Fight House Fires Through Design

Smart construction decisions and material choices can significantly improve occupant safety and survival in the event of a fire in the home.

Modern homes are more dangerous in fires than ever before, but thoughtful design and material choices can drastically improve survival outcomes. Builder and firefighter Grant Baver outlines practical strategies — from protecting engineered lumber to using noncombustible insulation, thicker drywall, and enhanced fireblocking — that all go beyond minimum code to better protect lives. The article emphasizes the life-saving power of closed doors, interconnected detectors, and automatic sprinkler systems, which dramatically reduce fatalities and injuries. It also warns against the use of vulnerable materials like unprotected CSST for gas piping.

Understanding Residential Fire Safety

In 2023 alone, the National Fire Protection Agency (NFPA) reported an estimated 470,000 structure fires resulting in 3070 civilian deaths, 11,790 civilian injuries, and a staggering $14.7 billion dollars in property damage, making fire one of the leading causes of accidental death and property loss across the country. House fires today, although less numerous than in the past, are deadlier than ever. Compared to 1980, the death rate per 1000 one- and two-family house fires has increased from 7.1 to 9.7—a frightening 37% increase.

In my work as a residential builder, reflecting on my role and education as a firefighter has made me realize that many of the trends in modern residential building construction, such as elevated fuel loads, lightweight construction methods, and modern design (for example, open-concept floor plans), have detracted from residential fire safety.

While these decreases in safety have been mostly inadvertent side effects, if we truly want to increase residential fire safety and survival, we must start thinking about it as a primary consideration in the design and execution of our projects, rather than an afterthought that can easily be pushed aside for reasons such as cost or resistance to change.

Over the next few pages, I discuss several important fire-safety considerations. Some of them are tailored to new construction, and some apply to renovations and everyday home maintenance. Some are as easy as following the code, while experience suggests for others that the minimum code isn’t good enough.

Some are based upon my personal observations and experiences as a firefighter, while others are deeply rooted in scientific study and statistics. But every point that follows has one thing in common: If given proper attention and implemented well, each will contribute to a safer home. We owe it to our clients as builders and architects, and to our families as homeowners, to improve our practices and decision-making when it comes to residential fire safety. It just might save someone’s life.

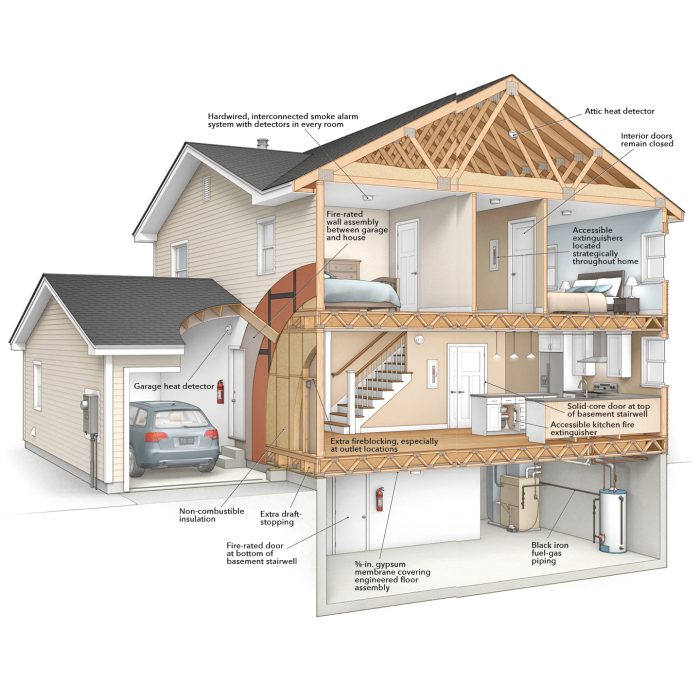

Details for a Fire-Smart Home Every level of a home presents opportunities for making design decisions that will have impacts on the fire safety and survivability of the people who live there. While there is no substitute for the ultimate fire-protection measure for a home—a sprinkler system—deciding to include these important elements in a structure, even if its non-sprinklered, will help save lives and property in the event of a fire. Installing doors that provide separation between different spaces and levels of the home, and keeping those doors closed, significantly reduces fire propagation while also protecting escape paths and providing areas of refuge for residents. Detailing and installing fire-protected floor assemblies helps to maintain the structural integrity of the diaphragm both for escaping residents and incoming firefighters. Reducing the fuel load and fire resistance of the building materials provides a potential fire with less available fuel to grow and spread. Finally, having interconnected smoke alarms in all areas of the home provides early detection and early occupant warning. |

