Podcast 607: Wood Foundations for Winter Builds, Adding Headroom, and Aeroseal for Leaky Ducts

The crew hears from listeners about housewrap, replacing windows in brick openings, and managing heavy beams. Discussion questions include wood foundations, raising a ceiling in a ranch, and sealing up panned joist returns.

Follow the Fine Homebuilding Podcast on your favorite app. Subscribe now and don’t miss an episode:

|

Todd shares his method for new windows in brick walls. Barbara wants to know how Scott lifted his ridge beam. Larry wonders why there are so many different housewraps in a neighbor’s project. Kevin asks if you can use a PWF for a walk-out basement. Anna wants to remove her ceiling joists for more headroom. Marc is contemplating Aeroseal for joist-bay return ducts.

The Sustainable Home Building Accelerator

This intensive, interactive online series of courses is designed to rapidly advance your knowledge of sustainable home design and construction. Whether you’re an architect, builder, or a homeowner, we’ll give you the information and confidence to design and build well-crafted, practical homes that maximize performance and comfort.

Over 11 hours of video. AIA Approved 10 HSW/LU Credits. Resnet 10 PD Credits.

When you purchase all three courses, you’ll receive access to a year of GBA Prime as well as a copy of the Pretty Good House book!

Remember the code PODCAST20 for any Fine Homebuilding courses.

Editor Updates:

- Brian: home PV update, Larsen truss system

- Mike: taking care of rental properties — stuff people don’t know

- Jeff: fall clean up

- Patrick: Themed shows: Matt Omalia of Timber HP, Aeroseal to talk about duct sealing and Aerobarrier, framers plumbers, drywallers. And worst client, project, day on the job.

Listener Feedback 1:

Todd writes: FHB Podcast,

This is a response to the inquiry from Dan on the podcast on how to best handle flashing new windows in a house with brick cladding. I recently replaced all the windows in my own home that has a brick exterior. Thanks to Mike Sloggatt’s video series and article, I learned everything I know about handling this type of situation. But I think I might of figured out a better method. The first window I did, I followed Mike’s recipe and found myself frustrated with the process. The major change that I implemented was after reducing the size of the rough opening and adding window buck material to the same plane as the house exterior sheathing, I used trim coil as my first step in flashing the window. I cut 5-in. to 6-in. widths of trim coil approximately 10 in. longer than the width and height of the window area between the brick. I started in the normal flashing sequence with the bottom, then the sides, and capping off above the window opening. I used roofing nails only around the opening. I found it easier to tuck the trim coil in the air gap behind the the brick and integrate it with house’s WRB. I used bevel cedar siding to slope the sill pan, topped it off with Zip System Stretch Tape, followed with 3M tape on the sides and top of the opening. All of my tape wrapped around onto the trim coil covering the nail heads used to nail in the trim coil. This may not be helpful to Dan considering he doesn’t have any type of WRB, but I was really excited about how well this method worked. Love the podcast and please let me know what you think.

Related Links:

- Install a Full-Frame Replacement Window: How to Flash a Window Rough Opening in an Existing Brick Wall

- Install a Replacement Window in a Brick House

- How to Replace a Window: Flashing the New Window

Listener Feedback 2:

Barbara from Sactown (Sacramento), CA, writes: Hey Patrick,

I’m eagerly listening to episode 603‘s discussion of ways to lift a very heavy ridge beam. I hope Scott writes in with a follow-up email and tells us what he ended up doing. But I was thinking this topic would be a great FHB article. Hope you agree and can put it together.

Your friend and faithful audience member,

Barbara

Related Links:

Listener Feedback 3:

I’ve been watching this house in my neighborhood that’s undergoing a major renovation (note the addition on the back) and wondered how it came to be that three different housewraps were used. Did the contractor raid the leftover bin at his local supply house? Did he get a three-for-one deal on Ebay? I can’t remember ever seeing such a mishmash before in either new or remodeled construction. Is this even kosher? Thought you and the gang might get a chuckle seeing it.

I look forward every Friday morning to listening to the podcast on my 6:00 a.m. walk with my dog! It’s always informative as well as entertaining.

Related Links:

- Keeping Water Out of Walls: Housewrap and Beyond

- Nine Water-Resistive Barriers Worth Knowing About

- Peel-and-Stick Drainable Housewrap

Question 1: Can I install a PWF for my new walk-out basement?

Kevin writes: Hello all,

In a recent segment, Mike spoke about permanent wood foundations (PWFs) and the Southern Pine Council’s details. We recently began the excavation for our house, and I’m worried about the impact a concrete foundation might have on our build schedule due to the impending winter weather and contractor schedule. I’m interested in the feasibility of PWFs for our build, but I need a little clarification that I was not able to find in the IRC or Southern Pine Use Guide.

1) No detail included exterior insulation. I assume this is fine when installed on the outside of the poly membrane?

