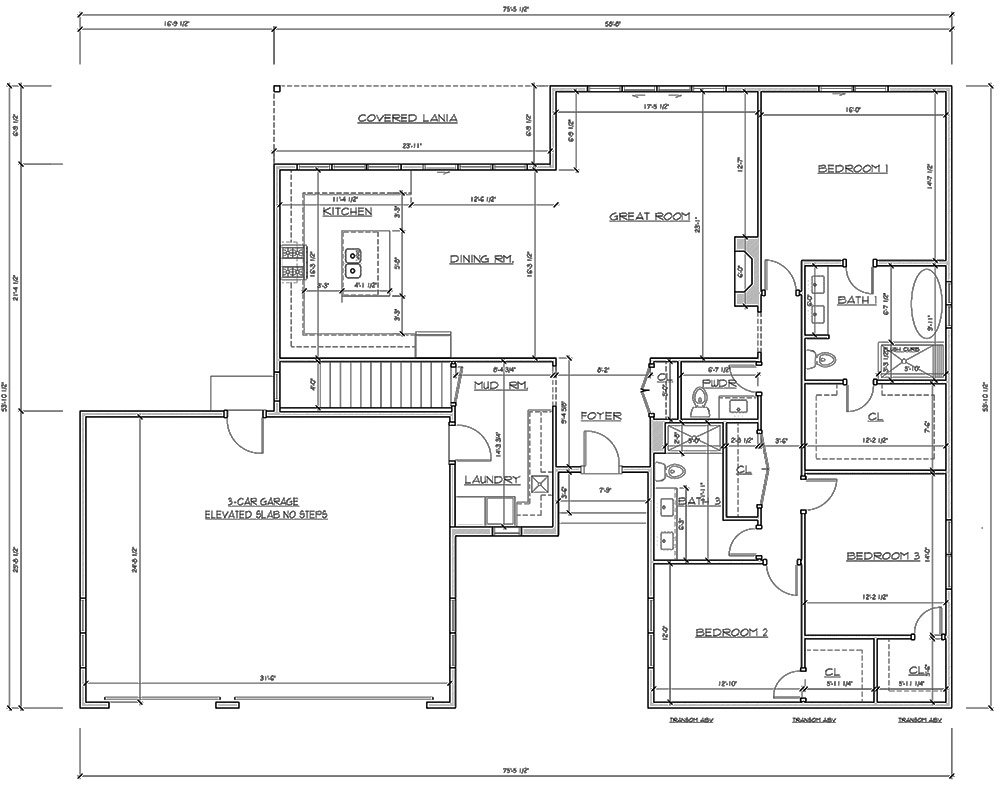

OMG! OMG! OMG!!!!! What would I do if I had not subscribed to FHB and stumbled upon the FHB podcast? (I started with JLC but needed more.) I am responsible for all aspects of my (our) “forever home” to be built. We bought 2.3 acres and plan for a 3-bedroom, 2.5-bath home. At 62, and a retired nurse, I am overwhelmed by the decisions I have to quickly make. I (we? – he still works and has no time) have so many questions. Having spent my sleeping hours listening to your podcast, I have yet to hear about steel siding pros and cons. Does it need to be insulated? Should I consider it? What’s appropriate for window choices for a new build (most of the companies are replacement)? Why does a 2300-sq.-ft. house cost $800K+ to build in 2023? Efficient green heating options appear to be out of the budget. What does the typical homeowner do to stay within the constraints of a moderate budget?

Homes in the East (New England area) seem to be way ahead of the Midwest in terms of having more affordable sustainable options. Homes go up fast. In what order would you spend your money for a new build?

We planned for a post-and-beam construction, midcentury-modern ranch with a basement. Now I’m told by the builder that I have to make alternative decisions because my steel beams, windows, and siding choices are too expensive. Heck, I take notes in my sleep and chose my options based on your podcast. Maybe I should sleep instead. HAHAHA!

Thanks for any suggestions.

Lisa

Related Links:

- Building the Best Affordable House: 10 Tips for Getting the Most House for Your Money

- Calculating the True Cost of Construction

- Affordable Net Zero

Question 2: What’s better: dense-pack or damp-spray cellulose?

Doug in Colorado writes: Hi Ian,

I just watched your ProTalk interview with Dan Kolbert. A lot of time was spent discussing dense-pack cellulose. I have heard it discussed on the regular podcast but never seen it done. What is the difference between that and wet-blown cellulose with a binder that is sprayed into stud cavities from the interior of the house? Do they both have the same performance?

Thanks,

Doug

From Ian:

Doug,

Thanks for listening and writing in.

My experience is limited to dense-pack cellulose, but I reached out to a few colleagues who have used wet-blown cellulose as well. The consensus was that the performance end result is the same, and that the deciding factor is what equipment the installer has. One benefit of the wet-blown method is that it does not require the netting that dense pack does, and the skill level needed to achieve a high R-value is lower with wet-blown equipment. One con to wet blown is that many high-performance builders would prefer not to add the moisture to the assembly.

Thanks again for writing in.

