1/2″ Vs. 3/8″ PEX design Issue?

| 3239.1 | |

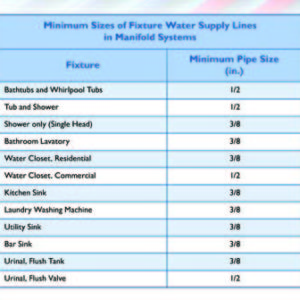

| Hello All, Here’s the situation. I’ve got a situation that seems to be perfect for a pex home-run manifold. I’ve got 2 bathrooms, a small kitchen, and a laundry room all with ~10′ (as the crow flies) of the manifold location. The Plastic Pipe Institute has a Pex Design guide which I have read and which has this very handy table. see attached-can’t figure out how to get it to show up inline? From reading the table it seems like just about everything but high use situations would be ideal for 3/8″ PEX. I love the idea of using 3/8″ instead of 1/2″ because. 1. Its cheaper per foot. I do know something about working with 1/2″ PEX having installed over 2000′ of it already in my radiant heating system. I’m all set to work up a parts list and I download the Wirsbro/Uponor catalog…. They don’t make ANYTHING in 3/8″ basically…no manifolds, no angle stops, just some adaptors to go from 3/8″ to 1/2″ and the tubing of course…. What gives? Do I just suck it up and use 1/2″ for everything paying more for the privilage of a harder install? Has anyone else come across this issue and how did you solve it? Does the plastic pipe institute have it wrong? Am I missing something? I mean, 1/2″ to a freaking icemaker? Really? Any useful advice would be greatly appreciated…. Mads |

Replies

Huh

Here's a different version of the table.

PexSupply.com seems to have everything in 3/8, except for the end fittings. I suspect they are bowing to a market that doesn't trust there will be enough watter flowing through a 3/8" pipe to supply an ice maker!

I think you just need to buy a handfull of 3/8" to 1/2" pex adapters, or just go with threaded 1/2" valves and use 3/8 pex to 1/2" NPT fittings.

EDIT: http://www.houseneeds.com/shop/plumbing/pexplumbing/vanguard/vanguard38inchbuy.asp This place has 3/8" fittings!

Dont

want to switch from the Uponor system.

I have access to the tools required and I think its a better system.

They do seem to have some end fittings in 3/8" so it looks like I'll just need to step it down at the manifold from 1/2".

>>>I mean, 1/2" to a freaking

>>>I mean, 1/2" to a freaking icemaker? Really?

Perhaps.

But your rational of "Its cheaper per foot." might be a bit misplaced. Consider the overall cost of a bit of pipe in the context of the whole job. It's like a cup of water from a well, to keep the analogy within the plumbing context.

If there is the least bit of concern for water throughput, I'd stay with 1/2" for all homeruns.

And I would imagine that code doesn't permit 3/8" pipe in many parts of the country.

We're under

The CPC here which is based on the ICC plumbing code....

I have to admit that my eye's glaze over and my brain turns to mush just thinking about looking something up in the code books...

Mads

There are two advantages to home runs, and using 1/2" where you don't need to negates one of them.

The first advantage is being able to isolate and possibly shut off any water run from a central location.

The other advantage is a reduced volume of cold water in the hot water lines that has to be run out before the water is useful. With 3/8", you spend less time running water in the sink before it finally heats up and you can use it. Same for the dishwasher.

You don't need 1/2" pex to run a normal bathroom sink. To fill a tub - that is another matter. But if I had my choice, i'd choose to wait less for the hot water before I took a shower.

Point Taken

I'm trying to learn to do this correctly and I'd think that a design guide put out by the plastic pipe institute would not steer me wrong?

Here's a link to the design guide.

http://plasticpipe.org/publications/pex_handbook.html

Really the point is to not spend money that I don't have to...in any large project you have to keep a clamp on expenses so that they don't run away from y ou right?

Mads.

Just as few anticipated the ways that 'the internet' would change our daily lives, few fully understand the way PEX changes the way we do plumbing.

You've hit on it - the assumption that plumbing starts with 1/2" pipe. Naturally, we're also in the habit of looking at plumbing layouts as if they were trees - with a large trunk branching off to smaller and smaller sizes as we go along.

This was best illustrated when Fine Homebuilding did an article on residential fire sprinklers - they illustrated both of the permitted methods assuming a conventionally laid-out household plumbing system. This is ironic, in that one common material used in residential sprinklers is PEX. (The orange stuff).

Changing to PEX is about far more than just using "another material." The whole point of PEX is to avoid fittings between the manifold and the appliance. "Home runs" all around. Thus, 3/8 is plenty big, maybe even for filling bathtubs. A smooth inside and sweeping bends equals greater flow being available. Indeed, I suspect most faucets would be happy with 1/4" (assuming it existed). In areas with low water pressure, the use of a small booster pump is a lot more attractive when every run is a home run (fewer opportunities for leaks, and the ability to close off a run to work on it.)

As for the manifold, this is the one place where you want there to be plenty of capacity. I suppose it's reasonable to have to 'step down' to 3/8, since the same manifold will likely supply both 1/2 and 3/8 lines - and there's no telling where the 1/2 lines will be landed.

Well Said

Seems like plumbers don't understand exactly what they're dealing with and trying to apply their wisdom gained with copper to a different system.....

Mads

I've Found The Answer!!!!

So it turns out the Uponor has a online forum. I asked in that forum the same question that I asked here...and here is what the Uponor employee said....

dneumansky,

Due to the fact that 3/8" piping is minimally used in the plumbing industry & markets are moving away from 3/8" piping, our demand to manufacture 3/8" fittings & components at a competitve price is not feasible. Uponor does not promote plumbing with 3/8" because of increased head loss & velocity (noise) through piping. Uponor Logic plumbing w/ 1/2" fixture drops greatly reduces hot water delivery times, head loss & install time.

ThermalX

So, there you have it....they couldn't make enough money selling 3/8" stuff so they're pushing the 1/2" as a standard...not that 3/8" isn't up to the task....

super

Mads

Reply from Plastic Pipe Institute PE

3239.55 in reply to 3239.20

Here's the reply I got back from the PPI PE...

Hi Daniel

You are welcome – Pls see the discussions below and hope that is helpful for you-

.. in addition to the ice maker, dishwashers are most often supplied with nominal 3/8” tubing. The IPC (see Table 604.5 in the 2009) permits smaller tubing size as part of a manifold system for specific fixtures and includes length an minimum pressure parameters. The Table on page 75 is based on the IPC – Also, per engineered designs, the pressure loss and velocity calculations can easily be performed and shown to fit within the manufacturer’s recommendations as well as limits in some local codes, based on actual fixture flow rates and available pressure.

Also, kitchen faucets, lavatory faucets and showers are all flow limited devices. Showers are the most at 2.5 gpm. Faucets are 1.5 gpm. Refer to Tables 3.2 and 3.3 which give flow velocities and pressure losses. For a very compact plumbing layout with 10-20 ft. of pipe between the manifold and fixture, even at 2.5 gpm, the pressure drop in 3/8” tube is only 8 psi. Since most water systems deliver water at 40-80 psi there is ample pressure available to deliver the water.

So I guess the answer is, yes 3/8" will work but pay a PE to prove it? I would love to learn how to do those calcs just to figure it out for myself...anybody know where I would go to learn something like that?

Mads