an idea for boxing in duct work 80″ span

HOPEFULLY THE PICTURES I ATTACHED ARE INCLUDED.

Here’s the situation: a guy wants his basement finished. I need to box in the steel beam and duct work. There are two ducts side by side with about 1 1/2″ clearance between for 4′. The distance from steel beam to the edge of the duct is 80″.

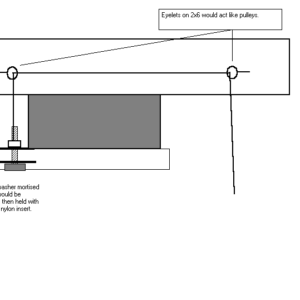

I will install framing along the steel beam and duct work. For the tight 4′, I’m going to install a 2×6 above the beam and duct work and sister to the exisiting joists. I will put two eyelets on the 2×6 before doing this. Through the eyelets I will install suspened ceiling tie wire. I will drill and mortise the OSB panels to accept a hex head bolt. The tie wire will be secured to the hex head bolt by a washer and nut. The tie wire can then be pulled through the eyelets allowing me to raise the OSB. The tie wire will then be secured to an eyelet. Please look at the drawing, it will hopefully explain. This will result in a 40″ span.

The only weight on the OSB will be itself plus 1/2″ drywall or 5/8 if I decide to use instead.

Maybe I’ve had too much coffee today. Criticms or improvemnts welcome. Thanks

Dave

Replies

Dave,

I have been building alot of basement soffits lately and this is the way I am currently doing it.

1. I nail a 2x4 to the floor joists along the plenums or whatever the obstruction is.

2. Find my lowest point of the duct and measure that from floor joists.

3. Rip OSB to that measurement plus 2" and nail to 2 x 4 nailed to joists.

4. Level from bottom edge of OSB to wall and install 2 x 4 nailer on wall 1 1/2" up from level line.

5. Layout cut and install 2 x4 16" o.c. Nailing into ends through OSB, and up into nailer along wall.

This has proven to be quick and is quite sturdy. It also makes for nice straight soffit lines. I don't know if this method will work for your situation, but it has worked great for me. If it sounds feasible I could draw it and post it ( Maybe )

Cole

Cole Dean

Dean Contracting

Cole,

I like the idea of running the OSB on the vertical part of the soffit. It sounds faster than building a "ladder" out of 2x4. Not to mention saving a little space.

My concern for the situation on this job is the 80" span. Maybe I'm being too cautious, but I don't want to see that OSB and ultimately the drywall sag.

Thanks for your input, I will definately try your soffit framing method.

Dave,

What is the measurement from the bottom of the floor joist to the bottom of the duct?

What is the with of the two peices of duct and the steel?

If your not comfortable with plywood 80", depending upon your height of the duct, you can use a 2x10 or 2x12 on both sides or 1x10 or 1x12 and then nail plywood on the bottom.

That will give you a little more head room.

I noticed in the picture a vent, you have to extend that through to. I also noticed little black buttons, that means someone had the duct work cleaned.

Let me know.

Joe Carola

From the bottom of the Joists to bottom of the duct = 9 1/2"

Width of steel to outside of second duct is 80"

Joe, if I use 3/4 plywood for the bottom of the soffit, don't you think that it would sag due to 80" span?

I know about the lowering the vent, but I didn't know the black buttons meant the duct had been cleaned. thanks for the info

Dave

Dave,

Is it an 80"x 80"sqare box ?

If this is the case, you said that you have 9-1/2" in height, so then you can use a 1x12 or 2x12 on both sides and nail some 2x4's in between for supporting the plywood.

I thought that it was 80" in length and maybe 2' or 30" in width.

Let me know.

Joe Carola

The "box" would be 80" x 36". The 80" is from steel beam to outside of ductwork. The 36" is the length where the two ducts almost come together to where they connect to the furnace. My concern was being able to get the drill or gun in between. I think I will rip the pieces to a size that will fit, and use one of those long #2 phillips bit.

I considered securing the OSB to the duct, but I'm trying to avoid that.

Thanks all for the help.

not for this job your doing but there have been a couple times in the past I've screwed the rock right to the duct. Not 80" but far enough. People want headroom but want to save $$$. Just a matter of framing a ladder from the cieling to flush with the bottom of the duct. Hope that helps sometime in the future.

listening for the secret.......searching for the sound...

Dave,

I box using Cole's method...ripping plywood for verticals and the underneath soffit panel....2x2 or 2x4 nailers attached at top and bottom of vertical panels...top nailer attached to ceiling joists...bottom soffit panel screwed to bottom vertical panel nailer.

You say your soffit panel must span 80 inches? You also indicated that the 2 ductworks were seperated by 1-1/2 inch gap? If so, then instead of relying on tie-wire , why not screw or nail some 2x2 s vertically to the above ceiling joists betweeen the ductwork? Let the 2x2s hang down, attach a 2x4( running flat) to the bottom of each 2x2 "hanger." Install your bottom soffit panel by nailing plywood into each vertical panel and also nail the soffit "down the middle" into flat 2x4 nailer.

If it was me, I'd use 5/8 ply and would screw the flat 2X4 to the hangers, and would also screw the entire bottom soffit panel rather than nail. I'd nail the side panels to the nailers, but would screw the top nailer to the ceiling joist; rather than nail. I like the holding power of screws in these circumstances.

If the gap between ductwork makes it awkward for attaching the vertical 2x2 hangers, you could pre-attach the verticals to a horizontal 2x2 (a ladder frame minus one rail) and then screw this horizontal piece to the bottom of each ceiling joist. Let the hangers hang down about an inch shy of your finished box. Mount the two vertical panels ( one side next to steel beam, the other panel 80 inches apart next to ductwork) and then run a stringline between to establish your height for the bottom 2x4 hanger. You could install 2x4 by screwing it on the side of each 2x2 hanger; rather than installing it flat underneath. 2X4 to be positioned at same height of stringline.

Just a thought.

LOL.

Davo