Hi all,

I’m planning to build what might be best described as a post and beam style picnic shelter, only it’s intended to cover a retired RV from the elements. (I live in Kentucky, what can I say?) The covered area will be about 11′ wide, 36′ long and 11′ tall, with rafters and gable roof above that.

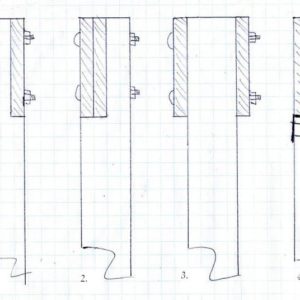

I’m thinking of using pressure treated 6×6 posts for the supports, with double 2×12’s for headers (to span about 12′) and wondering if there is a recommended way to attach the 2×12’s to the headers. Attached are 4 ways I could think of.

#1, 2, and 3 are variations using 1/2″ carriage bolts and #4 uses Simpson type metal connectors with the headers on top of the posts.

I’m partial to #2 because that leaves a space to the right of the headers for attaching collar ties, but will it significantly weaken a 6×6 to cut a 3″ rabbit out of it?

Also, what do folks think is the best way to mount the posts to the ground? Bury them in dirt or concrete, or use some type of stand-off atop a concrete base?

I appreciate any advice concerning these questions, and anything else that may be helpful!

Thanks a bunch,

Kyle

Discussion Forum

Discussion Forum

Up Next

Video Shorts

Featured Story

The Trim Coil Holder from InnovaTools makes it easy to swap out trim coil and features a reversible, built-in guillotine cutter.

Highlights

"I have learned so much thanks to the searchable articles on the FHB website. I can confidently say that I expect to be a life-long subscriber." - M.K.

Fine Homebuilding Magazine

- Home Group

- Antique Trader

- Arts & Crafts Homes

- Bank Note Reporter

- Cabin Life

- Cuisine at Home

- Fine Gardening

- Fine Woodworking

- Green Building Advisor

- Garden Gate

- Horticulture

- Keep Craft Alive

- Log Home Living

- Military Trader/Vehicles

- Numismatic News

- Numismaster

- Old Cars Weekly

- Old House Journal

- Period Homes

- Popular Woodworking

- Script

- ShopNotes

- Sports Collectors Digest

- Threads

- Timber Home Living

- Traditional Building

- Woodsmith

- World Coin News

- Writer's Digest

Replies

I like #2 the best by far.

m

------------------

"You cannot work hard enough to make up for a sloppy estimate."

#2 because the joists can be fastened together. That way you have a true double joist, as opposed to 2 single joists.

Rabbeting the 6x6 shouldn't be any problem, but let's hear what others have to say on that matter.

~ Ted W ~

Cheap Tools! - MyToolbox.net

Meet me at House & Builder!

I also like #2 the best. The notch weakens the 6x6, but it is at the end, not subjected to much bending, so what is the big deal about it? The joists are solidly supported and can be tied together and the 3x6 alongside them prevents rolling over.

So long as you use treated posts, burying them in the earth is stronger because it helps prevent racking, like a pole barn does. If they sit on top of concrete in the air, ALL the racking forces have to be resisted by diagonals or shearwalls.

Bill

#2 without a doubt

Welcome to the

Taunton University of Knowledge FHB Campus at Breaktime.

where ...

Excellence is its own reward!

I'd also suggest #2. But #1 would likely be OK also.

No way would I accept #3 or #4.

For #1 I'd use scrap deadwood for blocking to maintain a connection between the two. overall a lot more work to do that one, but can be more aesthetically pleasing in some situations.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Hmm. Everybody likes #2, but if it's exposed to the elements, those two boards will trap water between 'em, leading to premature rot. If you go with #2, some 1/4" spacers between 'em will let 'em drain.

Mike Hennessy

Pittsburgh, PA

On a deck, I'd use vycor over them, but this is up under a roof where only rare wind suction will leave a few drips on that joint.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Poor old number 4 never had a chance.

Poor old number 4 never had a chance.

#4 is just #1 without the toung in the middle, which is needed to stiffen it.

I would have voted for #4 if the rafters were moved together, get rid of the simpson ties, notch the post on one side and set them down in it, and through bolted with the 1/2" carriage bolts left over from not doing #2.

~ Ted W ~

Cheap Tools! - MyToolbox.netMeet me at House & Builder!

Edited 4/22/2009 10:16 am by Ted W.

And the answer is??? A resounding #2

If you need some engineering back up, go to link and view fact sheet #13

http://www.fema.gov/rebuild/mat/mat_fema499.shtm

I'd boom up to some 8x8's and use rough cut 3x12's for girders. Compare the price and see what ya think.

Thanks much for all the quick and mostly unanimous responses. #2 it will be!

I agree with BillBrennan regarding the strength of burying the posts in the ground, but I'm curious how long they will last compared to being above ground on concrete. (I neglected to mention the possibility that one day the RV might be hauled away and the structure could be closed in and converted to a shop or storage shed.) If I do bury them, how deep and is there any need for concrete around them?