Engineered Lumber’s Number One Enemy Is Fire

While engineered lumber and truss systems are often celebrated for their remarkable strength-to-weight ratio and their ability to span long distances, they have also developed a reputation in the fire service as “fireman killers,” and for good reason. When unprotected assemblies of engineered structural members are exposed to heat and fire, they fail significantly faster than their solid-sawn counterparts.

In a 2012 report by the Fire Safety Research Institute (FSRI, a UL Research Institute), results of an experiment evaluating full-scale samples of different unprotected floor systems marked minimum catastrophic failure/collapse times of 3:28, 6:00, and 11:09 for engineered floor trusses, I-joists, and solid-sawn 2×12 assemblies, respectively. To give these numbers some perspective, the average fire department response times usually hover between four minutes to 12 minutes depending on location and type of fire service.

Engineered lumber does have its place in construction, but if you are going to use it, you must protect it properly. The best protection for any non-sprinkler-protected floor system is a continuous gypsum membrane on the underside, with sealed penetrations. (Sprinklers are by far the best method of floor protection, and I talk about them later in this article.)

Although the International Residential Code (IRC) has had provisions since 2015 in section R302.13 requiring protection (such as ½-in. drywall) over the bottom of floor systems, many houses are able to avoid this requirement by hiding behind its exceptions. There are still houses being built every single day without the lifesaving feature of protected floor systems, because improper code exceptions allow it.

Forget what the code says and let me make this incredibly easy to understand: For optimal fire safety, all floors, whether they are engineered or not, should be protected either by a fire sprinkler system or by a continuous gypsum membrane of at least ½ in. (or a wood structural-panel membrane of at least 5/8 in.).

In the same 2012 report meantioned earlier, FSRI also shares data for a previous experiment conducted on three similar floor assemblies, this time protected by a ½-in. gypsum membrane. The results speak volumes, with the data set showing increased collapse times for protected assemblies of engineered floor trusses, I-joists, and solid sawn 2x10s of 29:15, 26:45, and 44:40 respectively. (When a similar experiment was conducted with each of these floor types protected by a sprinkler system, structural failure and collapse could not be reached.)

Modern Products for a Fire-Smart HomeIn the vast sea of home construction products, the following are just a few of the ones that stand out for their innovation and commitment to furthering residential fire safety.

|

Photos courtesy of the manufacturers

Noncombustible Insulation Limits Fire Growth and Spread

A commonly used term in fire dynamics is fuel load. Fuel load refers to the amount of combustible material that is available for a fire to consume, which in the context of a typical residential structure fire is the combination of the contents of the building and the wood-framed building itself. One of the most basic strategies for eliminating, controlling, or extinguishing fire is fuel removal. By reducing the use of construction materials that act as combustible fuels, you also reduce the contribution to the fuel load by the building itself.

Likely the easiest way to reduce fuel load in common assemblies is by making smarter insulation choices. By utilizing noncombustible insulation in place of combustible alternatives, you can greatly reduce the amount of fuel available to a fire that has spread into the building itself, which will help to stunt the fire’s growth and further spread.

Here are examples of how this applies to both interior and exterior insulation. When the point of origin of a fire is within the wall cavity itself—for example, a sparking electrical outlet—having that point surrounded with noncombustibles will limit fire growth and may even prevent further fire development in the first place. On the flip side, when it comes to exterior insulation, combustible foams can provide a superhighway for incidents like a backyard BBQ grill fire to very quickly travel up the side of the structure and extend into the attic or another part of the building enclosure.

