Choose a Quality Entry Door

A hard look at the features and components that enhance a front door's energy efficiency, durability, and aesthetics.

Synopsis: Choosing an entry door involves considerations such as budget, aesthetics, and maintenance. In this article, contributing writer Matthew Teague breaks down the three types of entry doors—wood, steel, and fiberglass—and looks at the materials and techniques used in their construction. He also explains what makes a quality door, suggests where one’s money is best spent, and gives guidance on maintaining a door. Sidebars in the PDF below examine hardware options and energy-efficiency issues.

Often underappreciated but never overlooked, entry doors serve to welcome your guests, to protect against weather, and to keep out intruders. Not only does an entry door help define the architectural elements of a house, but it also helps to distinguish the owner’s style. Because prices range from $120 to the thousands, choosing an entry door involves considerations such as budget, aesthetics, and maintenance issues based on individual need more than the construction of the door.

Many of the key components that differentiate a quality door from a lesser one, however, go unseen. Efficiency, durability, and the life of a door depend on the nuts and bolts of how a door is made. Here, I’ll break down the three types of entry doors and look at the materials and techniques used in their construction. I’ll also shed light on what makes a quality door and suggest where your money is best spent.

Entry doors are constructed of wood, steel, or fiberglass, each with its own attributes and drawbacks. Besides door type, there are a few things that you’ll want to consider right away. For instance, pay attention to your local climate and the location of the door itself.

Highly exposed entrances on the south, west, and east sides of a home receive the harshest sunlight, making UV-resistance a necessity. Doors placed under eaves, porches, and other overhangs will be better protected. Most manufacturers of wood doors recommend that their doors be installed below an overhang that’s at least half as deep as the distance between the sill and the eave. If you have less of an overhang, opt for a more durable door.

Wood

Although fiberglass and even steel doors attempt to mimic the look of wood, nothing matches the inviting, warm feel and heft of a well-made wood door. Available in almost any style or species and with countless glass orientations, wood doors not only offer the most traditional look but also the most options. They can be adorned with virtually any molding profile and can even be carved. Most feature frame-and-panel construction, allowing them to expand and contract with changes in humidity without sacrificing the door’s strength.

Although fiberglass and even steel doors attempt to mimic the look of wood, nothing matches the inviting, warm feel and heft of a well-made wood door. Available in almost any style or species and with countless glass orientations, wood doors not only offer the most traditional look but also the most options. They can be adorned with virtually any molding profile and can even be carved. Most feature frame-and-panel construction, allowing them to expand and contract with changes in humidity without sacrificing the door’s strength.

Construction

Although some wood doors are doweled together, those constructed with traditional mortise-and-tenon joinery fare better over time.

Core

Most modern wood doors feature a thick veneer (1/16 in. is fairly standard) attached to the faces and sides of an engineered-wood core, which minimizes warping and helps to extend the life of the door. Core materials used for the stiles and rails vary among manufacturers, but better doors have stave cores (1-in. strips of wood glued together) with the same species of wood used throughout. Using the same species makes the door more stable because the expansion and contraction rates of the core and veneer are consistent.

Panels

Panels are traditionally left unglued to prevent cracking as they expand and contract within the frame, but some manufacturers now use an elastic sealant to prevent air and water penetration in these critical areas. If energy efficiency is a concern, look for panels that have wood laminated over an insulating core.

Finish

Wood doors can be painted, stained, or clear-coated. If you’re finishing the door yourself, opt for an exterior-grade oil-based varnish or polyurethane with good UV-protection. If you stain the door, apply a minimum of two UV-protecting topcoats. Factory finishes are often a better option. They are applied under optimal conditions and generally offer better protection than those applied in the field. Also, many manufacturers finish the panels before construction so that as wood expands and contracts with the seasons, it won’t expose an unfinished “tan line.”

Maintenance

A downside is that wood doesn’t stand up well to the elements. If your door will encounter excessive sun exposure or has an insufficient overhang, frequent maintenance and refinishing will be required. Depending on climate and exposure, wood doors may need to be refinished every one to three years. While a wood door can last a lifetime if cared for properly, a neglected one may last only a few years. Because the life of the door is so dependent on maintenance, most manufacturers offer only one- to two-year warranties on wood doors.

Steel

Steel doors are a good choice when budget, durability, or security takes priority over looks. Steel doors are available with a frame of wood, an engineered composite material, or less often, steel sheathed on both sides with skins of molded steel. In terms of aesthetics, steel doors come in a variety of styles, though not as many as wood doors. While a steel door might not be the first choice for a traditional home, it can look perfectly fitting on a more contemporary design. (For more on design considerations, see “Drawing Board,” p. 104.)

