Supporting Doors Over Foundation Foam

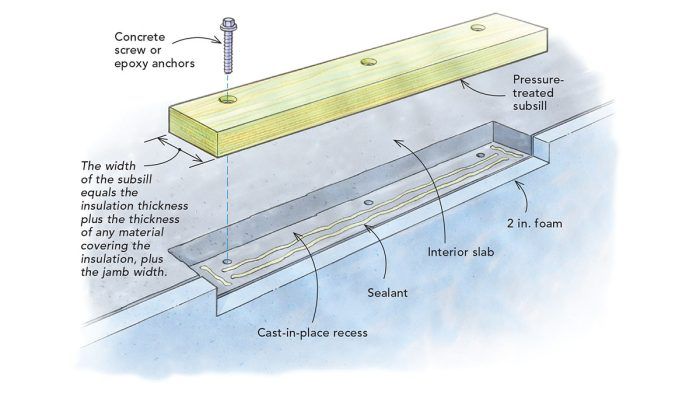

When setting exterior doors over a foam-insulated foundation, add a lumber subsill that will fully support the door.

I’m building a slab-on-grade house with 2 in. of insulation on the exterior face of the foundation walls that will align with the exterior foam on the framed walls above. I’m worried that the foundation insulation won’t support the door thresholds, and that the riser board beneath the front of the threshold won’t be of help since the fasteners will pass through the insulation. How can I provide solid support for the doors?

— Mike Y.; Lakes Region, N.H.

Editorial Advisor Mike Guertin Replies

The easiest way to support the door’s sill is to fasten a pressure-treated lumber cleat to the face of the foundation beneath each door and to cut the foam insulation around it. You could rip a 2-in.-thick strip out of a 4×4 to create the cleat.

However, my preferred approach is to make recesses in the concrete slab at each door for a lumber subsill to be fit into the recess later. The concrete crew can screw 2x blocks to the form that match the rough-opening width of each door at each door location. Later, pressure-treated blocks—ripped to the width of the recesses, plus the thickness of the exterior foundation insulation (2 in. in this case), plus the thickness of the material covering the insulation—can be fit and fastened inside the recesses. Be sure to apply sealant to block air leaks between the concrete and the blocks. You can use concrete screws or adhesive anchors to secure the blocks in place. I suggest using pressure-treated LVL as it’s less prone to splitting along the grain than sawn PT lumber. The sill pans for the doors can be applied to the top of the subsills after the walls are framed.

The subsill option takes a little more effort, but it removes less of the exterior insulation and provides a fully supported surface, making it less likely to shift than the face-fastened block, which relies on the shear and withdrawal strength of fasteners.

— Mike Guertin, editorial advisor. Drawing by Dan Thornton.

RELATED STORIES

- Windows & Doors Project Guide

- How To Build a Form for a Small Concrete Slab

- A Deep Dive Into Continuous Exterior Insulation

Need help?

Get answers you can trust from the experienced pros at FHB. Email your question to [email protected].

View Comments

Mike makes a good point, although I have a some additional considerations.

Very often the foundation walls for a slab on ground like this are formed and cast with block-outs at door openings. Then the floor slab is "over-poured" onto the resulting notch. This can create the the following issues:

IMHO most floor slabs are constructed too thin. 50+ years involved in the concrete industry has convinced me of this.

- The portion of the floor slab over the wall usually cracks more or less in line with the inside face of the foundation wall. This is due to the overall shrinkage of the floor slab.

- The subbase under the slab may not be adequately compacted and may slowly settle a bit over time - but the portion over the wall cannot. Result - another slab crack at the doorway.

- Fasteners. I would NEVER recommend the use of expansion bolts or concrete screw-type fasteners so close to any concrete edge. It can and does occasionally spall off a portion of the concrete near the bolt. My go-to would be threaded SS rods anchored using epoxy.

- Cutting a recess for the P/T lumber for the threshold may leave less than 3" of slab concrete to anchor it to. That thin layer of concrete may be easily cracked or spalled when drilling for the lumber's anchors.

- Yes, some may use TapCons, expansion bolts or concrete screws routinely and never experience an issue - that they're aware of. Have they been back 10+ years later to see how things are wearing?

My comments are based upon the assumption that this foundation does not utilize ICFs (insulated concrete forms).