Mineral fiber or mineral wool is often the first choice when it comes to noncombustible insulation, as it is fireproof by nature. However, treated cellulose, unfaced fiberglass (faced fiberglass is tricky, as the facer is usually combustible), and some treated wood-fiber insulations are also possible options. Examples of combustible insulations to avoid are spray foams, unfaced rigid foams, and untreated cellulose.

Spray foam and unfaced XPS, from a fire safety point of view, are particularly unfavorable, as they are not only generally combustible but also release highly toxic and dangerous gases when they do burn. If you must use rigid foam, remember that some versions (polyiso) are typically faced with a foil ignition barrier, which does provide some level of flame resistance, making them a better option than their unfaced cousins.

Don’t Underestimate Thicker GWB

Gypsum wallboard (GWB), more commonly referred to as drywall, is the backbone of most fire-rated wall assemblies. While all thicknesses and classifications of drywall are, at least to some extent, able to resist intense heat and fire, two special types of drywall (Type X and Type C) are formulated with special additives to improve fire resistance even further. In residential construction, 5/8-in. Type X is generally the most common type of fire-resistant drywall (see “What’s the Difference: Fire-Resistant Drywall” in FHB #193).

Except for some specific locations where fire-resistant drywall is required, most IRC minimum GWB requirements are met by typical ½-in. panels. While standard ½-in. panels do offer some fire resistance, the simple fact is that 5/8-in. Type X panels perform much better when it comes to stopping the spread of fire.

As a benchmark, you might expect a partition clad with 5/8-in. to provide approximately 60 minutes of fire separation, while the same partition with ½-in. would only provide about 30 minutes. This comparison of thicknesses and fire-separation times isn’t completely accurate, as residential walls often aren’t detailed as true fire walls, but debating that point detracts from the important takeaway. A typical fire can double in size every 30 seconds to 1 minute, so even if the difference in performance is only five minutes, that five-minute increase could be of lifesaving significance.

Finally, the cost difference between hanging an entire house with ½-in. vs. 5/8-in. drywall is so minimal in relation to the significant difference in fire performance. After a quick takeoff of a 1500-sq.-ft. house with about 6000 sq. ft. of wall and ceiling area, the difference in drywall material between ½-in. ultralight and 5/8-in. Type X was between $300 and $400 total, including stocking fees. At the absolute minimum, be sure to use 5/8-in. Type X in critical areas like garage walls, mechanical rooms, basement ceilings, and kitchens.

Fireblocking Is Cheap and Effective

Over the years, Fine Homebuilding has thoroughly addressed the topics of fireblocking and draftstopping. Most recently, “The what and where of fireblocking” (Know the Code, FHB #325) and “Slow the Burn” (FHB #296) include details of fireblocking requirements, locations, and installation.

Increasing a home’s fire safety with fireblocking is simple: Be assiduous in nailing the code requirements, and then add more. Given that fireblocking is extremely cheap to install, I don’t believe there is such a thing as too much fireblocking. After all code-required fireblocking is installed, consider giving a proficient carpenter one extra afternoon with a circular saw and a nail gun, a case of fire caulk, and access to the sheet-good scraps and cutoff pile. For the couple hundred bucks of extra labor, your building’s ability to resist the spread of fire will be considerably improved.

Simple actions like adding an extra fireblock in every stud bay that has an electrical box and sealing holes around wires and pipes that run through studs from bay to bay can be the difference between an outlet malfunction and a two-alarm house fire. Add draftstopping in ceiling/floor assemblies, even if the area is small enough to not require it by code. Seal around pipes, wires, and ducts running through floor systems. Install vertical blocks between the back of your basement walls and the foundation at 5-ft.-horizontal intervals instead of every 10 ft. You get the idea.

Closed Doors Save Lives

Flow path, in the terms of a typical fire, is established by the hot smoke and gases (high pressure) ventilating to the outside of the building or compartment (low pressure) as fresh air (high pressure) is simultaneously drawn into the flaming combustion (low pressure). Door control is a critical strategy used to eliminate and control flow paths.

