How to Add a Laundry Chute to Your Home

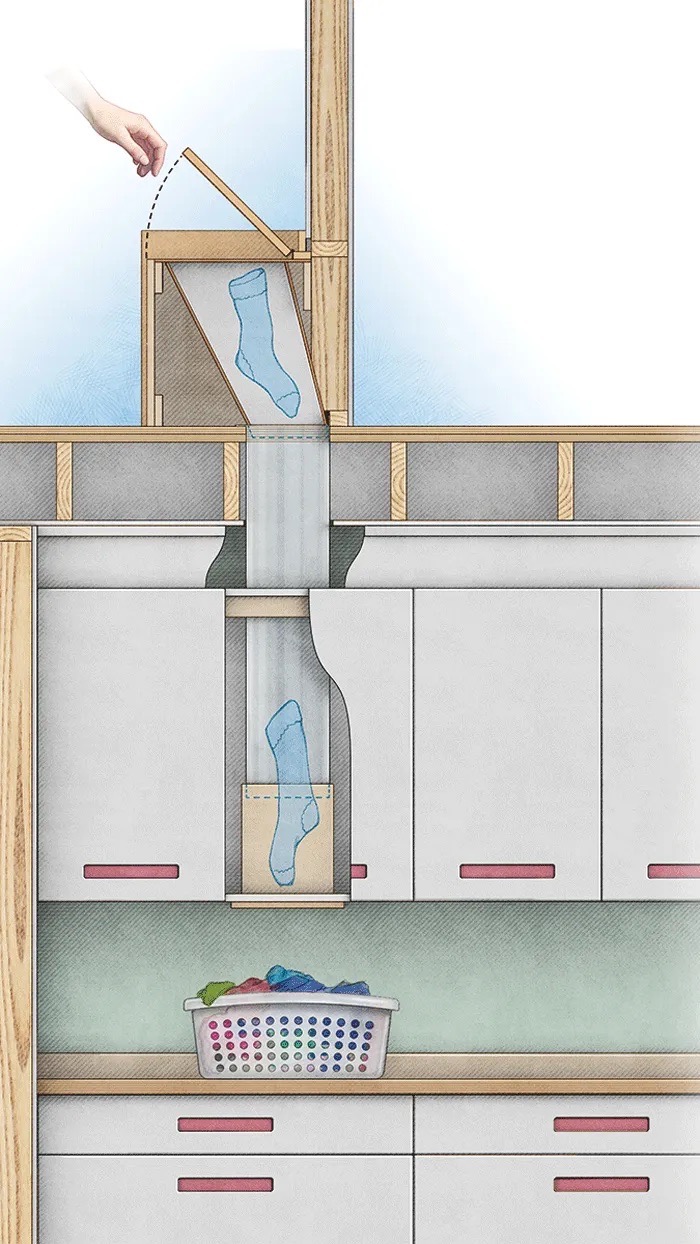

Learn how to plan, fabricate, and install a chute to conveniently send your dirty clothes from an upstairs bathroom or hallway to your laundry room below.

Project manager Steve Pink and woodworker Asa Christiana show the steps to building a basic laundry chute, from locating the chute on each floor, to cutting the inlet and installing the metal chute, to building the upstairs and downstairs cabinets.

Make Your Laundry Process More Efficient

In modern homes with automated lighting, smart appliances, and any number of other high-tech features, having to carry a laundry basket down two flights of stairs to the laundry room is an obvious disconnect. As a project manager for a large design/build firm in Portland, Ore., I’ve installed dozens of laundry chutes into homes both old and new. The chute shown in this article is a collaboration between myself and Asa Christiana, who is a contributing editor for FHB and a skilled woodworker. He built the bench/chest that acts as a top hatch, and adapted a set of IKEA cabinets to accommodate the bottom end. Both solutions work well in remodels and new construction.

Chute basics

I get requests for laundry chutes so often—sometimes midstream in the construction process—that I now ask clients if they want one when I review a set of plans. Obviously, it’s much easier to plan for a properly sized chute from the beginning. As a retrofit, one story is usually the limit, as it is much easier to cut through one floor than it is to send a properly sized chute from second floor to basement. The chute featured in this article drops from the main-floor master-bedroom closet into the basement laundry room below.

Clients want their chute to end as close as possible to the washer, so it’s best if you can make it terminate in or very near the laundry area. The top of the chute should go in the master bath or main hallway, with the latter affording easier access from other bedrooms.

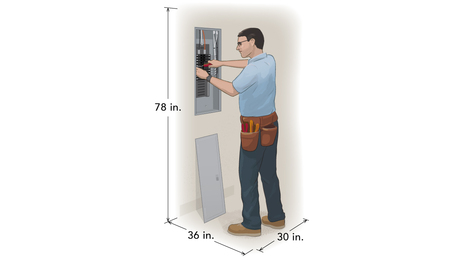

Dimensions also play a deciding role. Installing a laundry chute in the stud bay of a 2×4 doesn’t work. Socks and underwear will drop just fine, but larger items like jeans and sweatshirts will leave the client jamming a broomstick down the hole and cursing the contractor. I’ve found the ideal size is 12 in. by 12 in. Often this requires stealing space from a closet or elsewhere to install a chase. Sometimes clients won’t or can’t give up this much space, so I have to settle for 8 in. by 8 in.

