Sustainable and Stylish

The recipe for linoleum hasn't changed much in nearly 170 years, yet it's still one of the greenest floors money can buy.

Linoleum is an all-natural, antibacterial flooring product; it’s available in a wide range of colors, in sheets, tiles, and click-together planks. With health top of mind post-pandemic, and midcentury-modern design trends on the rise, it’s no wonder this flooring material is making a comeback.

One of the Greenest Floors Money Can Buy

Way back in 1855, an Englishman named Frederick Walton made a lucky discovery. He forgot to seal a jar of linseed oil that he was using as paint thinner and discovered that it formed a flexible, rubbery skin. Peeling it off, he began to wonder about potential uses. His thoughts went to flooring, where he knew there was room for improvement. Many houses at the time relied on homemade floor cloths, made from heavily oiled sheets of canvas, wool, or cotton, to add insulation to cold stone or wood-plank floors. These were thin and smelly, did not wear well, and tended to crack with use.

Walton’s experiments yielded a new material that he called “linoleum,” a portmanteau of the Latin words linum (which means flax) and oleum (oil). This material blended oxidized linseed oil with pine resin, cork dust, powdered limestone, and wood flour to create a granular mixture that was rolled out and pressed onto a canvas or felt backing. Used as flooring, it became enormously popular, quickly overtaking its competitors thanks to superior durability and water resistance.

Linoleum enjoyed predominance for many decades, until evolving technologies and tastes knocked it off its pedestal in the mid-20th century. The post-World War II era ushered in new synthetic polymers, such as polyvinyl chloride (PVC), which manufacturers discovered could be blended with asbestos and made into a solid, durable flooring that was cheaper, lower maintenance, and more vibrant-looking than linoleum. Vinyl took over (the asbestos was eventually removed), even appropriating its competitor’s name at times. This resulted in a generation of people not knowing the difference between the two, let alone understanding that real linoleum is, in fact, one of the greenest flooring materials that exists.

Fast forward half a century, and linoleum is making a comeback. It’s starting to reappear in green building guides, design magazines, and flooring supply stores. There are numerous reasons for this, from its stellar eco credentials and health benefits to a resurgence of interest in the midcentury aesthetic and its tremendous potential for creative design.

A Gold Star for Sustainability and Health

The amazing thing about linoleum is that, after all these years, its basic recipe has not changed much. It continues to be made from all-natural ingredients, which makes it a top pick at a time when more homeowners are concerned about the environmental and health implications of the products they buy.

The production process has been refined since Walton’s day. Forbo, a lead flooring manufacturer based in Switzerland, makes a branded product called Marmoleum that is available in North America. Its ingredient list consists of flaxseed oil, wood flour (timber industry leftover, no tropical wood), pine rosins (from controlled forestry locations), woven jute, limestone, and eco-friendly pigments.

The company describes production as an art form, stating on its website that you cannot learn how to make Marmoleum at any trade or craft school and that only a handful of people know how to do it. “Linoleum is such a unique product that there are only three manufacturers globally,” said Lori Lagana, marketing manager at Forbo, whose Marmoleum brand is the largest and most accessible to residential customers in North America.

The only other producers are Gerflor, with its DLW Linoleum collection, and Tarkett, with LinoFloor xf2. (An unconventional linoleum option, liquid linoleum, was created by Duracryl in the Netherlands and is sold by Mannington Commercial in the United States; currently liquid linoleum appears primarily in commercial spaces.) If you go shopping for linoleum, you are most likely to encounter Forbo’s Marmoleum—thus the brand name has become interchangeable with the product itself, frequently used to differentiate real or natural linoleum from its vinyl impersonators.