It’s a no-brainer: By keeping doors closed, you limit the possible flow path of spreading fire, keeping the occupants behind those doors safer. In fact, there is an advanced strategy in firefighting known as VEIS (vent, enter, isolate, search) based on the concept of isolating compartments within a structure by closing interior doors.

Even the most basic of hollow-core doors, when closed, will hold back a surprising amount of fire. A very simple way to upgrade a home’s fire safety is upgrading your doors. Utilizing solid-core doors, even if only in key areas like bedrooms, basements, and mechanical rooms, will help control the spread of fire either out of or into those areas for a longer time period than a hollow-core counterpart.

Additionally, stair openings (especially basement stairs) are notorious for becoming the flow path for fire spread between levels of a house. Isolating stairwells at both the top and bottom, even with hollow-cored doors, can significantly hinder fire from jumping levels. You can even take it a step further by upgrading to fire-resistant doors (the most common in residential construction having a 20-minute fire rating, which is already required between a garage and living space), especially at areas like basements and mechanical rooms.

Closed Doors Can Save Lives Keeping doors closed is so critical to saving lives and property in the event of a fire that the Fire Safety Research Institute (FSRI) has dedicated an entire public education program to door-control awareness known as “Close Before You Doze.” Considering that an occupant has just three minutes to escape a house fire today, compared to about 17 minutes 40 years ago, FSRI hopes the message will become the ubiquitous modern safety mantra that “Stop, drop, and roll” was in the past. Simply put, if you are trapped in a house fire and cannot get out, closing your door is the single most impactful action you can take to save your life. Explore more at closeyourdoor.org. |

Don’t Skimp on Smoke Alarms

Most people have heard the saying “Smoke alarms save lives,” and for good reason. From 2018 to 2022, an NFPA study reported that the death rate per 1000 fires in homes with functioning smoke alarms (5.8) was 60% lower than in homes without functional smoke alarms (14.4). Furthermore, fires in homes without functioning detectors accounted for 59% of all fire fatalities over the time period.

First and foremost, making sure your alarms are interconnected is critical. This helps to provide early warning to occupants of fires in other areas of the home, allowing them more time to escape. “The Right Spots for Smoke Alarms” (Know the Code, FHB #329) provides a deeper look into code requirements for smoke alarms.

As with many of the things discussed in this article, it’s a worthwhile upgrade to exceed code and use combination smoke–carbon monoxide alarms at all alarm locations. If you have combustion appliances on any level of the home, including exterior appliances that are within close proximity to the house, this is an essential upgrade to prevent potentially deadly carbon monoxide emergencies.

Even though it’s not required by code, alarms should also be installed in attics and garages. Heat detectors, also known as rate-of-rise detectors (ROR), typically have a much larger operational temperature range than traditional ionization and photoelectric smoke detectors/alarms, making them suitable for installation in these unconditioned locations.

I recall an attic fire that went completely unnoticed by a family going to bed, as the smoke alarms in the home never activated. Thankfully, one of the children happened to get out of bed to go to the bathroom and heard a “weird crackling sound” in the ceiling, allowing the family just enough time to evacuate the house and remain safe.

Suppression System Statistics Don’t Lie

Installation of automatic extinguishing systems (AES), more commonly referred to as sprinkler systems, is a highly debated topic in the industry. Opponents litter the conversation with arguments that sprinkler systems are too expensive or burdensome to install and that smoke alarms are enough. Although the requirement for sprinkler systems to be installed in single family residences first appeared in the code in the 2009 IRC (section R313.2), to date only two states have actually adopted this requirement.

As members of the residential construction community, we need to face the facts about sprinkler systems. Statistics and practical experience demonstrate that they work—exceptionally well. A 2024 NFPA report shows that the civilian death rate per 1000 home fires was a remarkable 89% lower in homes with AES (0.9) than in homes without AES (8.3).

Furthermore, civilian injury rates, firefighter injury rates, and rate of property loss in homes with AES were also all greatly reduced by 31%, 48%, and 55%, respectively. Finally, 86% of deaths and 84% of injuries were limited to the room or object of origin in homes with AES, versus only 18% of deaths and 49% of injuries in home fires without AES.

