Trying to adhere to the manufacturer’s specs for the installation of their 5V metal I’m having some concerns I hope to resolve.

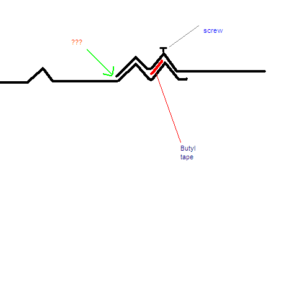

According to the diagram you can see the recommended screw, tape, and panel installation.

However, when installing in this manner it seems that where the (???) panels meet, the top panel edge (???) doesn’t lay nicely on the bottom panel. In fact no matter what is done it is definetely raised enough to grasp with ones fingertips.

I’m assuming the butly tape is a last resort for keeping water from getting beyond the anti-syphon chamber onto the underlayment. However it appears to be the cause of the raised edge.

In previous applications I haven’t used the tape (shed’s and other structures I wasn’t concerned with warranty issues) I installed the panels in the same manner and they laid nice and flat, and have yet to leak (even with near hurricanes).

So, I don’t want to void any warranty for failing to install according to manufacturers specs:

This raised edge (approx 1/8″ +/-) will it catch wind and rip the panels off/bend them?

Is having the tape necessary to allow water/moisture to properly exit the anti-syphon chamber?

Wouldn’t it in fact allow more water to get into the chamber more easily, and put most of the water retarding reliance on the butly tape?

Water stoppage is the key here where I live, and then wind (most of the time they are hand in hand)

Please let me know your thoughts.

—————————————————————————–

WWPD

Replies

Who's the manufacturer? Do they have a web site? I don't like that design at all, either. One of the big advantages of metal as a roofing material is being able to blind fasten it.

-- J.S.

Sailfish,

Butyl tape does not work. It dries, shrinks and cracks in less than a year. Does more harm than good.

We also don't screw on the ribs. Both of the suppliers we use show screws on the flat. SEMCO and Metalsales.

Could not get SEMCO site to work but here is Metalsales.

http://www.mtlsales.com/Products/5vCrimp.pdf

KK

I can't understand why they tout the tape if its worthless though. Seems odd.

Here is the company they do not have the spec sheet on the web however I received it manually

http://www.gometalroofing.com/home2.htm-----------------------------------------------------------------------------

WWPD

The Metal Sales detail does not call for buytl tape. They do use it with corrugated, thought.

Are you using screws or nails to fasten the panels to the roof? In 1997, I built a house and barn in Homestead, Fl. The 5-V crimp was made by Southeastern Metals. I used one metal panel as a template for drilling a lay out or pattern for scewing the metal down. I didn't use the tape between the panels , instead I used a caulk/adhesive that was made for the galvalume panels. By holding down the top panel onto the bottom panel with one foot and then screwing in the screw to the roof , it made a tight connection. I forgot to mention, when you drill your pilot holes in the panels, turn the panels upside down so your drill bit will stay centered as it is easier to drill in the bottom of a V than to drill on top of an A. Don't drill a hole in the edge of the panel that sits under the next, upper pannel. I'm not sure if this will help you but it made for an easy job with my install. Good luck.