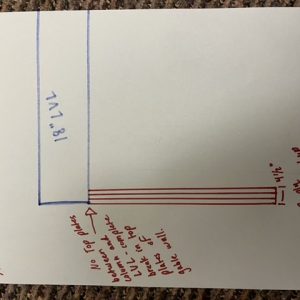

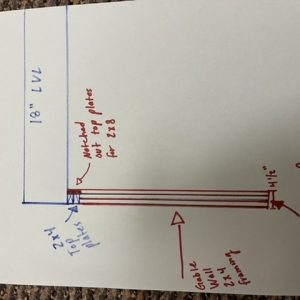

18” LVL Support.

Please advise which of the two framing techniques is best practice. Option A or Option B. Or if there is another better way please fill me in, thanks!

Option A cuts out the top plates below the lvl and the column runs from bottom plate up to the lvl. This puts a complete break in the top plates of my gable wall.

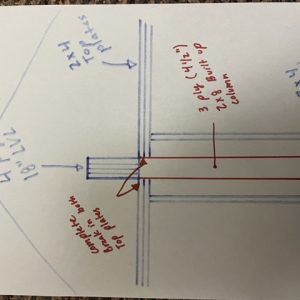

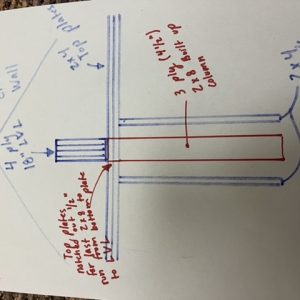

Option B leaves the top plates but notches out a half an inch for the last ply of the 2×8 built up column. This leaves my top plates in tact for my gable wall but has part of the lvl supported through the top plates and part of it by the last ply of the 2×8!running all the way to the lvl.

Replies

This is not engineering advice, but couldn't you put say five jacks in the wall and keep everything flush?

I'd probably include whatever squash blocking that's needed under the floor. (area in red)

The minimum bearing length on each end of the lvl is 3.9 inches per the engineer, which is why the 3 ply 2x8 column is being used. I wish I could just pack it with 2x4s.

Your engineer didn't detail this out for you? He or she should be providing details and fastener schemes. It really does matter.

My lumber yard works with an engineer. I give them the necessary details and they give me the beam size. They did not provide the column details. I didn’t hire an engineer for this remodel.

Thanks for the added info. I wonder if this would work then? I really hate cutting top plates.

That’s my “Option B”- to have 2 of the ply’s under the top plate and the third run on the outside of the 2x4 wall up to the lvl.

Are you going to drywall around the column, or bump the wall out to hide it?

It also seems you could make the wall 2x6, and under the column, use a stack of them (2x6) under the LVL (with the top plates intact)