On the Edge

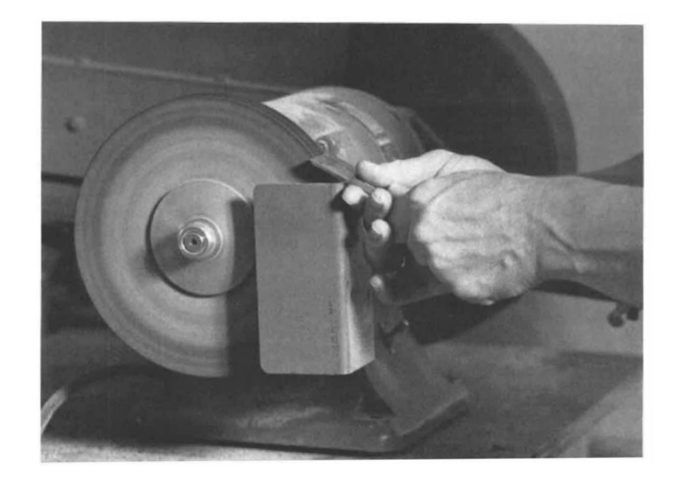

An overview of grinding and honing for the carpenter, wherein the author argues for more skill and fewer gadgets.

Synopsis: Sharpening edge tools is a necessary part of working with wood. In this article, the author, a cabinetmaker, outlines a simple approach to grinding and honing chisels, plane irons, and other tools without any complicated jigs. His methods might seem too elaborate for some carpenters, but they produce very sharp edges quickly and are worth considering.

I revered my Arkansas stones, until I met Apolinar. He worked as a carpenter in a Texas shop that made custom doors, windows, interior trim and furniture for rich clients. He came across the river from Mexico, where the guild system that followed the conquistadores into the New World still spawns craftsmen who serve out formal apprenticeships. Apolinar at the age of 50 was a master of his trade, with a measure of self-esteem to match his skills. He could not be coddled or coerced into sweeping the floor, he thought it entirely beneath his station to maintain or adjust any of the machines in the shop and he steadfastly refused to use sandpaper. He got paid by the piece, worked his own hours, and made about six times the money he would have earned in his native Mexico City. Not bad for an illegal alien.

Apolinar didn’t have any whetstones. Yet his chisels and plane irons were always impeccably sharp. Nobody ever saw him sharpen a single tool, yet every morning there they were, freshly honed and ready for another day’s service at the bench. One night when I was working late, I noticed Apolinar fussing around his bench in an unaccustomed way. He was getting ready to go home, and kept acting like he’d forgotten something. Finally he gave a demure grin and a resigned shrug, and said he’d touch up the edges of his tools before he left. So at last I got to witness the Apolinarian mysteries of sharpening.

He disassembled his three planes and lined up his six or seven chisels. From under his bench he produced a dirty 8/4 board, about 16 in. long and 6 in. wide, with a cleat nailed along the bottom, like a keel. He reached under his bench again and came up with a small cardboard box, which was fairly filled with neatly cut strips of, God forbid, sandpaper — 240-grit, 400-grit and 600-grit aluminum-carbide wet/dry paper, to be precise. He clamped the board up in his vise, squirted some viscous fluid (which I later found out was a mixture of motor oil and kerosene) on the surface and spread it around with his fingers. Then he took a strip of 240-grit paper, patted it flat onto the oozing surface of the board and secured it there with two thumbtacks, using the same timeworn holes. He squirted some more fluid on the paper and began to hone one of his plane irons.

He was fast, taking no more than 15 seconds or so to have done with the bevel. He followed with his other plane irons. Next came his chisels. When the paper stopped cutting, he’d put on a fresh piece. Stage two — 400-grit paper. He went through the same routine as before, making sure the paper was kept wet with the oil/kerosene mixture. Then came a final round with 600-grit paper, which went the same as the first two stages. This time, though, he finished each tool by flipping it over and backing it off — holding the back of the tool flat against the abrasive surface and rubbing back and forth for several strokes to remove the wire edge that results from honing the bevel.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Metabo HPT Impact Driver (WH18DBDL2)

Milwaukee Cordless Shop Vac (0880-20)