Manage PVC Trim Expansion

Properly install PVC trim products during cold weather to prevent expansion, contraction, and bowing issues. Warm up the trim before installation for better results.

As a siding contractor working during a Minnesota winter, I had to be careful when installing products that have a high rate of expansion and contraction with changes in temperature. Trim products made of PVC are definitely in this category—if you install a PVC garage-door weatherstripping when it’s 1°F outside, when the weather warms up that weatherstripping will expand and likely bow out between the fasteners. Longer lengths and dark colors in the direct sun are particularly susceptible.

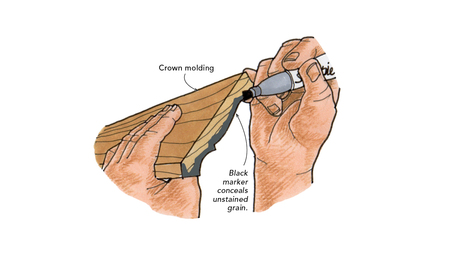

I’ve learned that whenever possible, avoid installing PVC trim if it’s very cold outside; but if you have no choice, warm up the trim before installing it. You don’t need to get it hot; room temperature will make a big difference—just bring it into a warm house and bring it up to room temperature. The trim will likely shrink a bit when it cools down and create small gaps at the joints, but those are much less visibly offensive and can often be concealed with elastic sealant.

—Mark Petersen, Waco, Ky.

Illustration by Charles Miller

View Comments

Excellent informational piece notating the high coefficient of thermal expansion endemic to cellular PVC trim and how best to account for it. Using such recommendations, I've found vinyl trim works well for casements for new construction vinyl windows installed in existing brick homes.

The article does well in stressing that such expansion and contraction tends to work against maintaining tight joints, key to professional-looking results. I would add to this the importance of using a caulk specifically engineered for high elasticity and adhesion. I believe synthetic rubber caulks are best for this application, one example being OSI's Quad Max. Although it's expensive and can be challenging to work with*, this caulk can be applied at ambient temperatures down to 0°F as well as in the rain. Most importantly, it will maintain joint adhesion throughout the significant cycles of thermal expansion and contraction inherent to PVC trim.

*Quad Max caulk requires significantly more force to dispense than typical caulks due to its high viscosity. Further, it cannot be tooled as this will ruin the UV resistance, meaning one has to pretty much 'get it right the first time.' Not only is it very thick, it is also quite tacky to the touch. This means things can go downhill quickly if one makes the mistake of sticking a finger in it or otherwise attempting to 'correct a mistake.'

The following tips could help in achieving the best results when using OSI Quad Max:

1. Make sure the product is as fresh as possible as it's basically a tube full of molecules anxious to bond with one another to form a solid. In other words, the tubes definitely have a finite shelf life after which the product becomes semi-solid. I recommend trying to buy product no older than six months; but the newer the better, so check the entire store shelf as this information is stamped on the side of each tube as YYDDD:

where, YY = Year of Manufacture; DDD = Number of days into the year

2. Prior to use, the caulk should be stored in a warm place for a few hours to lower the viscosity and make it easier to dispense.

3. With regard to application, a quality caulk gun should be used. Plan on squeezing hard and knowing that you are not going to lay down a glass-smooth bead of caulk. This is particularly the case when filling larger gaps (use backing rod for 3/8"+.) In those cases, if you're generating something that looks similar to a good weld bead, your doing just fine!