Sprinkler systems are the only active method of fire protection talked about in this article, meaning that they are the only measure that can actively work to contain and extinguish a fire that’s already started. Furthermore, residential sprinkler systems are constantly improving their ease of installation and reducing the barrier to entry.

One newer system, Uponor AquaSafe, uses traditional piping methods tied directly into the domestic water supply. Since the manufacturer also handles the necessary system engineering, it can even be installed by your regular plumber. If you truly want to protect the occupants of a home and significantly increase their chances of noninjury and survival in a structure fire, install a sprinkler system.

Fire-Smart Fuel-Gas Piping

Corrugated stainless-steel tubing (CSST) is a flexible fuel-gas piping product that is being increasingly installed in place of traditional black iron fuel-gas piping systems in residential construction. While CSST is typically faster and less labor intensive to install than traditional black iron systems (especially threaded systems), it also can become significantly more dangerous than its traditional counterpart. One major issue with CSST is its susceptibility to developing arc holes when subjected to a ground-seeking electrical charge, most commonly a lightning strike.

Most recently, two firefighters were tragically killed in Maryland in two separate yet very similar incidents where electricity from lighting strikes (one from a tree in the backyard of the property) caused arc holes in CSST tubing, igniting hidden blowtorch-like fuel-fed fires, which caused catastrophic floor collapses. Some manufacturers make arc-resistant CSST tubing, which has a special protective jacket to help eliminate the possibility of arc holes. If you must use CSST on your project, make sure to use an arc-resistant product that’s properly installed and bonded.

Unless you are in an area of seismic activity (the only scenario in which I’d recommend arc-resistant CSST), I advise sticking to traditional black-iron fuel gas systems. Not only is black iron more durable and resilient to punctures and damage, but it also typically has a significantly lower developed length of piping, which means there is less overall opportunity for leaks or damages. Finally, black iron fuel-gas systems, both threaded and MegaPress, are usually required to be installed by a skilled, licensed plumber in most regions in the United States. This adds a level of quality control in assuring the installation is done safely and correctly, and per the fuel-gas code.

Smart Mechanical Design Eliminates Common Hazards

Covering all the nuances of mechanical designs and how they interact and relate to fire safety could be the topic of a book. However, there are a few basic tips to consider when designing or renovating that will help to minimize some of the most common causes of fires. First, home heating (specifically space heaters) accounts for about 13% of fires annually.

Designing HVAC systems in smarter ways to increase occupant comfort, such as using multiple zones or balancing air systems, can help limit or eliminate space heater usage. Electrically, adding extra outlets in commonly used areas eliminates the need for extension cords, and keeping the number of outlets per circuit low by adding extra circuits keeps components from overloading and overheating.

Fire Extinguishers Should Not Be an Afterthought

Considering that nearly half of all home structure fires are caused by cooking, and many of those incidents begin as small fires, having a fire extinguisher close at hand in a kitchen is paramount. Sadly, many homeowners and builders treat the fire extinguisher placement or mounting as an afterthought.

I can’t begin to count the times I’ve seen a fire extinguisher shoved under the kitchen sink, leading to the resident being unable to locate it in the moment of panic when a fire breaks out. One way to solve this problem is to consider having a dedicated fire extinguisher location built right into your cabinets. We build in every other manner of item into cabinetry—garbage cans, pet bowls, and spice racks—so why not build in a holder for your fire extinguisher so you can locate and access it quickly if needed?

The same goes for placement of fire extinguishers. Placing fire extinguishers in inconspicuous spots around your house and knowing how to locate and use them in an emergency might prevent a major structure fire. A great way to accomplish this while maintaining style is by using recessed or semirecessed extinguisher cabinets in areas like laundry rooms, mechanical rooms, and garages. The best way to be sure you are always prepared is by building fire safety right into the house.

— Grant Baver is FHB’s associate editor and a firefighter in Berks County, Pa.

RELATED STORIES

- The What and Where of Fireblocking

- Designed for Wildfire Country

- Building to Help Withstand Wildfires

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

All New Kitchen Ideas that Work

Not So Big House

Code Check 10th Edition: An Illustrated Guide to Building a Safe House