To quote Lloyd Alter, architect and frequent contributor to Green Building Advisor, “Linoleum is so natural, it’s almost edible. When we talk about building out of sunshine—using materials that we grow—this is top of the list for flooring.” Compared to other common types of flooring, linoleum has the lowest CO2e emissions based on 100 square meters (1076 sq. ft.). According to the Low Carbon Homes Pilot (LCHP) study, which analyzed 34 newly built homes in British Columbia, linoleum emits 36 kilograms of CO2e per square meter.

This is better than cork (68 kg of CO2e/m2) and vinyl (875 kg of CO2e/m2), and far better than hardwood (1440 kg of CO2e/m2) and laminate (2710 kg of CO2e/m2). In a 2022 report on building materials emissions, Builders for Climate Action recommended linoleum as a lower-carbon substitute for hardwood flooring, citing its wide availability and the fact that it meets all current code requirements and can be used in similar applications, including over heated floors.

Furthermore, linoleum is plastic-free. At a time when many homeowners are striving to reduce their plastic consumption, whether due to concerns about off-gassing or non-recyclability at end-of-life disposal, this is an appealing attribute. Alter also brought up the issue of microplastics that wear off every time you take a walk across a vinyl floor. Given the choice between two types of similarly performing floors, one of which is natural and the other synthetic, it is not surprising that increasing numbers of people are choosing the former.

Linoleum is attracting attention for its natural antibacterial properties, something that matters more than ever in a post-pandemic era. Independent testing conducted by the University of Glasgow found that linoleum (specifically Forbo’s Marmoleum) inhibits the growth of MRSA (an antibiotic-resistant bacteria that can cause infections) and other pathogens.

Tony Raj, owner of Danforth Carpet Connection in Toronto, said that more customers are asking for natural linoleum since the COVID-19 pandemic. “People are concerned about their health, asking which product is most natural.” Raj said some people with health issues are choosing to put linoleum throughout their entire house, seeking natural materials and better air quality.

Three Types of Linoleum Flooring

1.) Modular Tiles

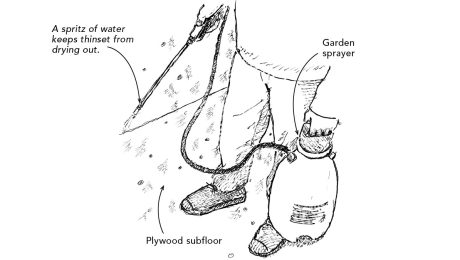

Linoleum planks or tiles, specifically the Marmoleum Modular tile available in the United States, can be installed over a range of substrates, most commonly concrete or wood. If working in an old house, you will need to remove the existing floor and prepare the substrate before adhering the tiles or planks, which require adhesive to install.

|

|

|

Slim and sturdy. Despite its thin profile (typically under 0.1 in.), linoleum is exceptionally durable and water-resistant, making it an ideal flooring for kitchens and bathrooms. Sizes: 2.5mm thick, available in four sizes: 10-in. by 10-in., 10-in. by 20-in.,10-in. by 40-in., and 20-in. by 20-in.