2) The IRC detail showed a maximum backfill of 48 in.; however, I couldn’t find the same spec in the Southern Pine Use Guide. We are planning a full, walk-out basement and 4 ft. of backfill on the high side won’t be enough.

3) Both the IRC and the Southern Pine Use Guide alluded to a maximum 8-ft. ceiling. Is there no way for a 9-ft. ceiling, with the last 2-ft. of the foundation exposed and not soil-bearing?

Thanks for all the help as always, Kevin

Related Links:

- Permanent Wood Foundation Design Specification (PWF)

- A Strong Case for Wood Foundations

- GBA.com: The BS* + Beer Show: Permanent Wood Foundations (PWFs)

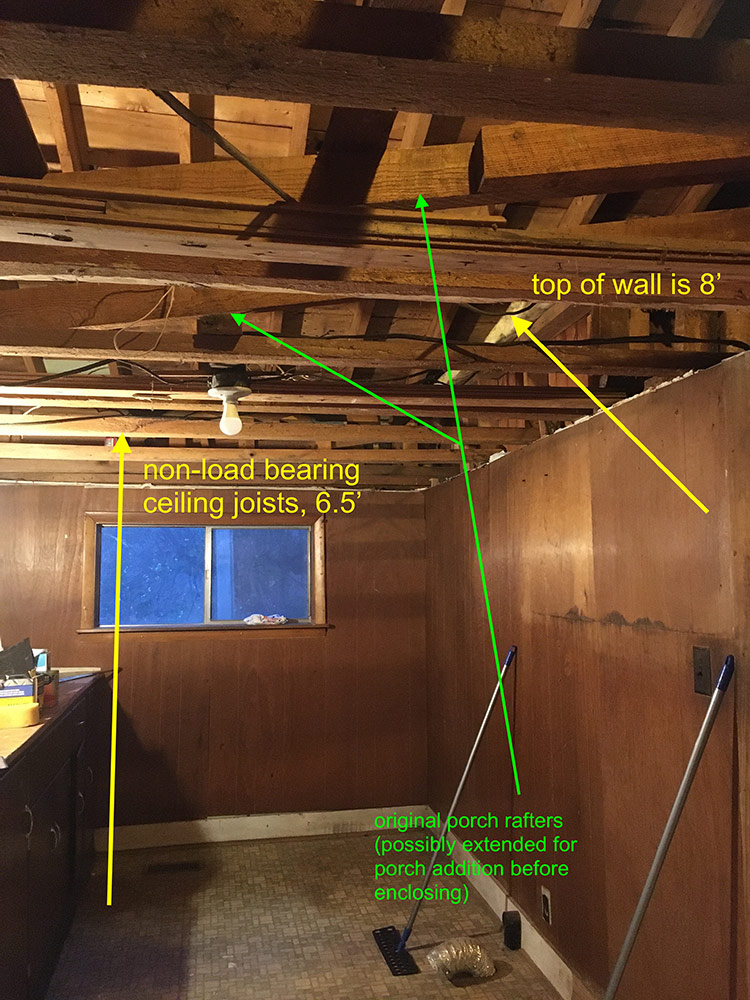

Question 2: Will rafter ties work for my ceiling, or do I need an LVL beam?

Anna writes: Hi FHB Podcast Team,

I have two questions: one about the podcast and a longer one about roof support in a DIY rehab project I’ve taken on.

Podcast question: I am an All-Access member and would like to download and listen to the members-only aftershow without having to watch a video on the website (not that y’all aren’t cute and all, but still…). I listen to podcasts while driving or doing physical work (I use the audio-only Overcast app), and I would like to listen to the aftershow in the same way (I can always go to the website later if for pictures or other visuals if needed). Is there a different app that will allow me to download the aftershow? If not, can you put it on the developer’s to-do list??

I’ve pulled down all the Hobbit-height Sheetrock (I’m 5’4″ and didn’t even need a stepstool). I can’t get any farther until I decide how to support the roof ridge so I can take out all the sloped rafters and put in a higher ceiling. Most everyone I ask, including my architect brother, says that rafter ties will be fine (there are collar ties up by the ridge), but the home inspector—a master framer in an earlier life—insisted that I really need an LVL beam for proper support.

|

|

Rafter ties I can probably manage myself (I’m an ambitious 61-year-old), but I’d definitely need help hoisting and securing a 20-ft. LVL beam—or more likely I’d just hire it out.

The current roof is metal (about 10 years old) on top of at least one layer of asphalt shingles. The decking is 1-in. boards and the roof and ceiling framing is pre-1974 rough-sawn timber that’s actual 2×4 or 2×6—good stuff I intend to save. Whether the eventual ceiling is vaulted or flat depends on the roof supports. If rafter ties, I envision using them as exposed ceiling joists. If a central beam, then the ceiling style is TBD. What do y’all think? Are many rafter ties going to be easier, less expensive, and/or as supportive as a single LVL beam? Can you even get 2x4s longer than 16 ft., and would it be safe to join shorter ties with metal plate connectors?

