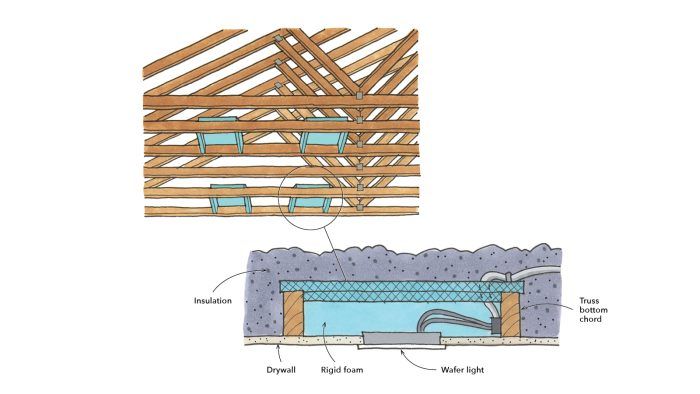

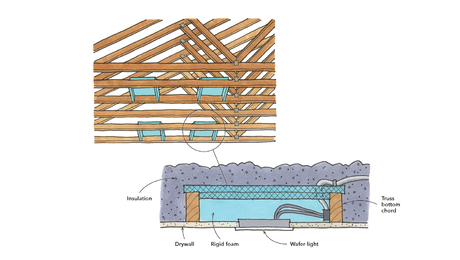

Insulation Shield for Wafer Lights

Creating a sealed cavity with rigid foam ensures the insulation in the ceiling remains intact.

Wafer lights are faster to install and less expensive than recessed can lights. However, when you try to install (or replace) them on a drywalled ceiling that has an insulated attic above, you end up with a face full of insulation and voids in the thermal envelope.

To prevent this, I create a shield out of rigid foam. I sandwich together two sections of foam boards—one sized to fit between the bottom chords on the roof trusses, and a longer one to sit on top of them. I then add sides to create a sealed cavity once the drywall is in place. I hold the foam together with panel adhesive and nails and secure them in place with a dab of adhesive.

— Mark Petersen; Waco, Ky.

RELATED STORIES

- The Science and Art of Better Home Lighting

- Downlights for Every Budget

- How to Get Airtight Recessed Lighting Every Time

Got a Tip?

Do you have any great tips like this one on how to make DIY insulation shields for wafer lights? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at [email protected], or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Caulking Gun

Great Stuff Foam Cleaner

Insulation Knife

View Comments

I like your tip. But when it's not a truss situation up there in the attic, I'd do the upper layer in plywood instead of the second layer of foam. Otherwise, Murphy's Law tells me that someone in the attic is bound to put a foot through the whole thing.

The illustration shows the LED driver J-box attached to the joist. From experience, I recommend leaving it loose, lying on the drywall (which requires leaving the pigtail loose and installing the driver box and wafer light after paint.

The reason to do this is that wafer lights have 2 potential failure points, the wafer LED itself and the LED driver box. If the driver is attached to the joist you have to wade through the attic insulation to pull the box off the joist and replace it, unless you can lever it off through the 6" wafer hole. If it's out in the skinny part of the attic, access from above may be nearly impossible.

To keep the drywallers from pinching the loose end of the pigtail between the ceiling and a joist,, staple it loosely to the joist, so you can pull it out at finish electric. And don't just think about installation, think about service.