Affordable vapor control in mixed climate? Need help

Hi folks,

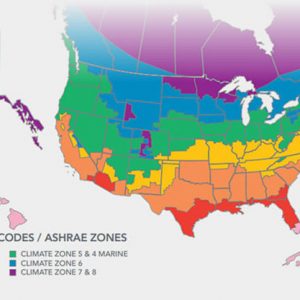

I’ve never posted on a forum before but I feel this is my best bet! I’m in the process of designing a passive house and I can’t seem to find an affordable wall assembly that works in climate zone 6. Here’s more info:

– Its a 30’x30′ two story passive house with a flat roof on screw piles.

– Our climate is heating-dominated with 2 months of cooling during summer. Temperature ranges anywhere from -22F to 86F .

– Building inspector is asking a class 1 vapor barrier right behind the drywall.

– Code is asking a class 1 or class 2 vapor barrier.

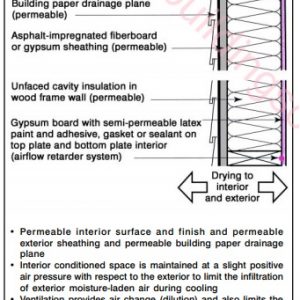

– ASHRAE recommends a “flow through wall assembly” with a semi-permeable vapor retarder (gypsum board with latex paint).

– Typical walls here are made of drywall/polyethene film/2×6/fiberglass batt/plywood/tyvek/rain screen/siding. So the vapor barrier is on the wrong side of the wall during cooling season, this is what I’m trying to avoid.

– I considered Joe Lstiburek’s “perfect wall” but the rigid foam and rock wool makes it the more expensive option.

– I’m still considering Lstiburek’s “ideal double-wall” but all passive houses I know of around are using a modified, cheaper version. i.e. they removed the sheathing on the exterior of the inner wall and taped/sealed the exterior sheating of the outer wall instead. I’m still hesitant on this.

– I ran hygrothermal analysis with U-WERT (www.ubakus.de/) and the results are confusing… The typical wall with poly is working great while ASHRAE’s wall, Lstiburek’s double-wall and modified double-wall are condensing in the wall and won’t dry. (I may be the problem here!)

So, what are your thoughts? how would you control vapor diffusion?

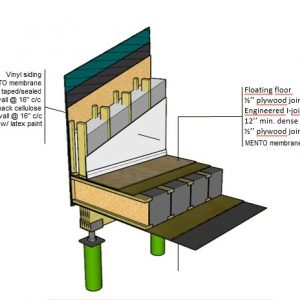

Here’s my assembly of choice so far:

– Drywall with latex paint

– 2×6 bearing wall

– 2×3 cavity wall

– 12″ dense pack cellulose

– OSB taped/sealed

– Solitex MENTO membrane

– Vinyl siding

Thank you in advance for your help.

attached: climate zone map, wall sections

Cheers,

Michel

Replies

I live and build in very humid Nova Scotia (same temperature variations). I am using 1.5" of extruded polystyrene on the interior surfaces of 2X6 fibreglass-filled walls. Strapping then runs horizontally 2'OC to carry interior drywall. It gives a good thermal break, eliminating condensation - and is very quiet. Blue tuck tape on the xps joints. Acoustic caulking where it can't be taped. Works good, 1 year in.

On the ceilings, I use 6 mil polyethylene lapped and taped with R-56+ insulation above. Scissor trusses get 1.5" polystyrene cut to fit exactly and tapped into voids in the webbing - labour intensive, but I have a good source of polystyrene - much cheaper and better than all other alternatives for me at this time.

In zone 6 you don't need to be all that worried about summertime vapor barriers. Just avoid a double vapor barrier.

QR,thanks for sharing your experience. Your house must be really quiet. Unfortunately, extruded polystyrene is too expensive here and I'm trying to keep the labor as simple as possible.

DanH, you're probably right. I

haven't heard yet of people having issues conditionning with the VB on the inside. Would your recommend using 6 mil poly or a smart membrane?

I would recommend whatever you can install reliably, with minimal leaks and penetrations. There may be a slight advantage to a "smart membrane" in warmer climates, but any advantage would be negligible in Zone 6. I live in southern Minnesota, and I've never heard of anyone having problems with condensation in the walls during the summer.

Actually, I've done 3 houses this way. I now use full 2" rough-sawn strapping so I can run the wiring through wire mesh fencing that lays under the strapping and against the interior side of the xps. All electrical boxes are plunge-routered 1" into the XPS so that very few things ever penetrate to the outside. Vents: dryer, bathroom, air exchanger, range hood, & electrical service to the panel, cables to outdoor receptacles and lights, and air-air heat pump are the only things that penetrate the xps vapour barrier. Yes, higher cost up front, cheaper over the long haul. Along with the adding of more efficient windows, I completely gutted and placed an addition on one home - tripling its square footage; the heat bill was cut in half. I fully agree with DanH that your money is best spent putting together an impenetrable interior VB. Make sure the joints are properly taped and caulk any joints where the membrane may not be continuous (like up to and under the vapour barrier between a bottom plate and a floor) had someone failed to foresee the need to run some 6-mil poly strips to join floor/ceilings to walls or one storey to the next around the rim joists. I have a good relationship with my local building inspectors. If you want to do something like I have with xps in the future, clear it with your local bldg. dept. first.