2.) Linoleum Sheets

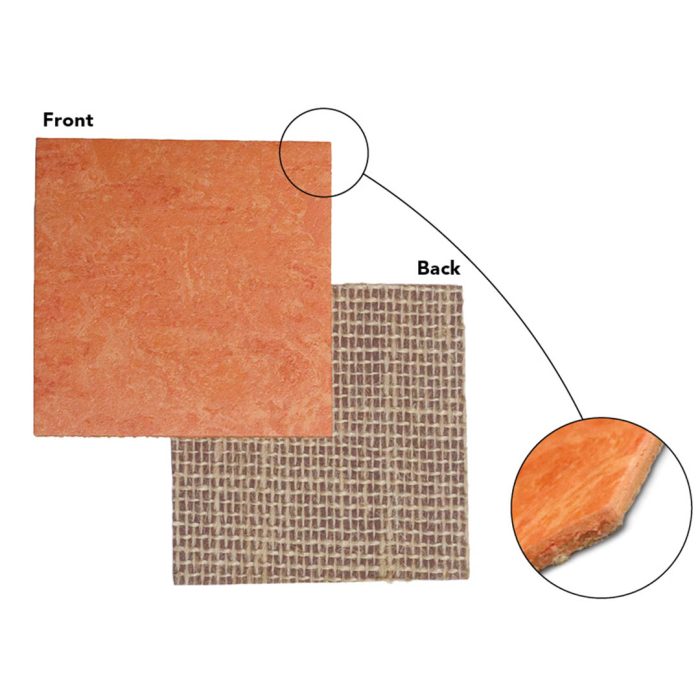

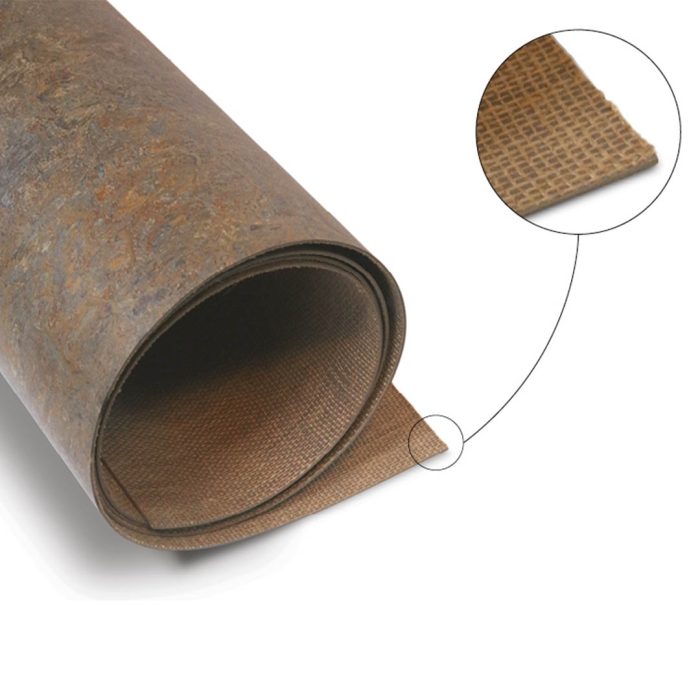

Linoleum sheets are available from three manufacturers in the United States—Forbo sells Marmoleum Sheet, Gerflor has its DLW line, and Tarkett produces LinoFloor xf2. Like tile, linoleum sheets require a prepared substrate and adhesive to install. Laying the sheets is precise, and handling the seams requires special tools and skills.

|

|

No plastic here. Linoleum is made of all-natural ingredients and backed with a woven jute (plant-based) fabric. Sizes: 2.5mm thick (2mm for certain styles), approx. 79 in. wide and available in rolls up to 100 ft. long.

3.) Interlocking Planks

The only linoleum click-together product currently available in the United States is Marmoleum Cinch Loc Seal, which—unlike sheets and tile—has a layer of Marmoleum on top of fiberboard and cork. It is the only product that does not require adhesive; boards slot together using a tongue-and-groove locking system, making them simple to install. Cinch Loc Seal is more forgiving and can tolerate slight unevenness—up to 3⁄16 in. over an 8-ft. span. This makes it suitable for old houses and renovations. The product comes in two sizes, as a plank or square, and is cheaper than Marmoleum sheets or tile, partly because it requires less preparation, no glue, and can go over many existing floors.

|

|

A three-ply sandwich. Cinch Loc Seal planks consist of a 2.5mm layer of Marmoleum on top, with high-density fiberboard in the middle and a cork base that acts as underlayment. Sizes: 3⁄8 in. thick. Available as 12-in. by 36-in. planks and 12-in. by 12-in. squares.

