Rammed Earth: Creating a 500-Year House

A design-build team demonstrates the durability of an ancient material.

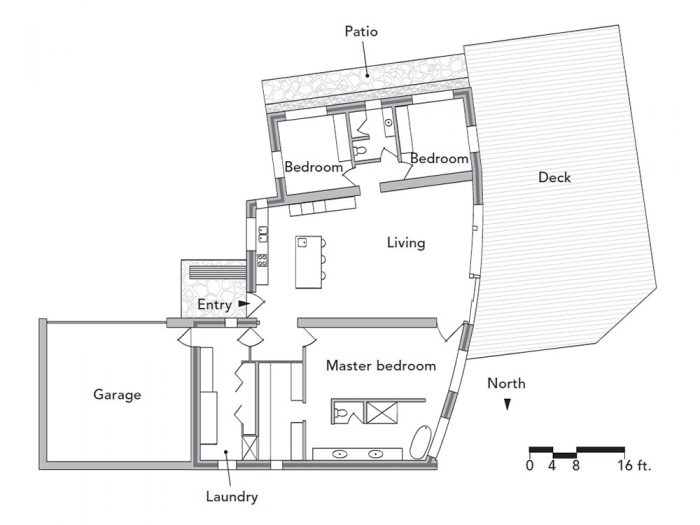

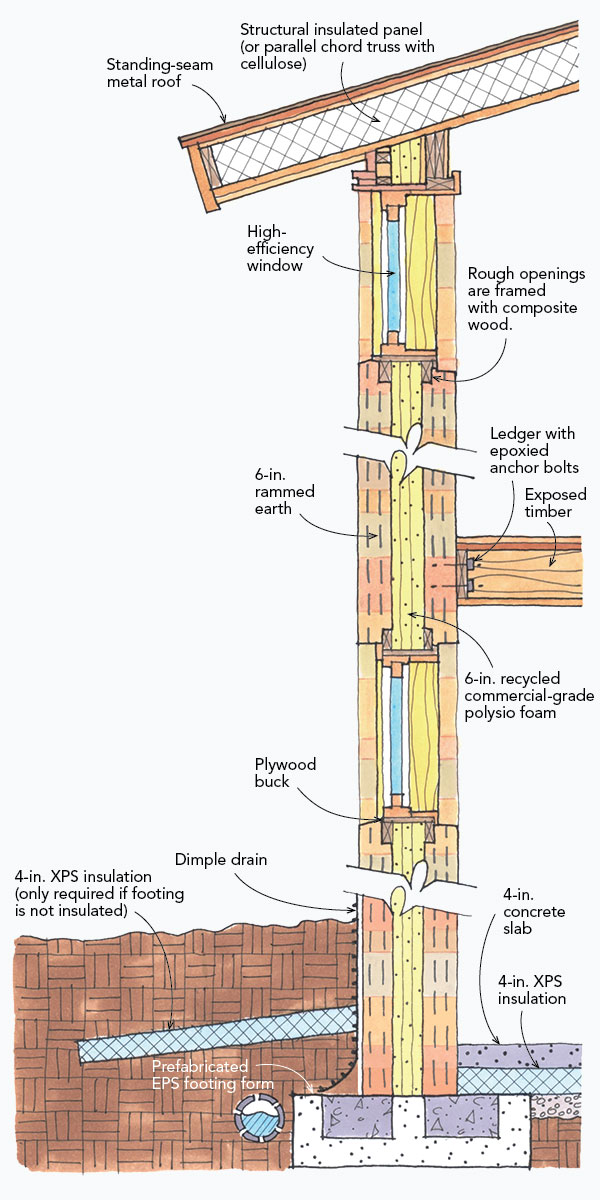

Synopsis: Rammed-earth construction has many benefits, including low embodied energy, recylability, low energy loads, and longevity. This article describes the technique of building with rammed earth, including a section drawing of a rammed-earth wall assembly. Terrell Wong and Sylvia Cook, specialists in the design and construction of rammed-earth homes, describe the benefits of working with rammed earth, and explain that it remains a fringe method due to lack of both knowledge and building codes in the United States. The article includes a case study of a rammed-earth home, including floor plans and descriptions of the advantages of building with rammed earth, from maintaining consistent temperature and inhibiting mold growth to aesthetic beauty.