Thank you much!

Anna

Related Links:

Question 3: What’s the best way to seal existing ductwork?

Marc writes: Hi Podcast Team,

I continue to thoroughly enjoy the show and thank you for all the time and work that go into it.

I remember back in the day, the team said how undesirable it was to use the floor joists as part of the ductwork (fresh air returns, maybe…) in the HVAC system of a home. For homes that are already ducted that way, would AeroBarrier be a possible solution for leaving the ductwork ‘as built’ and rehabbing the problem?

Ross MacPherson, Application Engineer – Aeroseal Envelope (AeroBarrier) & Duct:

Great question. Aeroseal is a sister product to AeroBarrier, which is specifically designed for HVAC ductwork. Aeroseal would be the best product for this application. Every day, we seal systems with building cavities as part of the ductwork. For the best results, we recommend that the ductwork is cleaned prior to sealing. Typically, the duct cleaning and Aeroseal installation can be done in the same day.

The Aeroseal will not coat all the building cavity materials, but rather it will seal the gaps between these materials and significantly reduce the leakage from this distribution system. Reducing the leakage will lower the utility costs to operate the system and typically improves comfort in the home as the heated/cooled air gets to its intended destination as designed.

Marc again:

Now for the provocation: I receive a news blast from Builder Online, and the article linked below left me speechless. Pitching concrete as a more environmentally responsible building material than wood boggles my mind. I would love to hear the team’s thoughts about the article and the potential effects from broadcasting this type of misinformation in the industry.

Last time I checked, trees regenerate and grow new trees. I’ve never found any concrete seeds being shed by my foundation nor any concrete-lings putting forth their tender shoots on the way to becoming a bag of ready mix!

All the best,

Marc

Related Links:

- A Question of Sustainability: Wood vs. Concrete: What the science says might surprise you. — Brought to you by Build With Strength?

- How to Seal Leaky Air Ducts

- Air-Seal an Attic Series: Sealing Ductwork

END NOTE:

Podcast 607: Members-only Aftershow — Holiday Gifts for Home-Building Enthusiasts

Discussion about holiday gifts in several price ranges, including tools that can improve your work and make home building easier and more enjoyable.

This episode of The Fine Homebuilding Podcast is brought to you by Loctite’s Tite Foam

Say no to inefficient and drafty. Say yes to Loctite Tite Foam.

When pros need to seal gaps too small for insulation but big enough to create a draft, they reach for Loctite’s TITE FOAM.

The high-density foam forms a tenacious bond to most common building materials, stays flexible to prevent cracking, and keeps air, moisture, and pests out of the house.

Whether you’re adding R value to the rec room, or finishing a boring basement, give that space a second chance with Loctite Tite Foam.

Visit LoctiteProducts.com for more information.

Check out one of our latest Project Guides: Energy Retrofit!

Check out our FHB Houses:

Visit the Taunton Store • Magazine Index • Online Archive • Our First Issues • All Access

If you have any questions you would like us to dig into for a future show, shoot an email our way: [email protected].

If we use your question we’ll send you a FHB Podcast sticker!

FHB Podcast T-shirts!

Represent your favorite podcast! Available in several styles and colors. Made from 100% cotton. Find the Podcast t-shirt and more cool products in the Fine Homebuilding Store.

| Fine Homebuilding podcast listeners can now get 20% off anything in the Taunton store, including Pretty Good House.

Use the discount code FHBPODCAST to take advantage of this special offer. |

|

“Finally, knowledgeable people talking about building reasonably-sized, high-performance houses for normal people with real budgets!” — DanD, VA, 8/19/22, Amazon.com review |

We hope you will take advantage of a great offer for our podcast listeners: A special 20% off the discounted rate to subscribe to the Fine Homebuilding print magazine. That link goes to finehomebuilding.com/podoffer.

The show is driven by our listeners, so please subscribe and rate us on iTunes or Google Play, and if you have any questions you would like us to dig into for a future show, shoot an email our way: [email protected]. Also, be sure to follow Fine Homebuilding on Instagram, and “like” us on Facebook. Note that you can watch the show above, or on YouTube at the Fine Homebuilding YouTube Channel.

The Fine Homebuilding Podcast embodies Fine Homebuilding magazine’s commitment to the preservation of craftsmanship and the advancement of home performance in residential construction. The show is an informal but vigorous conversation about the techniques and principles that allow listeners to master their design and building challenges.

Other related links

-

- All FHB podcast show notes: FineHomebuilding.com/podcast.

- #KeepCraftAlive T-shirts and hats support scholarships for building trades students. So order some gear at KeepCraftAlive.org.

- The direct link to the online store is here.