Piffin is right about the headers - they will be under the roof and mostly out of the weather, but that brings up another question: Is there any need for the roof framing (headers, collar ties and rafters) to be made from pressure treated lumber, or would it be safe to use non-treated?

Thanks again for the all the opinions. It's very encouraging.

"Argue for your limitations, and sure enough they're yours."

p.s. Thank you all for being kind enough not to comment on my misspelling of the word "rabbet". I guess it's still too close to Easter!

Edited 4/22/2009 9:33 am ET by KylefromKy

Edited 4/22/2009 9:50 am ET by KylefromKy

Might check this site out. Pick a plan and you can see construction details.

http://www.public.iastate.edu/~mwps_dis/mwps_web/hy_plans.html#Anchor73110 here is the main page

http://www.ebackroad.com/0mwpsorg-freefarmplans.html

Edited 4/22/2009 9:46 am by dovetail97128

concrete around the post helps hold moisture and speeds up the rot.

pack it tight with tamped gravel.

Jeff

Buck Construction

Artistry In Carpentry

Pittsburgh Pa

# 2 without a doubt. I built this structure in 1988, took the pic a couple of years ago. I wouldn't worry about longevity if you put it together right.

Hi Tom,

Nice joinery for an outbuilding! It looks like you used pressure treated for the headers and rafters, is that right? Did you bury the posts, and if so, how?

"Argue for your limitations, and sure enough they're yours."

Edited 4/22/2009 11:27 am ET by KylefromKy

It's all PT. The footings were poured to ground level, and shot with a transit. Steel post bases were bolted in place, and all pieces were cut about 3/4 of a mile away and hauled up the hill on a farm wagon, and assembled there. I only needed the generator to drill bolt holes for the lumber connections. Everything else was pre-cut to length.It's at my buddy's rifle range, so whenever I go there to shoot, I take a couple of wrenches to make sure the connections are still tight.The plywood scabs you see he installed so he could have blown-in cellulose installed, sprayed up against the fiberglass (for sound absorption). After about a year, environmental conditions, plus a lot of muzzle blast, removed about 90% of the cellulose.

Thanks, Tom.

That does sound like a long lasting type of construction.I'm wavering between the relative ease of burying the PT posts vs. instinctively mounting them above ground on concrete, which seems destined to last longer. I live on a farm that's littered with decaying pole buildings, (from the 1950's and 60's, granted they're not PT) whose posts are rotted at the base and shortened by 6-12" causing the rooflines to sag and the rest of the framing to bend and break. (Sounds kind of like me come to think of it). After seeing the degradation, I'd like to make sure the buildings I construct have the best chance possible.(oh, you said wrenches, not wenches.)"Argue for your limitations, and sure enough they're yours."Edited 4/22/2009 6:51 pm ET by KylefromKy

Edited 4/22/2009 7:19 pm ET by KylefromKy

http://www.permacolumn.com/

"When the spirits are low, when the day appears dark, when work becomes monotonous, when hope hardly seems worth having, just mount a bicycle and go out for a spin down the road, without thought on anything but the ride you are taking." — Sherlock Holmes, 1896

strucurally #1 & #2 are equally strong... nothing wrong with #3 but #4 looks questionable..

What we did on our deck was to notch the top of the post, insert a piece of 5/4 decking in the notch, and then bolt the headers either side of that. This avoids creating a weak spot at the bottom of the tenon when you use the tenon method.

Hi Dan,

Thanks for the reply.

I'm having trouble visualizing that...you don't happen to have a photo or drawing, do you?

"Argue for your limitations, and sure enough they're yours."

Nothing I can do quickly. Basically, a vertical notch is made in the top of the post, as wide as the 5/4 stock is thick and maybe 8 inches deep. The 5/4 piece is inserted into the slot and thru-bolted in place, then the headers are placed on top of the post either side of the 5/4 piece and thru-bolted to it. (Obviously, with 6x6 posts you could use something thicker than 5/4, but the 5/4 worked out well for our 4x4 posts.)If you use 5/4 bullnose decking (or maybe a piece of 2x, for 6x6 posts) and use a piece that's an inch or two wider than the post it produces a fairly attractive detail.

The modern conservative is engaged in one of man's oldest exercises in moral philosophy; that is, the search for a superior moral justification for selfishness. -John Kenneth Galbraith

OK, Now I see.

Thanks!

"Argue for your limitations, and sure enough they're yours."

Yep, #2. And I'd probably skip the carriage bolts and go with GRK lags.

Under a short deck or somewhere looks didn't matter I'd go with #2, with 1/4" spacers as noted.

If this is going to be seen, I think #1 or #3 look best. I would add 2x4 bolsters under #3 though.

What can I say, I like symmetry.

Thanks for all the replies. It has been very helpful.

I'll try to post some photos along the way. I hope to start next week!

Kyle

"Argue for your limitations, and sure enough they're yours."