Broad Design Appeal

Trends never fail to come back around, and the midcentury-modern look of the 1950s and ’60s, right before linoleum lost its primacy to vinyl, is no exception. Architects, designers, and homeowners are embracing minimalist wooden furniture, mixed materials, houseplants, window treatments, and accent colors against neutral tones. Linoleum plays a big part in that—its warm, smooth surface conjures memories of grandparents’ and great-grandparents’ homes, providing a backdrop to vintage or retro-inspired furniture.

Advances in coloring mean that modern linoleum can become almost anything, from bold, bright, and blocky to marbled, patterned, and laser engraved. It can look like slate or concrete, have a granular consistency with the addition of cocoa shells, or appear shimmery with added color. The color permeates the material, so scratches are less visible. Its tremendous versatility makes linoleum the darling of some interior designers.

It’s even being used for purposes other than flooring, including as surface material for kitchen cabinets, counters, desks, and bar tops. It’s a great surface for writing on and easy to clean. Joel Hirshberg, owner of Green Building Supply, said that Marmoleum has been his company’s most popular flooring for many years: “It’s very versatile, with so many places to use it. It’s an inexpensive product that’s easy to install, looks great, and is eco-friendly. So, why not? It checks all the boxes.”

What’s the Cost?

In North America, linoleum is most easily purchased from Forbo, which produces three main Marmoleum products—sheets, tiles, and Cinch Loc Seal, a click-together flooring. Both sheets and tiles must be glued down with adhesive, while Cinch Loc Seal can float over existing floors. Most subfloors are concrete or wood (plywood or OSB), although Marmoleum can be installed over a range of substrates including poured (epoxy, polymeric, seamless) floors, strip wood or plank flooring, wood substrates, and other resilient existing flooring.

At Green Building Supply, all Marmoleum products are within the same initial price range of $3.50 to $6.50 per sq. ft. This is comparable to hardwood or wool carpet, is generally less expensive than bamboo or cork, and potentially could be twice the cost of vinyl. It is necessary, however, to factor in the costs of preparing the floor, installation, maintenance, and eventual replacement.

Hirshberg wrote, “Although the initial cost can be higher than vinyl flooring, for example, Marmoleum lasts almost three times as long. In addition, the regular maintenance of Marmoleum is generally much less expensive than vinyl.” And as Hirshberg explained, Marmoleum “has a full-body color, which means you can buff it out many times over the course of 30 or 40 years, refinishing the floor as needed.” But in most residential applications, you likely won’t need to do this for at least 10 years.

Alter says that while linoleum tends to be twice as expensive as vinyl, it’s “worth it.” Plus, a phone conversation with Hirshberg in August 2023 revealed that vinyl prices have been climbing lately due to sourcing challenges and tariffs in China. He said that vinyl manufacturers are actually having a hard time getting the product.

And even when available, there is a huge range in quality. The higher-end vinyl is comparable to Marmoleum in price, whereas the “cheap, buck-a-piece vinyl” that can be found at some home-supply stores is a much lower-grade product. Keep in mind that Marmoleum is 100% biodegradable. For homeowners who weigh the environmental cost of end-of-life disposal, this counts for a lot.

When quizzed about how he sees the future of linoleum, Hirshberg said, “I think it will become more common. People usually buy it again and again; they really like it, and that’s a great sign. They use it in one house and, when they move, they put it in another house. We have almost zero warranty claims for the product; it just holds up. It’s very durable and it looks really cool. There really isn’t anything like it, color-wise, and that’s one of the main reasons why people buy it, apart from health and climate. This stuff is beautiful.”

Frederick Walton would likely be thrilled to know that his innovative flooring material is still going strong, a century and a half later. That is the sign of a well-designed product—that it can stand up to wear and tear and fickle trends, while improving quality of life without causing undue ecological harm. So, the next time you’re floor shopping, give linoleum some serious consideration.

— Katherine Martinko; journalist, author, and expert in sustainable, low-impact living. Room photos courtesy of Marmoleum. Product photos by Rodney Diaz.

From Fine Homebuilding #323

RELATED STORIES