The rammed-earth construction technique is several thousand years old and is thought to have originated independently in both China, where original rammed-earth sections of the Great Wall are still standing, and the Iberian Peninsula. Other examples include the Hakka Tulou—a series of five-story round apartment buildings in China—and the Alhambra palace in Spain.

The technique has a lot to recommend it. The green-building benefits include low embodied energy, recyclability, high thermal mass/low energy loads, and nontoxicity. For those reasons, Terrell Wong, principal of Stone’s Throw Design in Ontario, Canada, is a fan of the material and the method. She also appreciates the durability and longevity of rammed-earth houses. When describing rammed earth to her clients, Wong says, “It is the structure, the insulation, the finish, and the thermal mass for a building. It will never need painting, and it will last 500 years, if not more.”

Wong’s rammed-earth walls are built in panels approximately 11 1/2 ft. long, and the material is a mix of 20% to 30% clay, sand, and 5% to 10% cement. In cold, wet climates, a silicate-based waterproofing agent is often added. The walls are constructed in place in lifts, and 1 ft. of material is layered into formwork and compressed down to 6 in. with a pneumatic tamper. The forms are about 20 in. wide and 4 ft. tall, often built of HDO plywood and dimensional and engineered lumber. When a wall is more than one panel long, a recess is added to one end of the first panel, and the second panel is molded into that space, locking them together. Conduit for pipes and wires are added during the process, and it’s important to know where conduit and windows are going because they can’t be moved once the wall is up. Typically, walls are done and dry in 24 hours, with a load-bearing capacity on par with concrete.

For the past 10 years, Wong has designed three to four rammed-earth houses per year. She says it’s still something of a fringe method in Canada, and notes that there are just a few builders doing rammed-earth construction in all of Ontario. One of them is Sylvia Cook, principal of Aerecura Rammed Earth Builders. Though rammed earth is often said to work best in arid climates, Cook makes this point: “The thermal-mass effect works equally well for hot climates, where heat gain is delayed, and for cold climates, where heat loss gets shifted from the middle of the night to the middle of the day, when the sun makes up the difference. This keeps the temperature consistent year-round. Our belief is that it remains a ‘fringe method’ due to lack of knowledge of the system.”

Rammed-earth walls are also notable for their earth-toned striations. To get that look, pigment is added to the cement, which the ramming process moves to the edges of the board form so the colors are visible on the wall’s outermost layer. “You get this natural umbrage of color,” says Wong, adding that those waves can be exaggerated by varying the amount of material in each layer.

Building up, packing downKey to a rammed-earth home’s success are the reusable forms that support the build, which are made of HDO plywood and dimensional and engineered lumber. The whole form is braced to keep walls square, level, and plumb during the pour and ramming; metal footings with turnbuckles enable the bracing to be tightened and loosened, as needed. Aerecura uses test cylinders filled with rammed earth to measure psi prior to and during the build in order to meet engineering codes. |

Though rammed-earth construction has been modernized, North America has not adopted building codes for it. “In Canada, we use a solution that demonstrates rammed earth meets code requirements because it is much like concrete or concrete block,” Wong explains, adding that in colder, wetter climates rebar is needed to reinforce structures. She also integrates recycled polyiso insulation into the middle of rammed-earth walls to minimize thermal bridging. In Australia and New Zealand, where rammed-earth houses are more common, codes have been formalized. In fact, research conducted in earthquake-prone New Zealand suggests that monolithic earth walls withstand earthquake conditions better than brick or block walls.

Predictably, the complexity of a project influences cost—curved or angled walls are going to be more expensive than their conventional counterparts because the rammed-earth method is labor-intensive. But by keeping the design and formwork simple, Wong was able to use the method for an affordable housing project.

From FineHomebuilding #289

To view the entire article, please click the View PDF button below.

More about green-building:

Rammed Earth Construction – One of Ontario’s first insulated rammed earth home is a testament to the method’s attributes.

Vernacular Architecture & Sustainable Design – Architect Janet Harrison views incorporating regional forms and materials as the first step toward green building.

What’s the Definition of “Green Building”? – Energy Nerd: 10 factors for eco-friendly home design, analyzed.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

100-ft. Tape Measure

Original Speed Square

Plate Level