Installing Prefinished Cabinet Molding

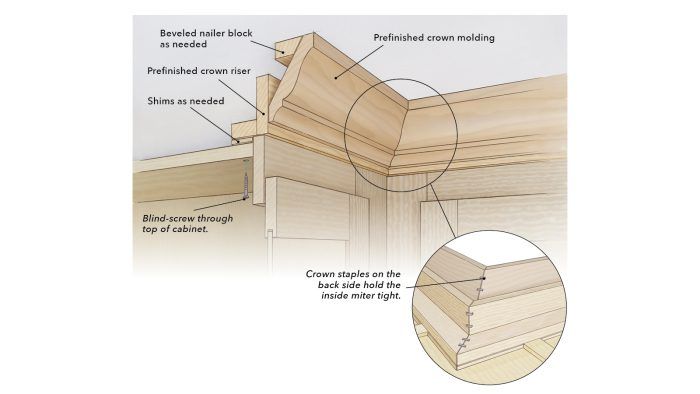

Use these assembly techniques when installing crown risers and molding to minimize visible gaps and nail holes.

It seems that cabinet trim like crown molding is almost always prefinished along with the cabinetry before it’s delivered to the job site. This makes installation difficult, as often the moldings cannot be caulked and filled the same as trims that will be finished in place. How do professional carpenters get good-looking results when installing prefinished moldings?

— Greg Boyd; Cape Vincent, N.Y.

Master Finish Carpenter Corey Mercer Replies

To install the best-looking prefinished moldings, a carpenter’s overall goal should be to eliminate gaps or joints that require caulk or filler while also minimizing the amount of nail holes required to be filled. The first key to installing prefinished crown molding on kitchen cabinets is crown riser. Crown riser is the L-shaped piece of molding that is installed around the upper perimeter of the cabinetry, and which provides a surface for the lower edge of the crown molding to rest on.

This is important when crown will be installed against the finished ceiling, as it provides a taller area for the crown to rest than the upper frame of the cabinet alone, giving the installer some flexibility on the height of the top of the cabinet. Plus, the larger reveal between the crown’s bottom edge and the riser’s bottom edge helps hide minor variations in alignment when a ceiling isn’t perfectly flat or level, which is often the case.

Crown riser is typically installed flush to the cabinet edge or slightly overhanging to create a pleasing reveal line against the cabinet. If the riser is shipped in two pieces, I glue and screw from the back of the horizontal portion of the L so there are no visible nail holes on the front side.

Once it’s assembled, I screw the horizontal leg of the riser to the cabinets and then glue and nail the corners. As the cabinets are normally already in place before I install the riser, I like to blind-screw the riser up through the top of the cabinet, placing shims as needed to account for any inset between the top of the case and the top of the face frame.

Installation Methods

You can cut and install the prefinished crown piece by piece, or preassemble the pieces and install them in larger sections. I typically do a hybrid of the two, installing most of the molding piece by piece but preassembling inside corners. I like to preassemble the inside corners because I can glue and fasten the miter from the back side.

Assembling outside corners piece by piece allows me some flexibility to adjust the individual pieces to keep the miter tight on the corner as I glue and fasten it in place. And when the ceiling isn’t flat, scribing the top edge of the crown to meet the ceiling to avoid an unsightly gap is much easier with individual pieces. If your crown is especially large, attaching some blocks to the ceiling can provide a nail backing for the top edge to securely fasten the crown in place.

To get even more technical, I prefer to use a non-sliding compound dual-bevel miter saw for most installs, switching only to a sliding saw when the crown or riser is too tall for the non-sliding capacity. A non-sliding saw is inherently more accurate than its sliding counterpart, as the blade will experience less deflection during the cut.

I usually don’t do much with crown-cutting jigs or crown stops, and prefer to tape or draw a line on the saw fence as a reference to hold the correct nested angle every time. Whichever method you choose, the key point is to make sure you have a repeatable reference for nesting your crown on every cut in order to maintain your joint accuracy.

More to Consider

Gluing your joints is especially important to keep them tight and good-looking over time. I often use a PVA wood glue such as Titebond for corners, although some carpenters use cyanoacrylate adhesive (CA) glues with accelerators, such as 2P-10 or Starbond, with excellent results. I think traditional PVA glue makes a slightly stronger finished joint than CA glue, and its slower set also allows for extra adjustment time while assembling pieces in place. (The speed of CA does shine when you’re assembling small returns with no fasteners.)

I like to use an 18-ga. nailer, as it offers a good trade-off between holding power and size of hole, but I reserve a 23-ga. pin nailer for delicate pieces or returns. A middle ground for prefinished work is a 21-ga. pneumatic nailer, which leaves smaller nail holes to fill than 18-ga. brads, but provides more holding power than pins.

The only drawback is that 21-ga. nailers are typically pneumatic only, making them less than ideal in a cordless-dominated workflow (Grex is currently the only company to make a 21-ga. cordless nailer). Finally, a staple gun with 1/2-in. crown staples is handy for blind-fastening inside corners from the back side when preassembling the crown, as the legs on the staples are wide enough apart to span the joint and hold both pieces tightly together as the glue cures. Just make sure to use staples that are short enough not to blow out the front of the material.

Careful and thoughtful nailing is key to minimizing the amount of nail holes. Most cabinet manufacturers include a wax fill stick to fill nail holes. If needed, this can be applied to the mitered corners as well—just heat the stick a little with a lighter, smear the wax into the hole or miter, scrape off the excess, and polish with a dry rag. Some manufacturers also have touch-up pens available depending on the finish, which I would recommend coordinating when you order.

RELATED STORIES

- 10 Steps to Install Crown Molding on Cabinets

- 10 Essentials for Quality Trim Carpentry

- Installing Semicustom Kitchen Cabinets

Need help?

Do you have more questions about installing prefinished cabinet molding or something else? Get answers you can trust from the experienced pros at FHB. Email your question to [email protected].