Air Barrier Under Wood Paneling

To prevent moisture buildup and improve performance, install a continuous air barrier—such as drywall or specialized membranes—under tongue-and-groove boards or other interior wall paneling.

Where I build, wood paneling, tongue-and-groove boards, beadboard, fancy plywood, and even rustic boards with cracks are common. And don’t get me started on shiplap! Is it OK to just nail this paneling up on the studs and rafters, which is how I see it commonly done? This seems suspect to me. What is a conscientious builder to do behind this wood paneling for air and vapor control?

— Matthew Chrestman; Highlands, N.C.

Senior Editor Patrick McCombe Replies:

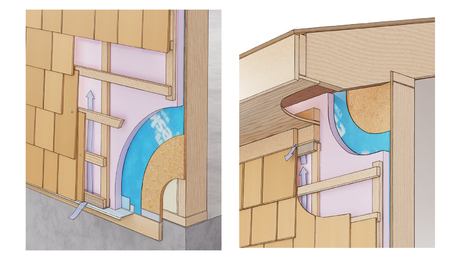

You’re right that installing wood paneling without an air barrier underneath it is suspect. Problems with these assemblies have been reported for decades. The biggest risk is during the winter in cold climates, where warm interior air moves through the cracks between boards, cools, and then condenses on the back side of the exterior sheathing.

The stack effect, HVAC systems, and air leaks create this air movement. If enough water accumulates on the sheathing, it will run down the stud cavity—often continuing into the basement or onto the floor—or drip through the tongue-and-groove ceiling. Many people first assume they have a leak.

Houses with paneled walls like you describe also have problems in mixed and cooling climates. Although seasonal drying from warmer temperatures and air conditioning may control wetting for years or decades, occupants might describe mold smells that come and go seasonally. Or problems may go unnoticed until insulation or HVAC-system upgrades change drying cycles, making mold or bad smells more apparent.

Don’t Make Assumptions

It’s sometimes assumed that installing a vapor retarder like poly sheeting over the framing or using kraft-faced batts will prevent air movement and vapor drive and the conditions described above. Canadian builders routinely build insulated assemblies with poly sheeting detailed as an air barrier, but poly and kraft insulation are not an effective air barrier as they’re commonly installed in the United States—and you need an air barrier more than a vapor-control layer to solve this problem.

Using poly and kraft insulation as an air barrier requires specific details so that they are continuous. This includes sealing them at top and bottom plates, electrical boxes, and other penetrations. Variable-permanence membranes from European manufacturers can also be installed for air and vapor control, assuming the same details.

Additional Options

Interior sheathing can also be detailed to be an air barrier under wood paneling with the added benefit of easy fastening for the paneling. But I think a layer of fire-taped drywall makes the most sense. Inexpensive and fire-resistant, it’s an effective air and vapor-control layer. And because most sound-control measures rely on mass, often drywall, I have to assume that a house with a drywall layer will also be quieter than one with other air barriers.

The drywall’s additional thickness requires site-made or custom extension jambs for doors and windows and also affects the rough-in of electrical boxes, register boots, and plumbing fixtures. Have subcontractors account for the extra wall or ceiling thickness when roughing in, or electric devices, HVAC registers, and plumbing fixtures may not fit at trim-out. All of this may sound like a hassle, but I think the energy and comfort benefits, fire-resistance, and additional quiet make the effort worthwhile.

From Fine Homebuilding #329

RELATED STORIES

- Airtight Wall and Roof Sheathing

- Air-Sealing a High-Performance House

- Foundation Air and Vapor Strategy

Need help?

Do you have more questions about air barriers under wood paneling or something else? Get answers you can trust from the experienced pros at FHB. Email your question to [email protected].

View Comments

Hi, I recently built an addition onto my house and used closed cell insulation in the stud bays and rafter bays. We installed interior nickle gap siding right over the new framing,

is that going to be a problem? Isn't closed cell a vapor barrier?