Ian

Related Links:

- Cellulose: The Perfect Insulation

- Insulating With Damp-Spray Cellulose

- How to Install Dense-Packed Cellulose Insulation in Walls

Question 3: How do I get a contractor’s license?

Chris from YouTube writes: How do I get my contractor’s license without actual proof of two years’ experience?

Related Links:

END NOTE:

From The New York Times — Testing New York Apartments: How Dirty Is That Gas Stove, Really?

“…a team of scientists from Stanford recently embarked on a testing tour of New York City apartments to better understand the extent of gas stove pollution and how it flows from room to room in people’s real homes. It’s part of a 10-city study that is already showing how contaminants can quickly drift into living rooms and bedrooms, sometimes far beyond the stoves that created them.

Concerns over the health and climate effects of gas-burning stoves have already prompted some cities and states to seek to phase out natural gas connections in new buildings, and the federal government has also moved to strengthen efficiency standards for gas stoves. But the issue has become a polarizing one. Last week in Washington, Republicans convened a hearing of the House Oversight Committee “examining the Biden administration’s regulatory assault on Americans’ gas stoves.”

The three-bedroom apartment they were visiting — home to Tina Johnson, a mother to three adult children — overlooks elevated train tracks and has an eat-in kitchen filled with the aromas of herbs and spices that she uses to make her favorite dish, an American-style ratatouille. Mrs. Johnson had just cooked a breakfast of fried eggs and potatoes.

“I’m glad you’re here,” she told the researchers. A new stove had just been installed in her unit, but she still “can’t stand the smell” of the gas from it, she said. She had volunteered to participate in the study through a local climate group, Mrs. Johnson said, because she and her children have asthma and other health problems; she was eager to know what their stove did to the air they breathed.

The machinery quickly detected the change: a rise in concentrations of nitrogen dioxide — which, among other negative health effects, can irritate the respiratory system, aggravate symptoms of respiratory diseases and contribute to asthma. Concentrations climbed to 500 parts per billion, five times the safety benchmark for one-hour exposures set by the Environmental Protection Agency. (Concentrations of benzene, a human carcinogen that is present in cigarette smoke and car emissions, also tripled.)

The next day, the team was back testing at another location, this time at an Airbnb apartment in Central Harlem. Their goal: recreate a “big family or dinner party scenario,” said Yannai Kashtan, a Ph.D. candidate in earth system science at Stanford and a member of the research team.

In the course of about 40 minutes, levels of nitrogen dioxide topped 200 parts per billion in the living room, 300 parts per billion in the bedroom and 400 parts per billion in the kitchen, or double, triple and quadruple thresholds set by the E.P.A. for one-hour exposures. Benzene concentrations also tripled after the stove was turned on.

This stove came with a hood. “But feel this,” Mr. Kashtan said, his hand in a stream of hot air that was blowing out from the hood’s edge instead of venting outdoors. That meant the hood “doesn’t make much difference” to the bad air, he said.”

END NOTE:

Podcast 575: Members-only Aftershow — Summer Projects

Mike, Ian and Patrick talk about their favorite summer projects, the ones the hate doing, and what’s best done in summer vs. other seasons.

Check out one of our latest Project Guides: Energy Retrofit!

Check out our FHB Houses:

Visit the Taunton Store • Magazine Index • Online Archive • Our First Issues • All Access

Help us make better episodes and enter for a chance to win an FHB Podcast T-shirt: www.finehomebuilding.com/podcastsurvey

If you have any questions you would like us to dig into for a future show, shoot an email our way: [email protected].

If we use your question we’ll send you a FHB Podcast sticker!

FHB Podcast T-shirts!

Represent your favorite podcast! Available in several styles and colors. Made from 100% cotton. Find the Podcast t-shirt and more cool products in the Fine Homebuilding Store.

| Fine Homebuilding podcast listeners can now get 20% off anything in the Taunton store, including Pretty Good House.

Use the discount code FHBPODCAST to take advantage of this special offer. |

|

“Finally, knowledgeable people talking about building reasonably-sized, high-performance houses for normal people with real budgets!” — DanD, VA, 8/19/22, Amazon.com review |

We hope you will take advantage of a great offer for our podcast listeners: A special 20% off the discounted rate to subscribe to the Fine Homebuilding print magazine. That link goes to finehomebuilding.com/podoffer.

The show is driven by our listeners, so please subscribe and rate us on iTunes or Google Play, and if you have any questions you would like us to dig into for a future show, shoot an email our way: [email protected]. Also, be sure to follow Fine Homebuilding on Instagram, and “like” us on Facebook. Note that you can watch the show above, or on YouTube at the Fine Homebuilding YouTube Channel.

The Fine Homebuilding Podcast embodies Fine Homebuilding magazine’s commitment to the preservation of craftsmanship and the advancement of home performance in residential construction. The show is an informal but vigorous conversation about the techniques and principles that allow listeners to master their design and building challenges.

Other related links

-

- All FHB podcast show notes: FineHomebuilding.com/podcast.

- #KeepCraftAlive T-shirts and hats support scholarships for building trades students. So order some gear at KeepCraftAlive.org.

- The direct link to the online store is here.