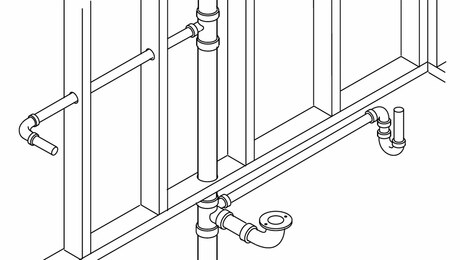

A laundry chute must be smooth, with no exposed joints or protrusions. Although I’ve tried drywall and finished plywood, I prefer metal ductwork because it’s smooth and quick to install. Also, it can be angled and formed to avoid obstacles. In new construction, I ask the HVAC tech to build the duct and I install it during the HVAC rough-in stage. Be sure to mark the installed duct with signs, so electricians and low-voltage techs aren’t tempted to use it for their own needs. For remodels, my local fabricator knocks out custom pieces at a fair price.

If you’re building a laundry or trash chute in a commercial building, get ready to decipher a host of code requirements. In the residential world, you must comply with IRC section 602.8, which addresses fireblocking. Basically, any penetrations you make for the chute must be headed off with approved materials. I typically fireblock with 2x framing lumber before installing the chute. An upstairs hatch is a minimum for blocking the actual chute in case of fire—and saving your cat from an unexpected ride. Having the bottom end empty out behind a cabinet or closet door will add a measure of soundproofing.

Building new

If you’re considering a laundry chute in a new home, there are two spots that often present the easiest path from upstairs to downstairs or the basement. I start looking near the main waste line coming from the master bathroom because it’s generally a 2×6 wall, but you’ll still need to make it deeper to accommodate an 8-in. or 12-in. duct. One way to do that is to steal space from a nearby linen closet.

With the chute starting in the wet wall, you often have the option to place the hatch in the master bath or an adjacent hallway. In both cases, I usually place the top of the chute in a small wall cabinet with a pull-down door, resulting in a hopper that makes loading easier. Another way to locate the upper hatch in the upstairs hall is to build a small chase into the back of a bedroom closet, stealing less than a foot of space with a flat-framed 2×4 wall.

Instant payoff

The new setup has improved life at the Christiana home in multiple ways. As promised, it makes laundry and wet workout gear disappear upstairs and reappear in a basket by the washing machine. What Asa didn’t anticipate is how the chute tames clutter on both floors, with no piles or baskets underfoot in either place.

Clear a Path for Clothes

Connecting the chute’s two levels starts with planning the route from upstairs to downstairs and searching for obstructions like pipes, ducts, or wires that would block the path.

Play it safe: Start with a pilot hole to confirm the chute will align as planned— if you’re wrong, a small hole is easier to fix than a large cutout. Use a long bit, and take care to keep it plumb to ensure you transfer the location accurately from ceiling to floor above.

Enlarge the hole: After confirming the location is correct, use a wallboard saw to enlarge the hole in the ceiling. Once this cutout is established, you can move upstairs to cut through the floor for the chute inlet.

|

|

Build the Upstairs Cabinet

Made from Russian birch plywood, this small bench houses the chute inlet, and its 3⁄4-in.-thick self-closing lid slows a downstairs fire from spreading upstairs. The completed bench is wide enough to seat two, creating the perfect spot to put on or take off a pair of shoes.

Sturdy skeleton: The bench is built around a frame of the same Russian birch plywood. Cut back the drywall and slide the frame into place against the studs to mark the duct location. Remove it again to cut out the back and add rails for the hopper.

Tapered hopper: Made from a combination of screwed-together 3⁄4-in. and 1⁄4-in. melamine, the hopper fits into the top of the duct and provides a larger opening at lid level. In this case, it also extends back into the wall cavity to reach the duct.

|

|

|

Build the Downstairs Cabinet

The chute outlet emerges from the bottom of a 36-in. wall cabinet from IKEA. The bank of cabinets provides a convenient spot for soap and other laundry products.

|

|

Finish off the bottom. The 5-ft. piece of ductwork is extended with a plywood box that carries the laundry through the bottom of the cabinet. The box is trimmed with mitered hardwood, which finishes off the cut in the cabinet bottom.

Ready for the washer. Clothes emerging from the chute land in a basket that can be carried to the washing machine. The counter creates the perfect spot for folding.

— Steve Pink, lead project manager for Hammer & Hand, a custom construction firm in Portland, OR and Asa Christiana, contributing editor and former editor of Fine Woodworking magazine.

From Fine Homebuilding #287

RELATED STORIES:

Published October 10, 2019. Updated May 8, 2024.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Affordable IR Camera

8067 All-Weather Flashing Tape

Reliable Crimp Connectors

View Comments

My 1955 home has a laundry chute in the base of a 24"w x 16"d broom closet in the hall just outside the bathroom. It is just a horizontal board about 8" up off the floor level that becomes the bottom shelf of the closet. Under this is a top hinged vertical flap. The nice things about this arrangement are the closet is still has 95% of its volume and dirty clothes are easily shoved into the chute with a foot - hands free!

Whatever the top flap for the chute is made from, I would explore how to provide a foot-operated level or pedal (like a waste basket) to flip the lid out of the way when dropping items into the chute.