Beam Stair

Make lifting heavy beams a breeze with a simple set of stairs.

In the course of adding a large family room to a house, we had to place a 22-ft. glulam atop an old stud wall to carry the weight of a couple of rooms above. The glulam weighed almost 500 lb., and we had no access for a crane, boom-truck or a forklift.

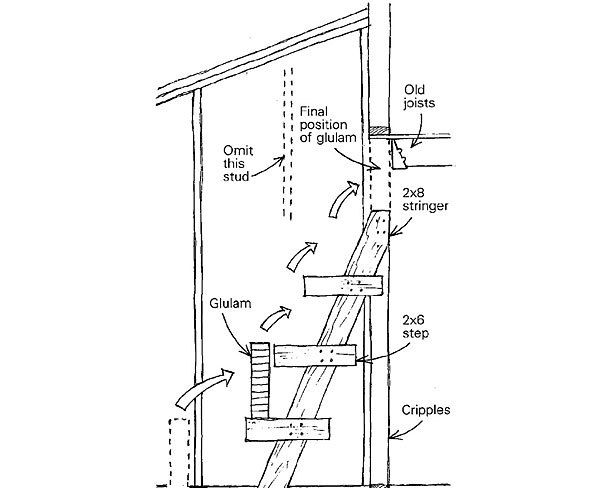

After easing the beast into the house with rollers and a temporary ramp that went from the driveway to the first floor, we devised what we called a “beam-stair” for making short lifts, one end at a time. Once the ceiling joists were temporarily shored up, we removed the old wall and nailed in three cripples on each side.

As we framed the adjacent walls, we left out a stud on each side for maneuvering room. In front of the double-width stud spaces, we built two temporary stair-step arrangements, dividing the height of the lift into four intervals of about 22 in. each.

As shown in the drawing, the stringer was a 2×8 affixed to the cripples with duplex nails and tacked securely at the bottom to the subfloor. The “steps” were 2×6 blocks, each about 18 in. long, secured to the stringer with four duplex nails apiece.

They were canted toward the stringer a bit, so the beam would tend to tilt a little backward toward the stringer rather than forward onto us. When the beam-stairs on each side were ready, we gathered three crew members plus the owner, and lifted one end of the beam at a time onto a step, and so on, until we had the beam sitting on the cripples.

One end of the beam was always supported, so we didn’t have to stagger with it free in the air. After a little more jacking, prying and shimming, we nailed it in place, added joist hangers for the second-floor joists we had previously cut, and took all the temporary stuff away.

— Robert Gay; Seattle, WA

From Fine Homebuilding #70

RELATED STORIES

Got a Tip?

Do you have any great tips like this one on how to make a simple stair for lifting heavy beams? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at tips@finehomebuilding.com, or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

Updated November 2024.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Protective Eyewear

Tajima Chalk Rite Chalk Line

Stabila Extendable Plate to Plate Level

View Comments

Clever, although I'm more than a little surprised that the duplex nails holding the "steps" to the stringers could take the weight and leveraging with such a small contact patch and such a long lever arm. Out at the end of the 18" "step" there would be 375 ftlbs of moment when the beam is first settled on the tip of the "step."

Wood's ability to tolerate 125% over typical allowable stress AND the conservatism built into fastener calculations comes as no surprise to me. I design temporary structures and for many applications we would allow 200 SWL per nail in single-shear. In most temporary situations, 1/32-1/16" of movement in a connection is no big deal.