Attaching furring strips without piercing membrane!

Hello,

I have a house with a rooftop where we intend to build a rooftop deck. The roof’s parapets go up almost 5′. It is a “duplex” house, sandwiched between other duplexes, in Montreal. The roof’s membrane stretches up the parapets and covers it. Then there is flashing that caps the parapets.

The architect’s plan was to have the parapet’s, on the inside of the rooftop terrace, cladded with cedar boards. To do so, we have to install furring strips against the parapets.

The architect specifies that the furring strips must be installed without piercing the membrane of the parapets.

I have asked our GC, the roofing company and even called the membrane company (Soprema) and everyone seems to be puzzled by the architect’s requirement.

Is there something I am missing here?

Thank you for your help.,

Charif

Replies

Have a stainless steel bracket made. U shape with a long side of the U maybe half the distance from top of parapet to bottom. Screw cedar furring strips to bracket. Mount the brackets 16" oc over top of parapet. Nail or screw cedar 1x6 horizonally to furring.

Since it is the architect's requirement, I would ask the architect how this is to be accomplished. If he/she does not know how, then perhaps the requirement needs to be rethought.

When I asked the architect he turned it back at me and

said ask your contractor who in turn said it is not feasible.

Kinda stuck in between the two.

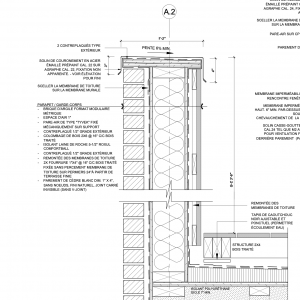

I posted the architect's drawing. The cedar is installed vertically.

So we need two furring strips, the first one is vertical

and the second one is horizontal.

Been there. Architect shows something impossible to build - when asked how, the response is something like "Build it as I want it - it's not my problem as to how to get there." "Even worse is the ambiguous detail that, when questioned elicits a response of 'I'm not sure yet but I'll know it when I see it.'"

Is the parapet's vertical membrane adhered to the substrate? Perhaps there's an adhesive that will bond between the membrane and the furring strips. Some of the liquid flashing material may develop a reasonable bond. I cannot read or speak French so I can only judge the picture and not the words on the detail.

Architects draw unbuildable things all the time. The fact that your architect can’t provide a detail to explain how to achieve their vision tells you everything you need to know about their understanding of how buildings are put together. They aren’t a problem solver; they’re a problem maker. If the membrane isn’t in place yet, there are plenty of standoff options that can be integrated into the membrane. If the membrane is already installed, an option might be to find an adhesive that’s compatible with the membrane. Build the cedar cladding/furring assembly on a bench and then adhere the assembly to the membrane.

Edit: hah - yankee beat me to it

From the drawing you added to the original post, it would seem possible to assemble the cedar wall and hang from fasteners that penetrate the two layers of exterior plywood at the top. Longish screws can be sealed on the top after hanging, and would be covered by the cap.

Seems like it would be a better idea to equip the bottom furring strip with whatever is specified under the decking 2x4 supports to maintain the vertical orientation against and away from the parapet wall.

(Don't suppose you have a version of this drawing in english, do you?)

Unless my French is deceiving me, the label reads "...without piercing the roof membrane for the first 24" above the finished deck. From the parapet dimension of 3'-6" total that would give you about 1'-6" at the top of the vertical furring to put your fasteners - then construction adhesive the remainder or just leave it if they are tight enough in place.

I would confirm with them if that is the intent.

That's how I read this: Attach the vertical, but not the first 24" from the "floor" level.

Depending on the spec for the membrane, these things are pierced all the time. Some are “self healing,” and designed to have fasteners go thru them. Also think about how mechanically attached membranes are literally thru fastened to be installed. Make this architect give you an answer (and I’m an architect myself.) I wouldn’t recommend adhesives. Too much chemical compatibility risk.