Close the Gap Between the Wall and Flush Built-Ins

Readers and an expert weigh in, considering options such as corner bead, caulking, and leaving a shadow line.

In a recent post, firsttimeroller writes that he has made several flush built-in cabinets. When installed, the cabinet face frames will be inset, flush to the adjacent walls. He’s also finished each of the wall openings with corner bead and joint compound. He asks “What’s the best way to close the gap and get a nice, clean look?” Up for consideration is stapling a plywood strip onto the face frame, recessed from the front to create a small space to be filled with joint compound, but firsttimeroller doesn’t know if the compound should actually touch the face frame.

That’s the topic of this Forum Spotlight.

The first response comes from agm413, who suggests using tear-away plastic drywall corner bead to fill the gap. This gets a thumbs-up from calvin. Firsttimeroller then asks if it makes sense to apply the tear-away bead over the existing corner bead, or if he should pull out the older corners and start from scratch. He has twelve cabinets, so that’s a lot of work to create a perfect finish.

Calvin comes back to say that he’s used both regular and tear-away corner bead in similar situations. “We would staple L-bead to the drywall, use Durabond for the first coat and it would hold fast. With mudded corner . . . might hold, might not. The staples have to go so they don’t interfere with subsequent coats. You’ve already built out the corner somewhat with your corner bead, but if you feather out the L-bead, it might appear flat.”

Calvin then offers an alternative: stuff the crack with foam backer rod that’s slightly bigger than the gap, ¼-in. into the gap. Mask each side of the gap with painter’s tape, then fill the gap with a flexible caulk. Use the putty knife to smooth the caulk, let it dry, and remove the tape. “I’ve caulked like this a lot. There’s a bit of a trick to it. Painters often do it. I’m just a dumb carpenter, retired.”

Firsttimeroller likes this idea. “I’m going to try this method. I’ve got the luxury of being able to cut the face frames to size (they aren’t glued on yet), so I can take my time and have a nice even space all around. I will try to attach the backer rod to the sides of the faces before I squeeze the cabinets back into the wall. If that doesn’t work, I’ll try the stuff method. Now you’ve got me wondering if I could even skip the caulk if I could find some other material to staple to the sides of the frames since they aren’t installed—vinyl compression jamb liners for windows maybe? Something that will fill the gap and look clean all in one.”

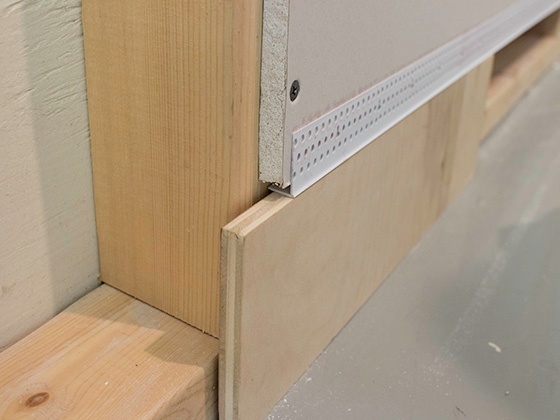

As the face frames aren’t installed yet, Calvin says he would remove the existing corner bead, pad out the opening with something appropriately sized, install the cabinets with the face frames attached, then use the tear-away corner bead to finish the openings. “The flush flat look is nice, but detailing that assumes the walls and cabs are in plane and everything goes as planned. You can ‘fool the eye’ but never fool yourself.” He then recommends instructional videos from Trim-Tex and includes a photo of a similar installation

The final two posts, from 1095mike and Alex2019, both recommend using a flexible caulk to fill the gap around the face-frame. They each cite that wood is prone to expanding and contracting with changes in humidity, and that if joint compound is applied next to the wood frames, the wood will absorb moisture from the compound and expand. When the compound and wood dry out, the wood will shrink, leaving a gap. A better solution is to use a caulk that will accommodate the movement of the wood.

An expert replies

FHB editorial adviser Mike Guertin responds with this:

I like the clean look when the drywall blends in almost seamlessly with trim elements. I’ve done this with flush installs of baseboard, door and window jambs, and cabinets. And I’ve tried numerous approaches that include terminating the drywall with regular metal corner bead, L-bead, tear-off-style beads, no bead, and fine caulk joints. They can all work, but some are more reliable than others in creating and maintaining the clean look.

One thing I haven’t tried is cutting cabinet face frames to match already installed drywall bead. It seems like a challenge, unless the corner bead is installed perfectly straight and without any variations in plane. Even if you could get a perfectly scribed face frame to fit the opening, it would be hard to adjust the frame in and out to account for slight drywall bead bulges outward or dips inward of the wall plane. And any deviation from perfect will be noticeable.

I recommend Calvin’s suggestion to remove the corner bead (or leave it in place), install the cabinets and face frames without scribing to the opening, and then install tear-off or L-bead. The bead can be adjusted tight to and flush with the perimeter of the cabinet frames. Then the joint compound can be blended to the wall plane to match the cabinet—an easier prospect than the other way around.

The caulking option is viable but does require that the gap between the face frames and corner bead be pretty close widthwise. There will be a difference in the wall surface finish, the face frame finish, and the caulk joint finish. The transition between materials will look fine if the gap doesn’t vary much, but if it does, the caulk line might highlight the gap variation.

I don’t recommend compounding right up to the face frames without a drywall bead as a stop, and don’t fill a gap between the existing corner bead and the face frame with joint compound. Inevitably the framing and/or the cabinet frame will move slightly with humidity changes in the house. The movement can cause the compound-to-face-frame bridge to fracture and chip out. Drywall bead isolates the cabinet frame so if there is any movement and a fine gap opens up, it still looks even, rather than jagged.

Another approach is to intentionally leave an even shadow-line gap between the corner bead and the face frame. I usually aim for a 1/8-in. to 3/16-in. gap. You still get a clean crisp look with some built-in forgiveness. When building elements move slightly and the gap width changes slightly, it doesn’t become unsightly as a tight joint would when it opens up. And if there are any slight differences in the plane of the corner bead and the face frame, it isn’t noticeable.

RELATED STORIES