Steel doors are a good choice when budget, durability, or security takes priority over looks. Steel doors are available with a frame of wood, an engineered composite material, or less often, steel sheathed on both sides with skins of molded steel. In terms of aesthetics, steel doors come in a variety of styles, though not as many as wood doors. While a steel door might not be the first choice for a traditional home, it can look perfectly fitting on a more contemporary design. (For more on design considerations, see “Drawing Board,” p. 104.)

Construction

Although instinct may point you toward a solid-wood frame, engineered or composite frames are more stable and less likely to warp over time. Steel frames on higher-end or safety doors are even stronger.

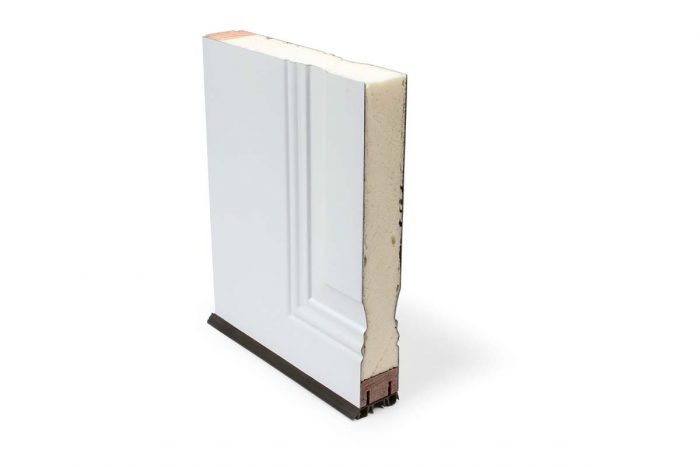

Core

The foam core is made of either sheet polystyrene, which often leaves air pockets, or sprayed polyurethane foam, which expands to fill air pockets. For maximum energy efficiency, opt for sprayed polyurethane foam. Some core materials help to achieve high fire ratings, which are useful in high fire zones or multifamily housing.

Skins

While some steel doors are embossed to mimic wood grain, few—if any—are convincing. Although some argue otherwise, it is often best to accept a steel door as just that, choosing simple patterns with minimal molding profiles. Most residential models are made of 24-ga. steel; stay away from anything thinner. Builder grades are often 26 ga., while high-end doors can be as thick as 20 ga. Dents, which are less likely on thicker-gauge steel doors, can be repaired with auto-body filler, and minor scratches can be sanded away and repainted.

Finish

Factory finishes are available, but new doors usually arrive primed and ready to paint. Factory-applied primers are usually a durable, baked-on polyester finish—better than the average homeowner can apply in the field.

Maintenance

Depending on the quality of the finish and exposure to the elements, the average steel door will need repainting every three to five years. Don’t put off maintenance on a steel door: Once the surface finish becomes compromised, the steel deteriorates quickly. To prevent corrosion, repaint whenever the coating begins to crack, flake, or peel. Because corrosion is a concern, steel doors are not a good choice in any coastal environment.

In the right conditions and with proper maintenance, which is minimal, a steel door can last as long as 50 years. A midlevel steel door typically comes with a five-year warranty. Of all door materials, steel is the least expensive. Adorned with all the amenities of an entry system—door frame, sidelites, hardware, and so on—prices begin to rival wood.

Fiberglass

Over the past 10 years, most door advancements have come with fiberglass because it offers the most promise for advanced performance. It’s strong and won’t crack, dent, or warp. A quality fiberglass door can look perfectly fitting on the front of even a traditional home. Except for custom-made wood doors, fiberglass doors are now manufactured in the same wide array of styles and with similar glass options.

Over the past 10 years, most door advancements have come with fiberglass because it offers the most promise for advanced performance. It’s strong and won’t crack, dent, or warp. A quality fiberglass door can look perfectly fitting on the front of even a traditional home. Except for custom-made wood doors, fiberglass doors are now manufactured in the same wide array of styles and with similar glass options.

Construction

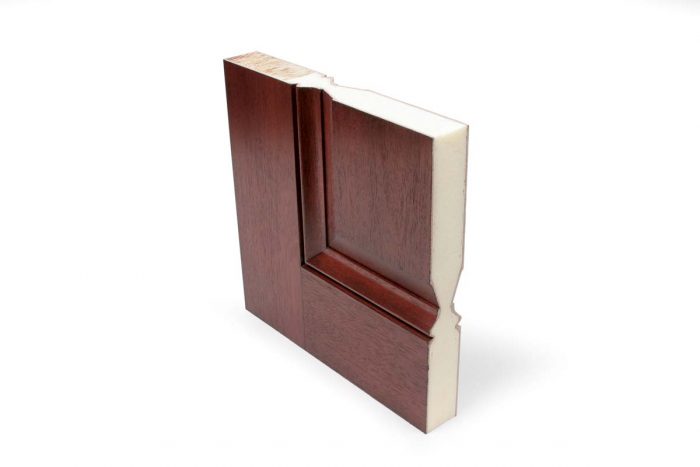

Manufactured similar to steel doors, the frame that the fiberglass skins are applied to can be made of a wood composite, LVLs, and even steel to prevent twisting and warping. While steel frames are the strongest, composites and LVLs offer plenty of strength for almost any application. Frame joinery varies, but seldom is it a consideration because there is rarely any joint failure in a modern sheathed door.

Core

As with steel doors, fiberglass doors are filled with a foam core that can be in either sheet or spray-on form. Again, spray-foam filled doors are superior performers.

Skins

While you can buy inexpensive fiberglass doors with smooth faces, more innovative modern doors are textured to look like real wood. Although cheaper and earlier fiberglass graining looked inauthentic, better doors are now manufactured using molds made from actual wood doors, making them almost indistinguishable from real wood when painted or stained.

Finish

Factory finishes are available in either paint or stain, but you also can buy doors unfinished or primed and ready to paint. As with other doors, factory finishes are applied under optimal conditions and tend to last longer than field-applied finishes. Some manufacturers—Therma-Tru, for instance provide stain kits to complement their fiberglass offerings.

Maintenance

Keep the door clean, and restain it every two to three years with an exterior-grade finish. To strip the door, you don’t sand fiberglass. You essentially rub the stain off with chemicals and a rag. Finish scratches can be repaired by refinishing; deep scratches can be repaired with products akin to auto-body fillers. Because they’re so durable, fiberglass doors come with warranties of 10 years or longer.

Hardware Options

Aesthetically, hardware is about personal preferences, but you should consider the mechanical differences between the hinges and the locking mechanisms.

Entry-level doors generally come with standard 4-in. by 4-in. butt hinges. On heavier doors, including most wood doors, look for larger 41⁄2-in. or 5-in. ball-bearing hinges. Spring hinges are sometimes an option on higher-end doors. They have a wound spring inside a large barrel that makes them self-closing. Adjustable hinges are another option. They’re mortised into the edge of the door and allow for both vertical and horizontal adjustment so that if the door sags over time, you can move it back into alignment. While simple butt hinges can cost less than $1, high-end adjustable models run between $14 and $20. With hinges, you usually get what you pay for, so splurge on the most expensive hinges your budget will allow.

Standard single-point locks work as you’d expect. The door locks into a single plate on the handle side of the door frame. Higher-end entry doors come with multipoint locking systems that secure two or more sides of the door to the frame. Some multipoint locks engage the threshold, door frame, and header, while others simply engage the jamb at the top, middle, and bottom of the door. A multipoint locking system not only makes your door more secure, but it also helps to keep the door aligned with the door frame to prevent twisting and warping. A multipoint lock also provides even pressure between the door and its weatherstripping, creating a better, more airtight seal.

|

|

Hinge performance. Choosing the best hinge may not seem like a big deal, but using an inferior hinge is. Select a ball-bearing hinge (left) whenever possible and an adjustable hinge (right) on heavier doors, which are more likely to need realignment over time.

Energy Efficiency

In terms of efficiency, an exterior door works in conjunction with the door frame, threshold, and weatherstripping. While the door itself has an R-value, air penetration around the door is the biggest threat to its energy efficiency. Prehung doors arrive with the door and frame already hinged and properly weatherstripped, and some even come with all the hardware installed. Even so, it’s important to be sure you’re purchasing a door with the best performance possible.

In the door

Fiberglass and steel doors with foam insulation are said to be as much as six times more efficient than traditional wood doors. Most wood doors are not even Energy Star-rated, but because all three types of doors are able to achieve some Energy Star qualifications, it’s important to shop wisely. Although it seems counterintuitive, the most energy-efficient wood doors are usually the ones with the most glazing because low-emissivity (low-e) glass is a better insulator than wood. A basic wood door is around R-2, while the most efficient wood doors are around R-5. Fiberglass and steel doors are typically closer to R-8, but can run higher.

|

|

Around the door

Look for weatherstripping that fits into a kerf milled into the frame. Often called Q-Lon (a manufacturer’s name), this style of weatherstripping is made of foam and is covered with a nylon jacket that springs back into shape. It’s also less likely to tear or deteriorate than some other types. Q-Lon stays in place longer than adhesive-backed weatherstripping and resists compression set, which is common with some rubber products.

|

Below the door

A door sweep seals the lower door rail to the sill. Common door sweeps feature a metal channel that screws to the bottom of the door and a rubber gasket that slides onto the metal. Although they’re not common, stay away from bristle-type sweeps. Because rubber gaskets may tear or become damaged over time, look for a sweep that allows you to replace the gasket without removing the door from the hinges.

|

For more photos and a breakdown of steel and fiberglass entry doors, click the View PDF below.